Power control cabinet

A technology for power control cabinets and cabinet doors, which is applied in the field of electric power, can solve the problems of improper setting position, hindering maintenance personnel from overhauling, and the lock rod assembly occupies a large space and is unsightly, and achieves reasonable and compact setting, reduced structure and occupied effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

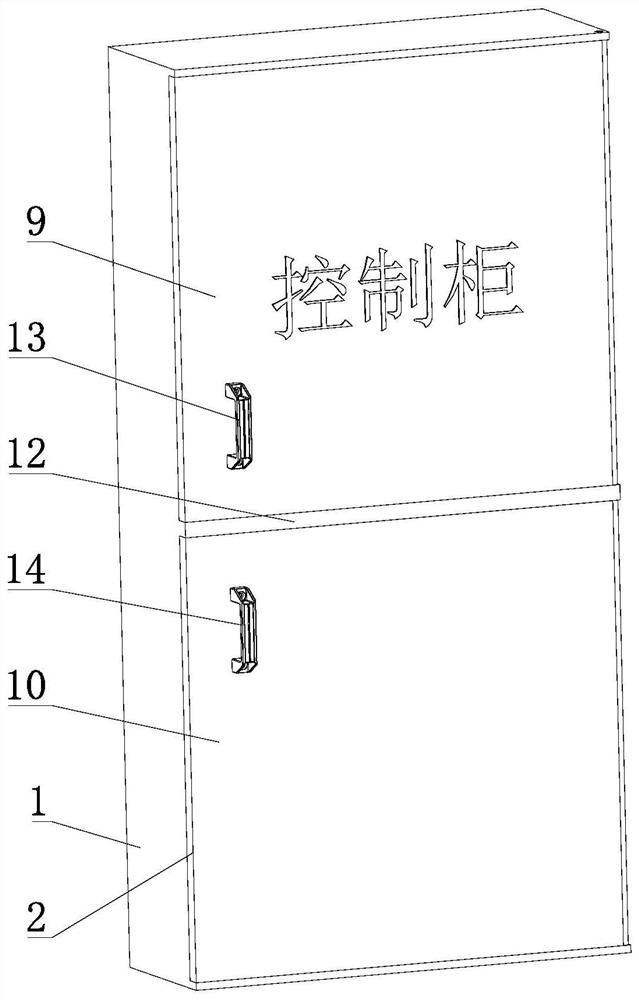

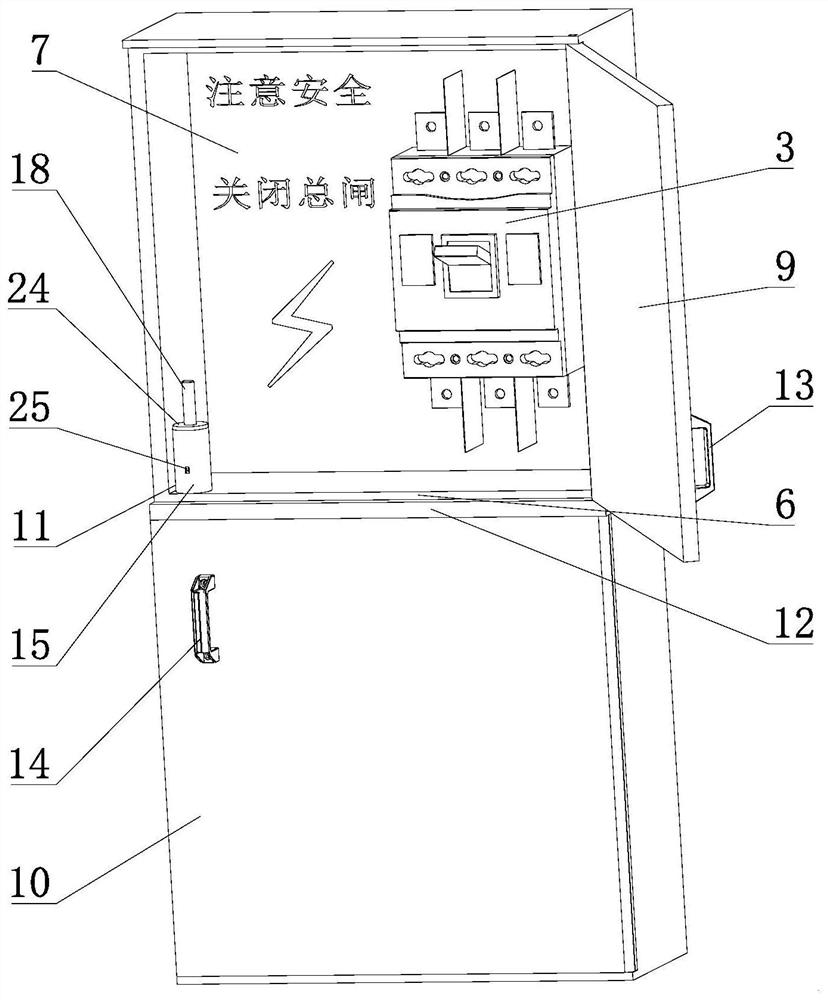

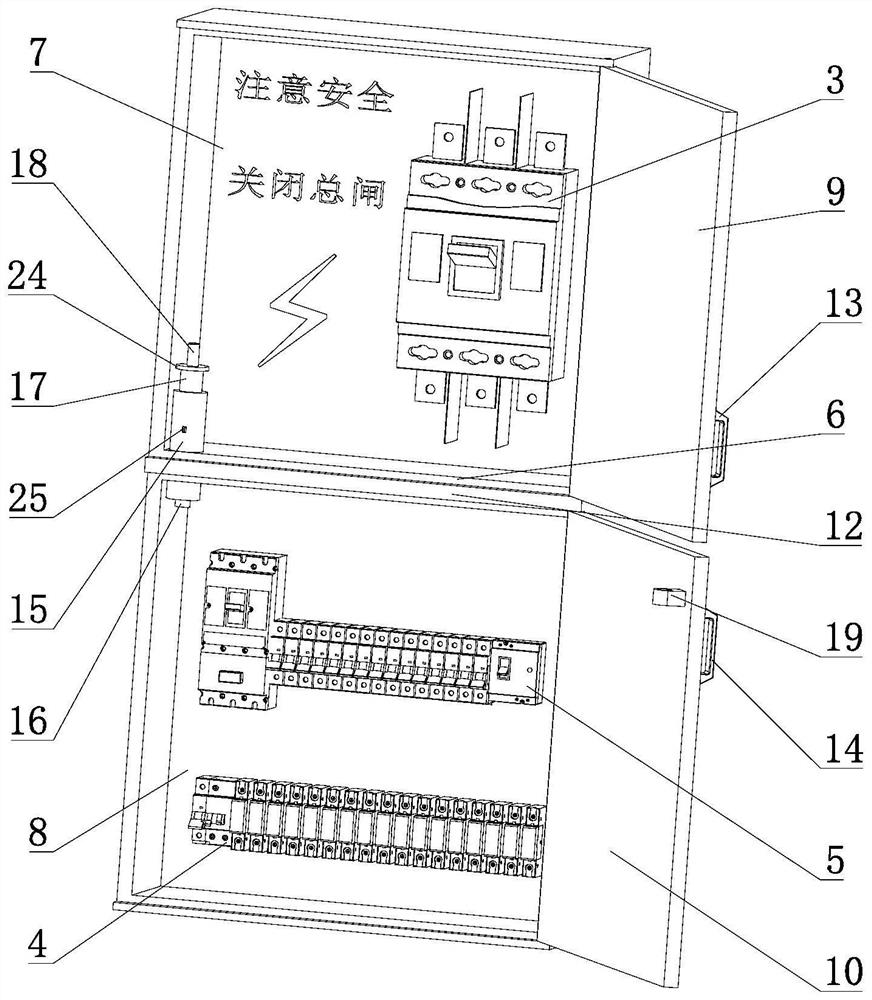

[0025] The structure of the power control cabinet of the present embodiment is as Figure 1 to Figure 7 Shown includes a cabinet 1 and a cabinet door 2, the cabinet 1 is used to place the main power switch 3, a number of circuit breakers 4 and a number of fuses 5, etc., the cabinet 1 is provided with a partition 6, and the partition 6 separates the cabinet 1. Divided into upper cabinet body 7 and lower cabinet body 8. Cabinet door 2 covers upper cabinet door 9 and lower cabinet door 10. Upper cabinet door 9 is hinged with upper cabinet body 7. Lower cabinet door 10 is hinged with lower cabinet body 8. Cooperate, the main switch 3 of the power supply is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com