Experimental device and method for simulating composite bottom wall effects of different structure types

A technology of compound diapirs and diapirs, which is applied to simulation devices, simulators, and teaching models of space navigation conditions. It can solve the problems of single function, simplicity, and single type, and achieve the effect of optimizing the type of experiment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing:

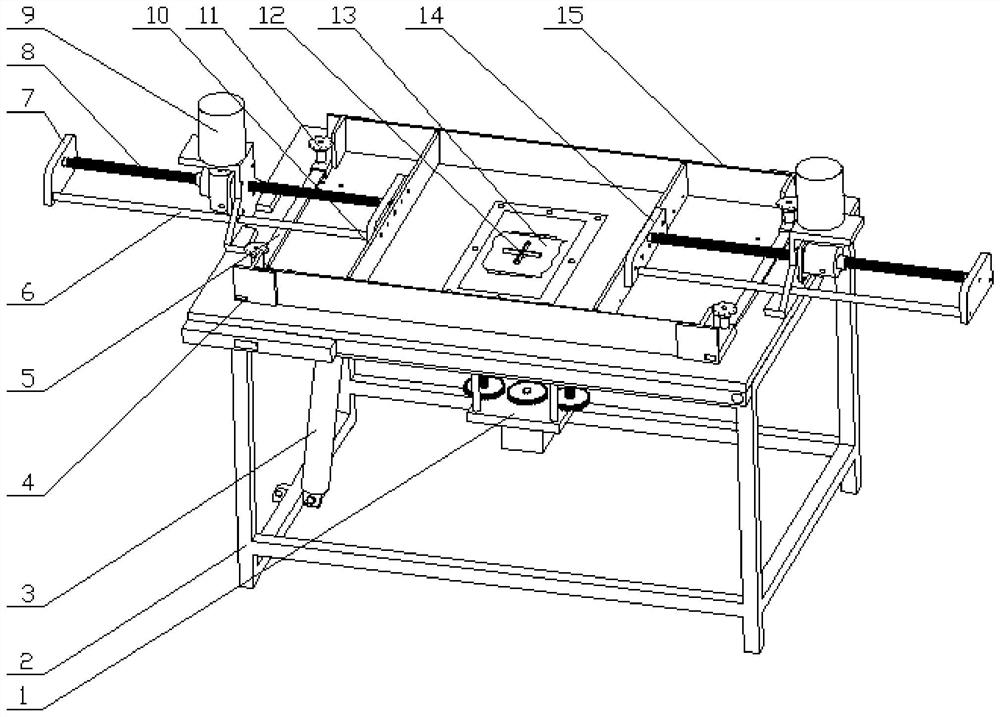

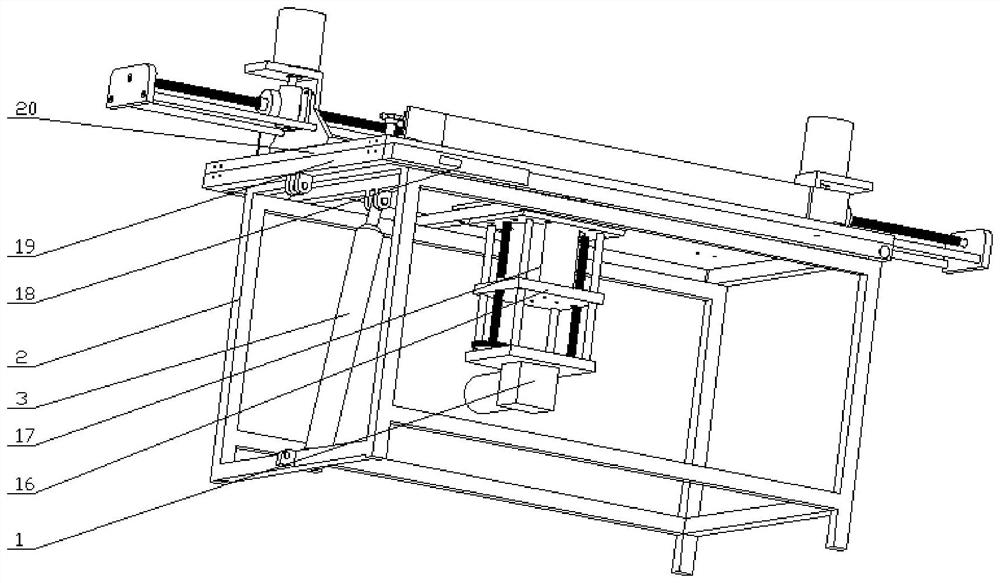

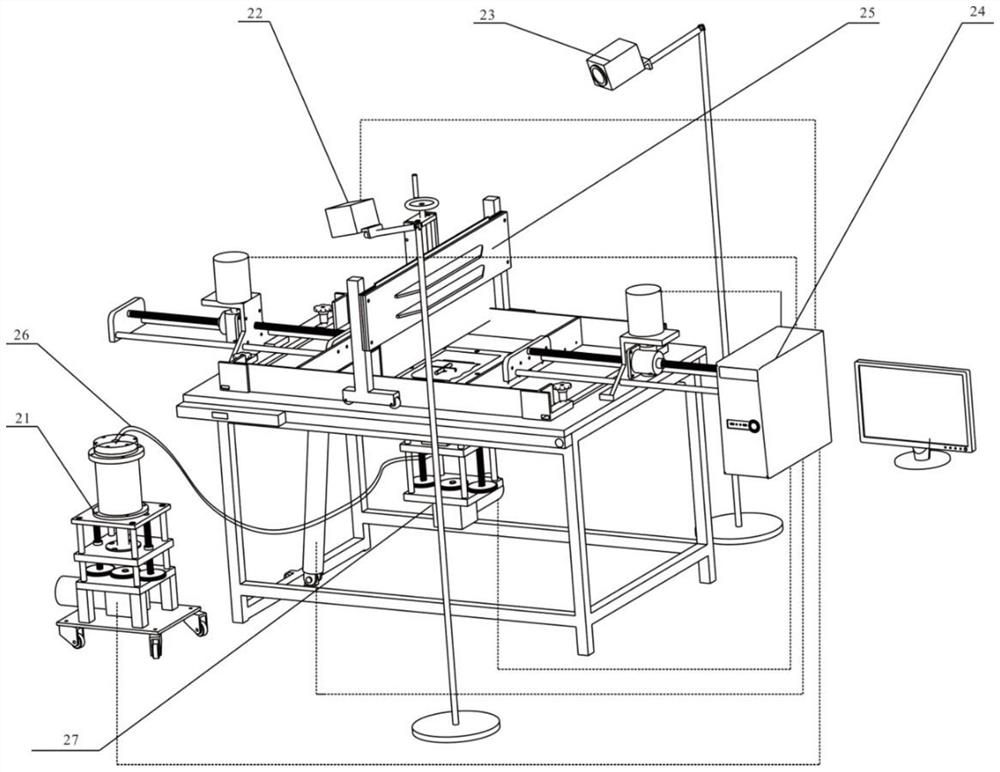

[0057] Such as Figure 1 to Figure 3 As shown, the sandbox physical simulation experiment device mainly includes five parts: platform skeleton system, experiment simulation system, drive system, experiment auxiliary system and control system.

[0058] The platform skeleton system is used to support the entire experimental equipment. The skeleton system mainly includes three parts: the test bench load-bearing bracket 2, the table panel 20 and the tilting support frame 19 of the table. Among them, the test bench load-bearing bracket 2 is 180cm long and 4 The length is 80cm, and four steel structures with a length of 80cm are composed together. The thickness of the table top 20 is 4cm. Because the experimental table is too thin, it will deform when it bears an excessive load, which will affect the experimental results. Therefore, it is necessary to design the experimental tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com