Mold core machining device for manufacturing light guide plate with novel structure

A new type of structure and processing device technology, applied in cleaning methods and utensils, removing smoke and dust, chemical instruments and methods, etc., can solve the problems of high cost of optical film composition, thick optical film thickness, destruction of total reflection of light, etc. Reduced wear, increased service life, faster and easier cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

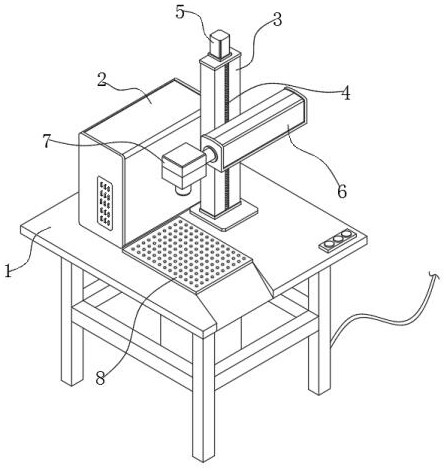

[0028] see Figure 1-7 , in an embodiment of the present invention, a mold core processing device for manufacturing a new structure light guide plate, which includes a processing table 1, a controller 2, a support arm 3 and a telescopic rod 6, wherein the processing table 1 is fixed with The controller 2 and the support arm 3 are provided with a vertically placed screw 4 for rotation in the support arm 3, and a screw nut seat is connected to the screw screw 4 in transmission, and the screw nut seat is connected with the telescopic rod 6. The telescopic rod 6 is horizontally arranged and attached to the outer surface of the support arm 3, and the screw 4 is also driven and rotated by the adjusting motor 5 fixed on the support arm 3;

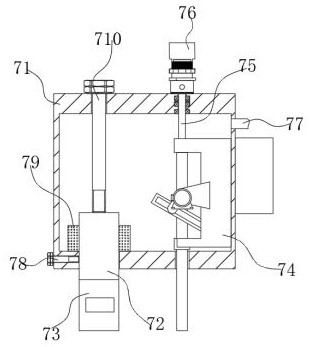

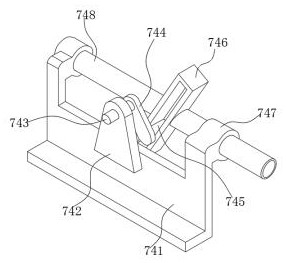

[0029] The telescopic end of the telescopic rod 6 is fixed with a processing head assembly 7, and the processing head assembly 7 can be driven by the telescopic rod 6 to move along the telescopic direction of the telescopic rod 6, so as to carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com