Treating cassette and image forming device

A technology for processing cartridges and components, which is applied in the fields of electrical recording technology using charge graphics, equipment for using electrical recording technology using charge graphics, and electrical recording technology. problems, to achieve the effect of improved dimensional accuracy, simple operation, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

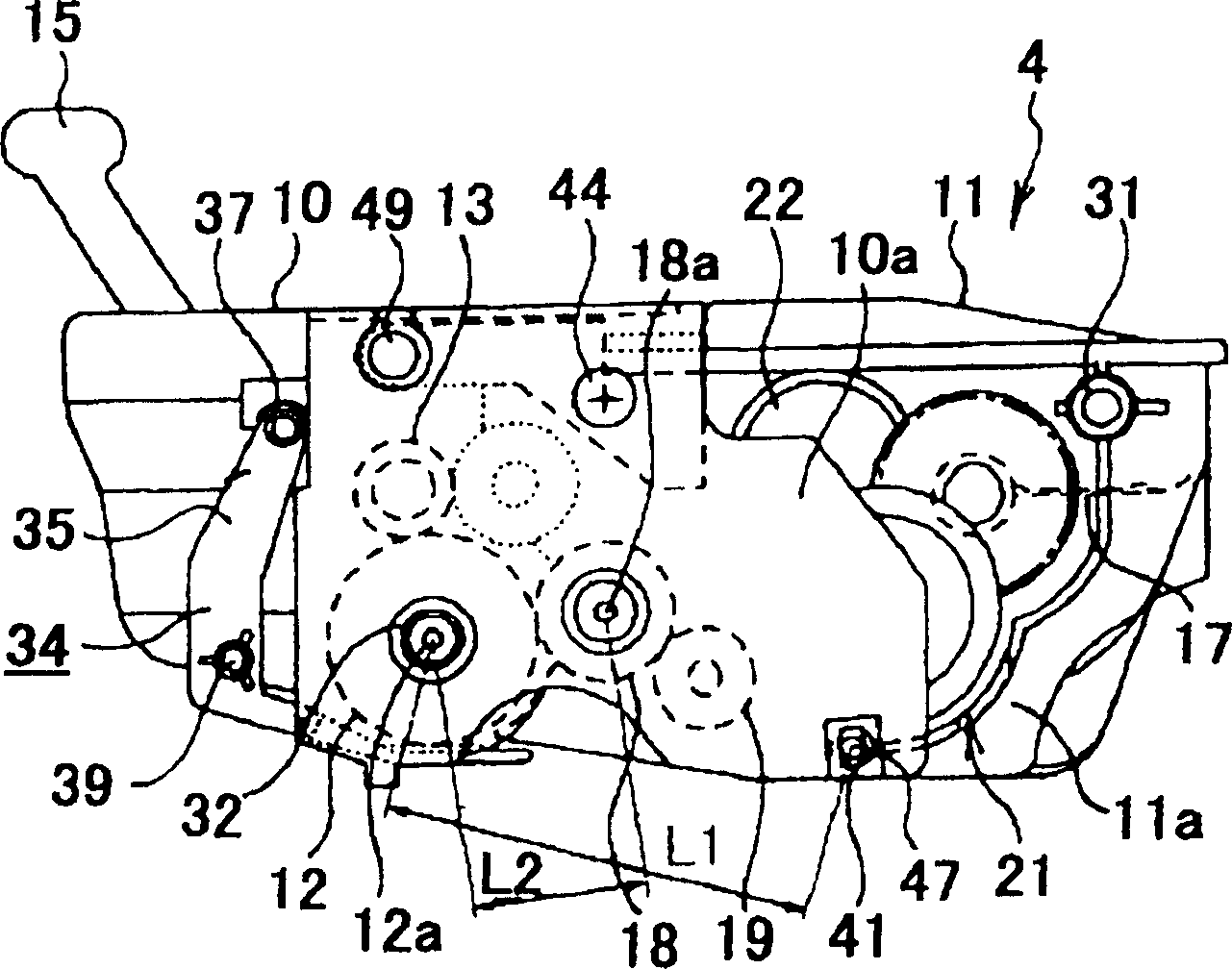

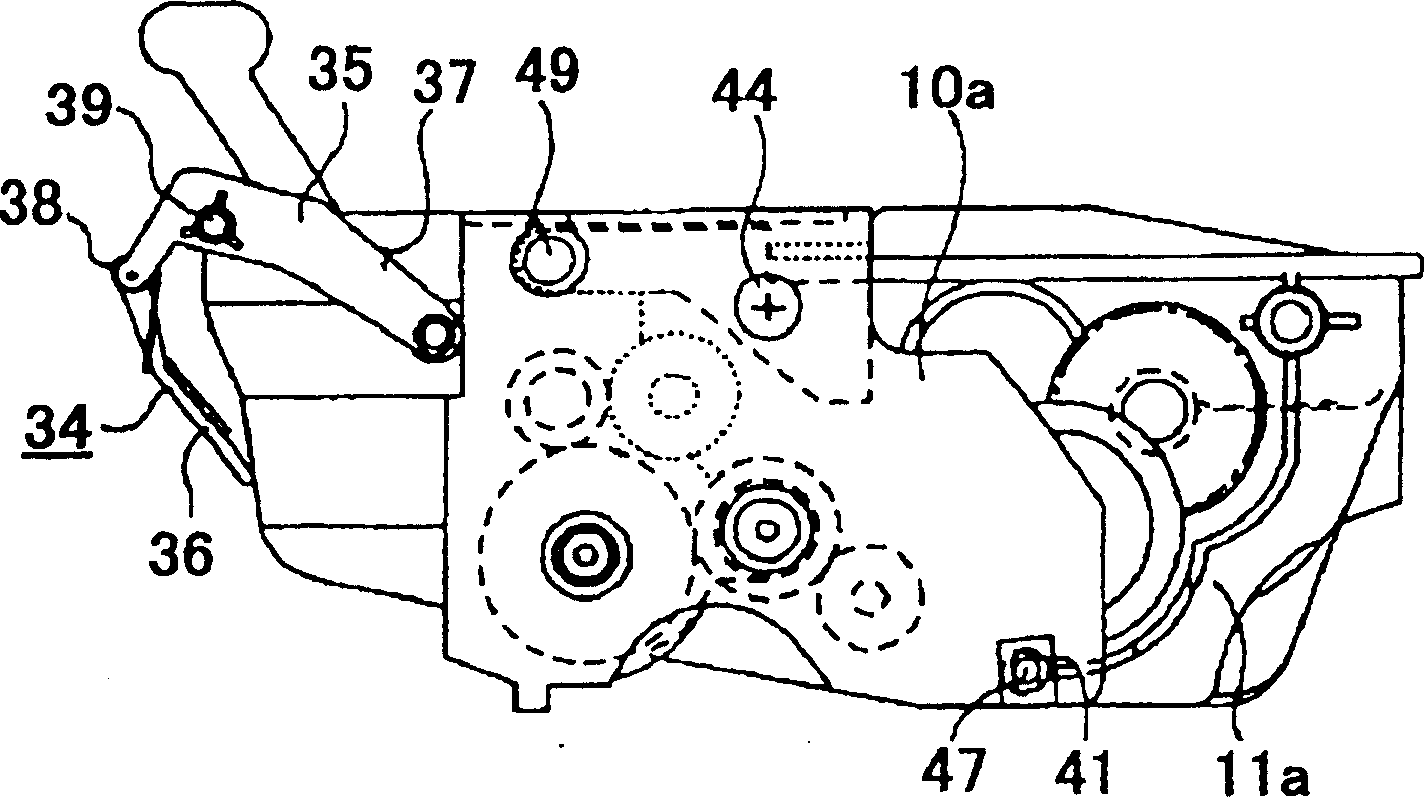

[0041] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

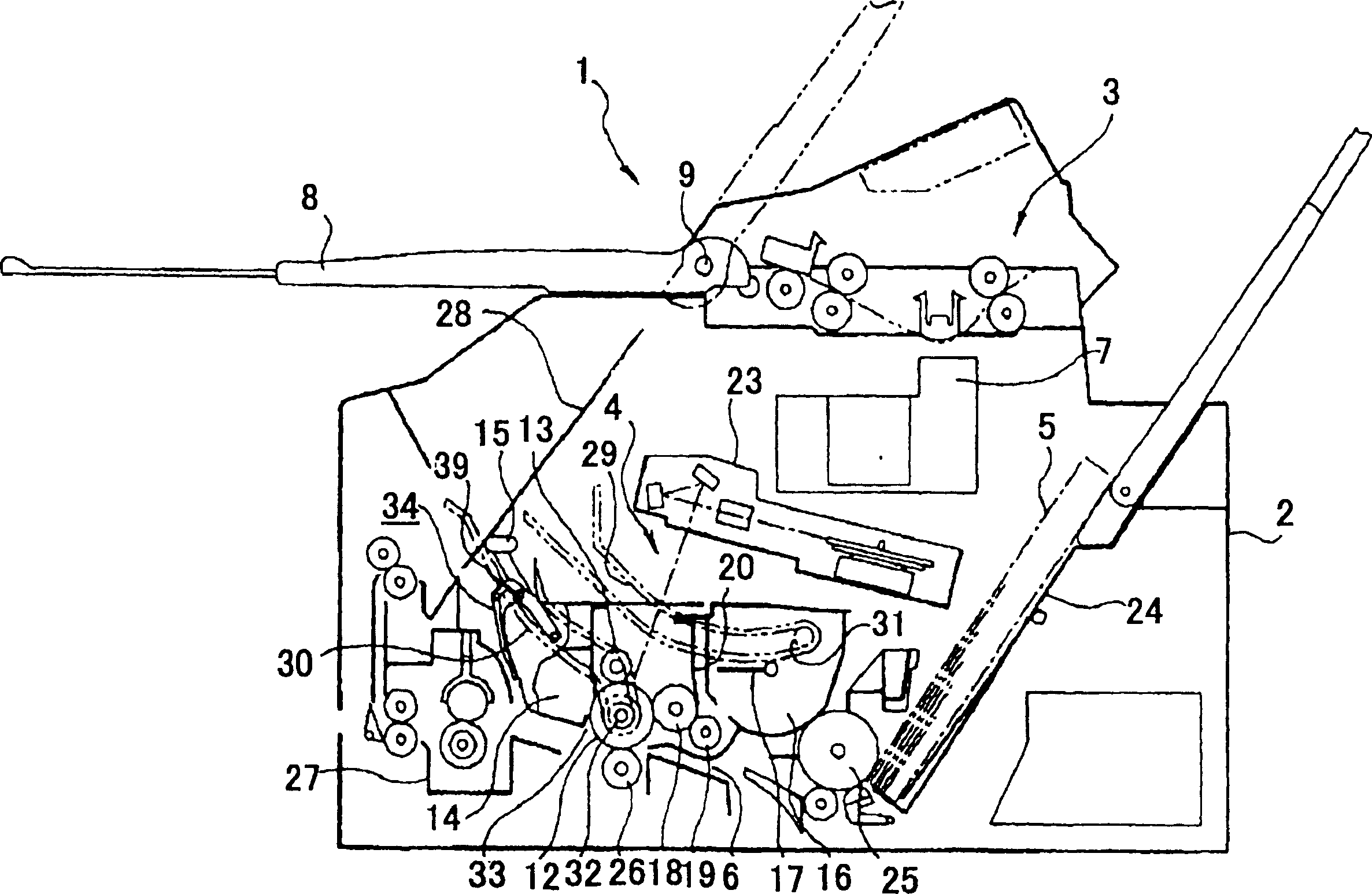

[0042] figure 1 It is a longitudinal sectional side view of the overall structure of the copier using the process cartridge of the present invention. An image reading device 3 is installed on the top of the body casing 2 of the copier 1 for reading images of original documents (not shown). A process cartridge 4 is detachably provided inside the casing 2, and a paper transport path 6 is formed below the process cartridge 4 for transporting transfer paper 5 as a recording medium.

[0043]The image reading device 3 includes an image reading unit 7 and a document tray 8. The image reading unit 7 feeds a document placed on the document tray 8 to a reading position for reading. As the center, it turns between the horizontal position represented by the solid line and the standing position represented by the double-dashed line, and the positions are fixed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com