Spraying system and agricultural plant protection machine

A spraying system and plant protection machine technology, applied in the field of agricultural plant protection spraying, can solve the problems of affecting spraying efficiency, inconvenient operation, speed of spraying system maintenance or replacement affecting efficiency, etc., to achieve the effect of ensuring spraying efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

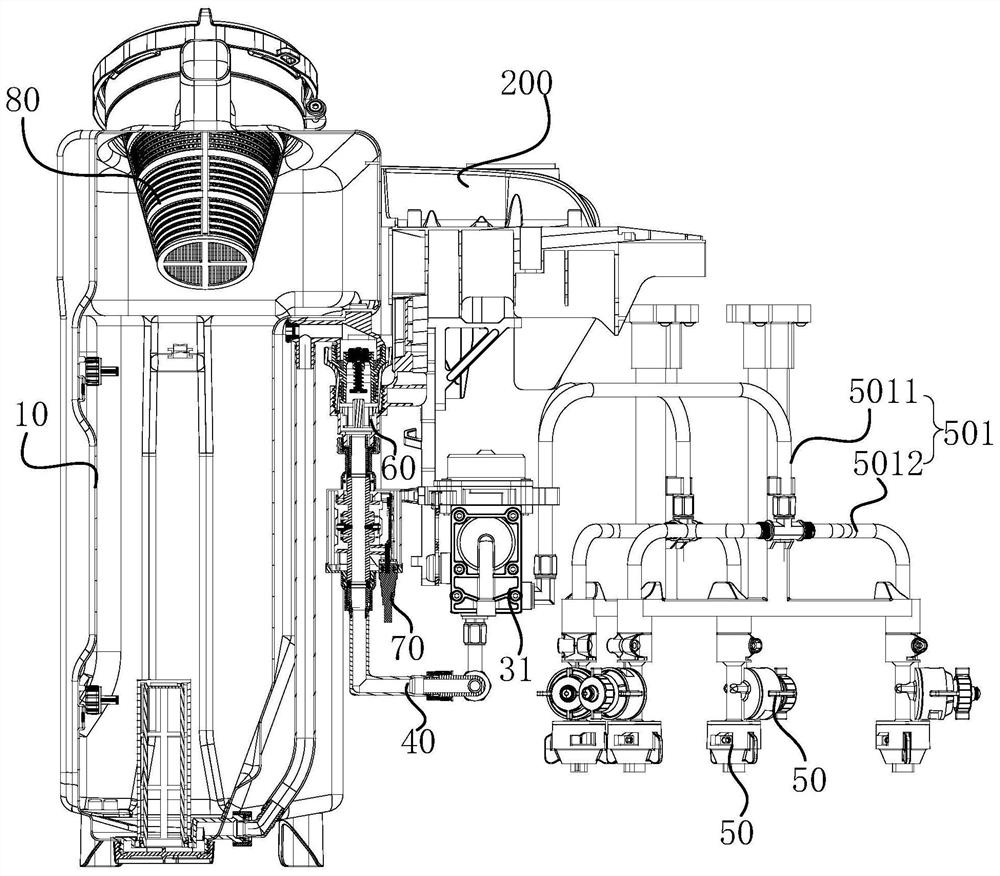

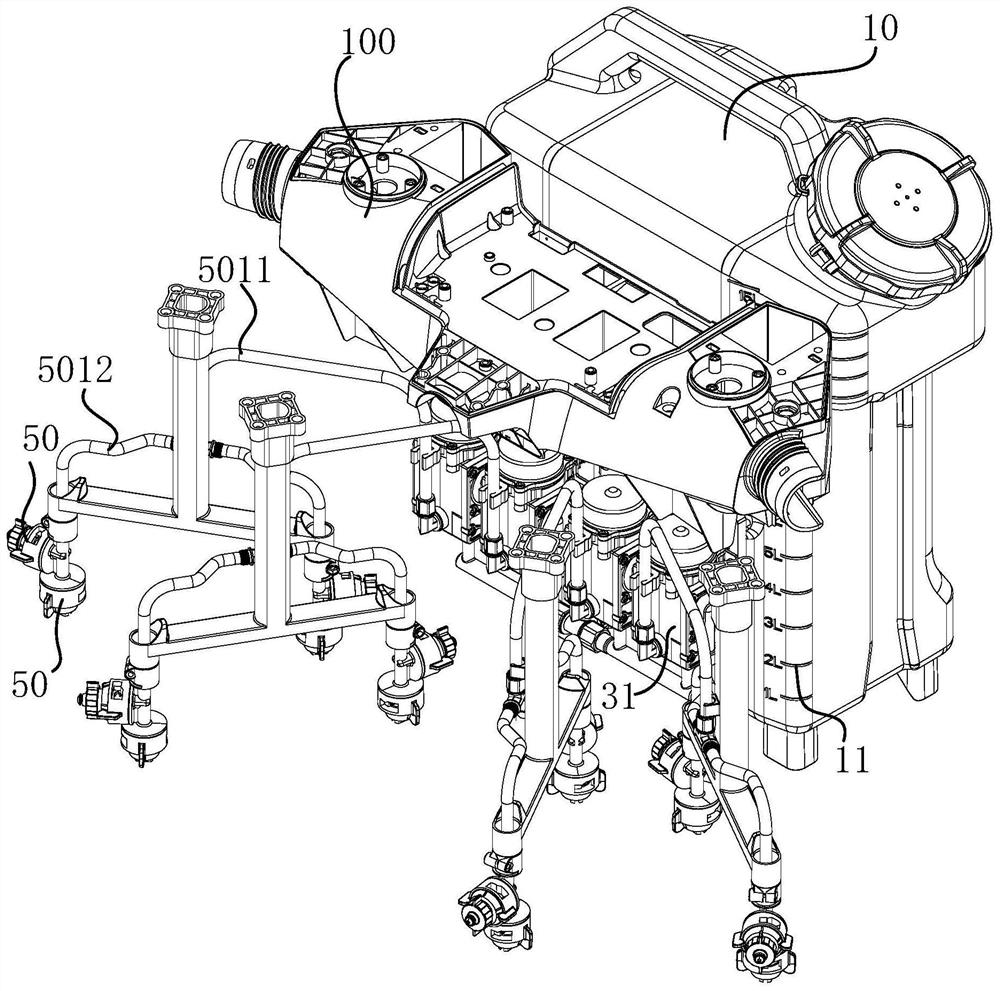

[0032] figure 1 The front view of the installation state of the sprinkler system and the rack provided by the embodiment of the present invention; figure 2 for figure 1 sectional view of image 3 The three-dimensional state diagram of the spraying system and the frame provided for the embodiment of the present invention; Figure 4 Schematic diagram of the installation of the pump set and the installation frame of the spraying system provided by the embodiment of the present invention Figure 1 ; Figure 5 Schematic diagram of the installation of the pump set and the installation frame of the spraying system provided by the embodiment of the present invention Figure II ; Figure 6 Schematic diagram of the installation of the pump set and the installation frame of the spraying system provided by the embodiment of the present invention Figure three . Please refer to Figure 1-Figure 6 , The sprinkler system 100 provided in this embodiment includes: a water tank 10 , an...

Embodiment 2

[0050] On the basis of the first embodiment, this embodiment further provides a specific installation method of the water pump 31, such as Figure 4 As shown, the first connecting portion may be the locking hole 21 , and the second connecting portion may be the locking member 311 matched with the locking hole 21 .

[0051] Specifically, the clamping hole 21 may be formed on the second mounting frame 20b, and the forming method of the clamping hole 21 may specifically be that a hole is formed on the second mounting frame 20b to form the clamping hole 21, or it may be formed on the second mounting frame 20b. Formed during integral molding, for example, the second mounting frame 20b is integrally injection molded. When designing the injection mold, a protrusion is provided at the position of the required forming hole 21. During the injection molding process, the injection material flows to the mold, and the protrusion blocks the injection molding. The material is injected to form...

Embodiment 3

[0056] This embodiment is based on the second embodiment, further, as Figure 4 and Figure 6 As shown, the clamping hole 21 may include a large hole portion 211 and a small hole portion 212 communicating with each other. The large hole portion 211 is used for inserting the holding member 311 , and the small hole portion 212 is used for mounting the holding member 311 . It can be understood that when the clamping hole 21 is formed on the second installation frame 20 b and the clamping member 311 is formed on the water pump 31 , the large hole portion 211 may be located above the small hole portion 212 . However, when the clamping hole 21 is formed on the water pump 31 and the clamping member 311 is formed on the second mounting bracket 20b, the small hole portion 212 is located above the large hole portion 211 .

[0057] Specifically, in this embodiment, since the large hole portion 211 does not need to cooperate with the holding member 311, it only needs to provide a space f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com