X-ray automatic detection device and method for detecting quality of transformer coil

An automatic detection device, transformer coil technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of consuming a lot of human resources, low efficiency of detection methods, complex detection process, etc., to improve labor intensity and shorten product production And iterative cycle, the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

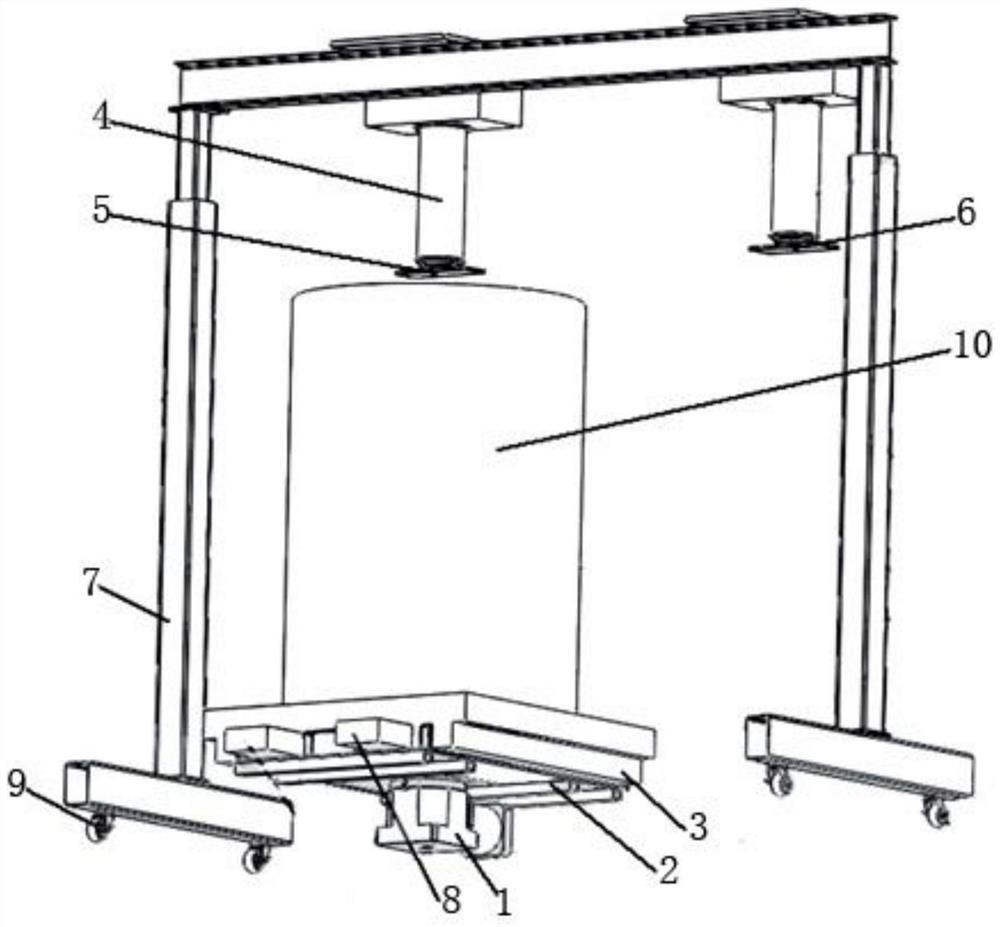

[0019] Such as figure 1 As shown, an X-ray automatic detection device for detecting the quality of transformer coils includes a rotating platform 1, a base 2, a coil tray 3, a bamboo-type electric hanger 4, an X-ray generator 5, an X-ray receiver 6 and Gantry 7, the rotating platform is fixed on the ground, the base is installed on the top of the rotating platform, the coil tray is installed on the top of the base, there are two bamboo-type electric hangers, which are respectively installed on the beam of the gantry, X-ray The generator and X-ray receiver are respectively fixed at the bottom of two bamboo-type electric hangers.

[0020] It also includes a PLC controller, which is respectively connected with the rotary platform, the bamboo-type electric hanger, the X-ray generator and the X-ray receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com