Engine timing measurement method and system and storage medium

A measurement system and measurement method technology, applied in the direction of engine testing, measuring devices, internal combustion engine testing, etc., can solve the problems that the timing relationship cannot be displayed intuitively, the measurement is difficult, time-consuming and labor-intensive, etc., to achieve convenient measurement and analysis , shorten the test time, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0037] Aiming at the fact that in the prior art, when measuring the engine timing, it cannot be displayed intuitively, the measurement is difficult, the error is large, the process is numerous, and time-consuming and labor-consuming, the present invention proposes a solution.

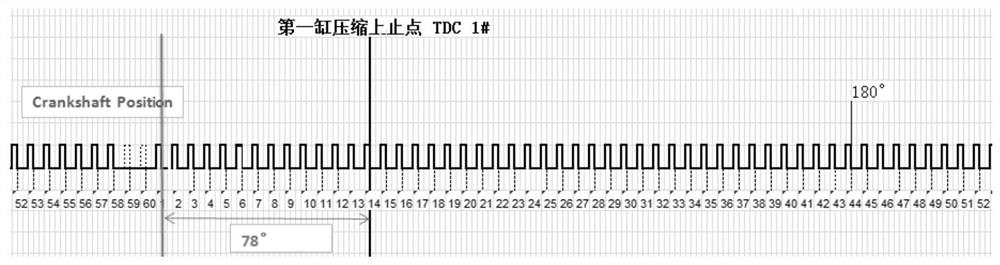

[0038] Specifically, the present invention proposes a method for measuring engine timing. The technical solution adopted in the method for measuring engine timing is mainly to use the lower computer combustion analyzer to collect crankshaft position signals and cylinder pressure signals in real time, and upload them to the upper computer for display. It is convenient for measurement analysis and comparative inspection; use the angle marker to measure the crankshaft angle, directly collect the signal of the engine crankshaft position sensor, disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com