Automobile front longitudinal beam detection table

A front longitudinal beam and testing table technology, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of reducing the efficiency of inspection and measurement, and the long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

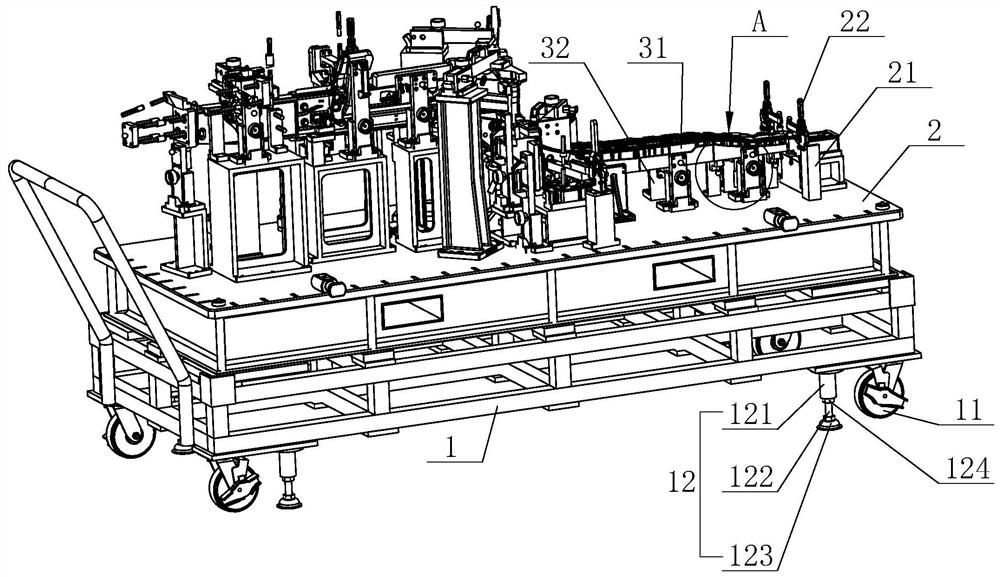

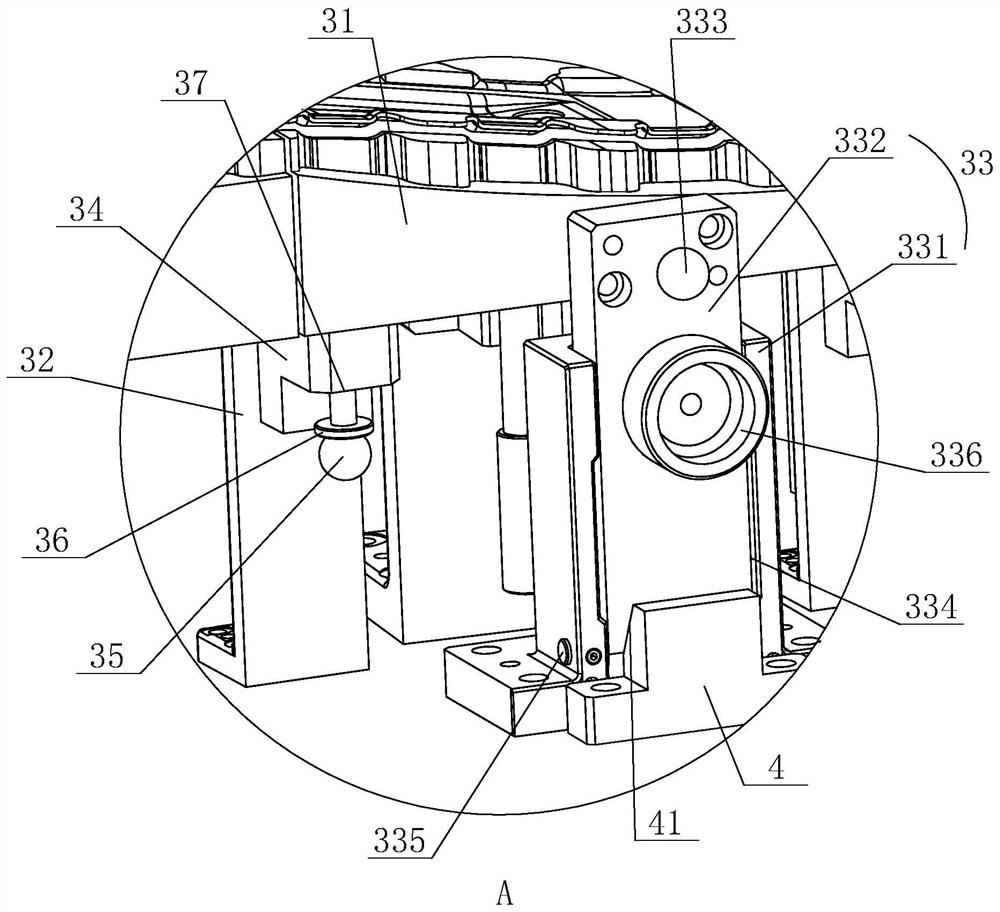

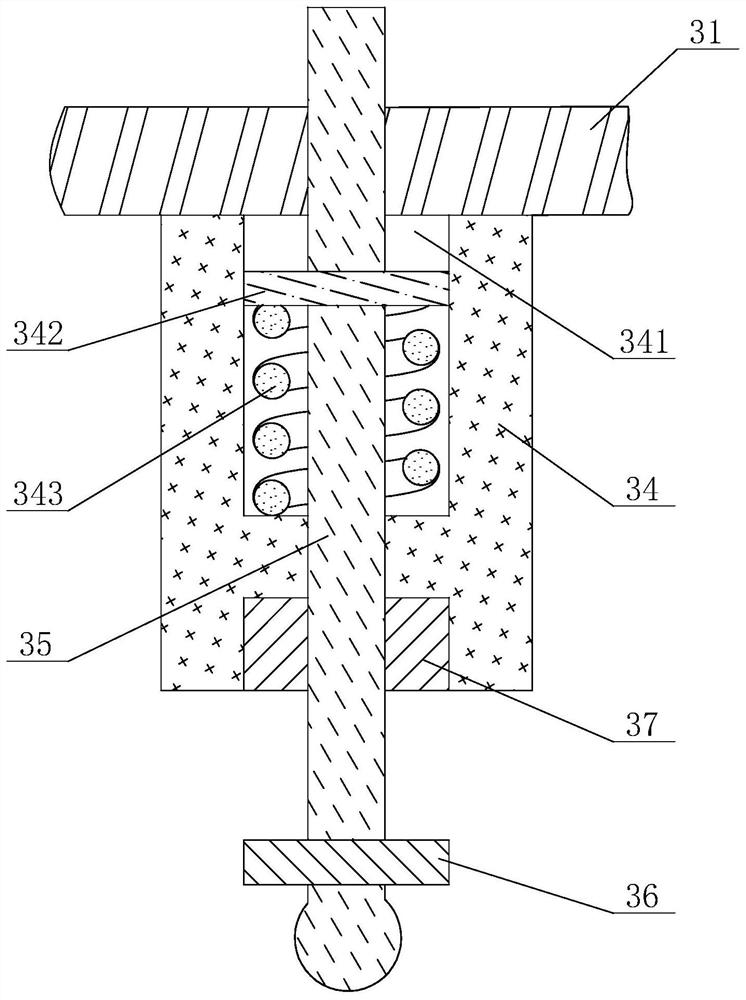

[0031] The following is attached Figure 1-3 The application is described in further detail.

[0032] The embodiment of the present application discloses an automobile front longitudinal beam inspection platform.

[0033] refer to figure 1 , the vehicle front longitudinal beam testing platform includes a checking tool car 1, a workbench 2 fixed on the checking tool car 1, and a detection component. A simulation block 31 , a plurality of support bases 32 and a positioning module 33 are installed on the front side beam of the vehicle. Two brackets 21 are detachably and fixedly connected on the workbench 2, and a pressure clamp 22 is connected with rotation on the bracket 21, and the head of the pressure clamp 22 is pressed on the front longitudinal beam under the detection state. After the front longitudinal beam is installed on the analog block 31, turn the press pliers 22 so that the head of the press clamp 22 is pressed on the front longitudinal beam, so that the front lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com