Disc scraper drying device

A technology of drying device and disc, which is applied in the direction of special treatment targets, water distribution pipes, chemical instruments and methods, etc., and can solve problems such as uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

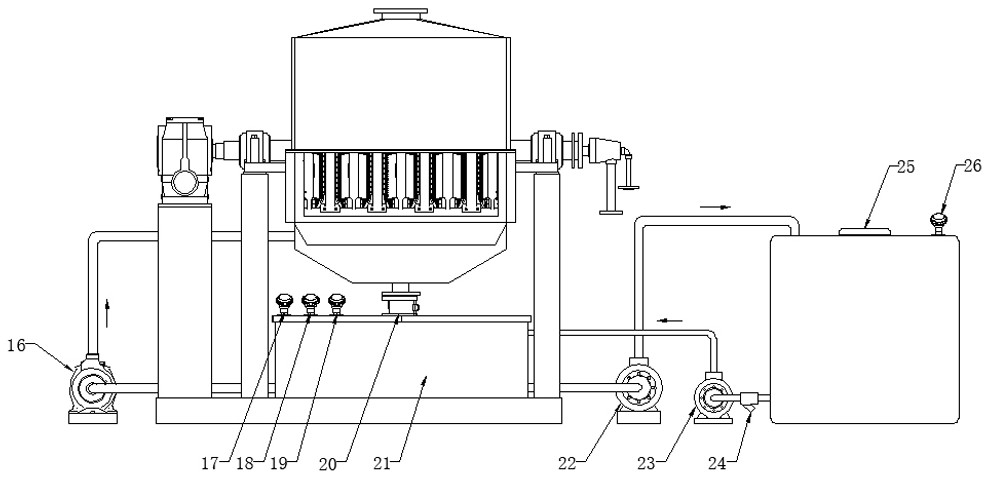

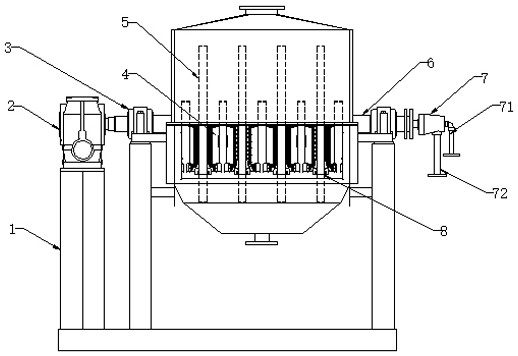

[0056] Embodiment: a disc scraper drying device, the reducer 2 is installed on the frame 1, several discs 5 are arranged side by side along the axial direction of the hollow rotating shaft 6, the discs are welded on the hollow rotating shaft 6, and the discs 5. The second steam channel and the first steam condensate discharge channel inside the hollow shaft 6 communicate with the first steam channel and the second steam condensate discharge channel respectively. One end of the hollow shaft 6 passes through the bearing 3 and the reducer 2 connection, the reducer 2 drives the hollow rotating shaft 6 to rotate with the disc 5, the other end of the hollow rotating shaft 6 is connected to the rotary joint 7, the first steam channel and the second steam condensate discharge channel in the hollow rotating shaft 6 are respectively connected to the rotary joint The steam inlet 72 of 7 is communicated with the steam condensed water outlet 71, and the disc 5 and the hollow rotating shaft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com