Slab transferring device

A technology of transfer device and sheet skin, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of reduced production efficiency, unsafety, suction cup damage, etc., and achieve the effect of ensuring the quality of finished products and reducing the impact of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The slab running device of the present embodiment, concrete technical scheme is as follows:

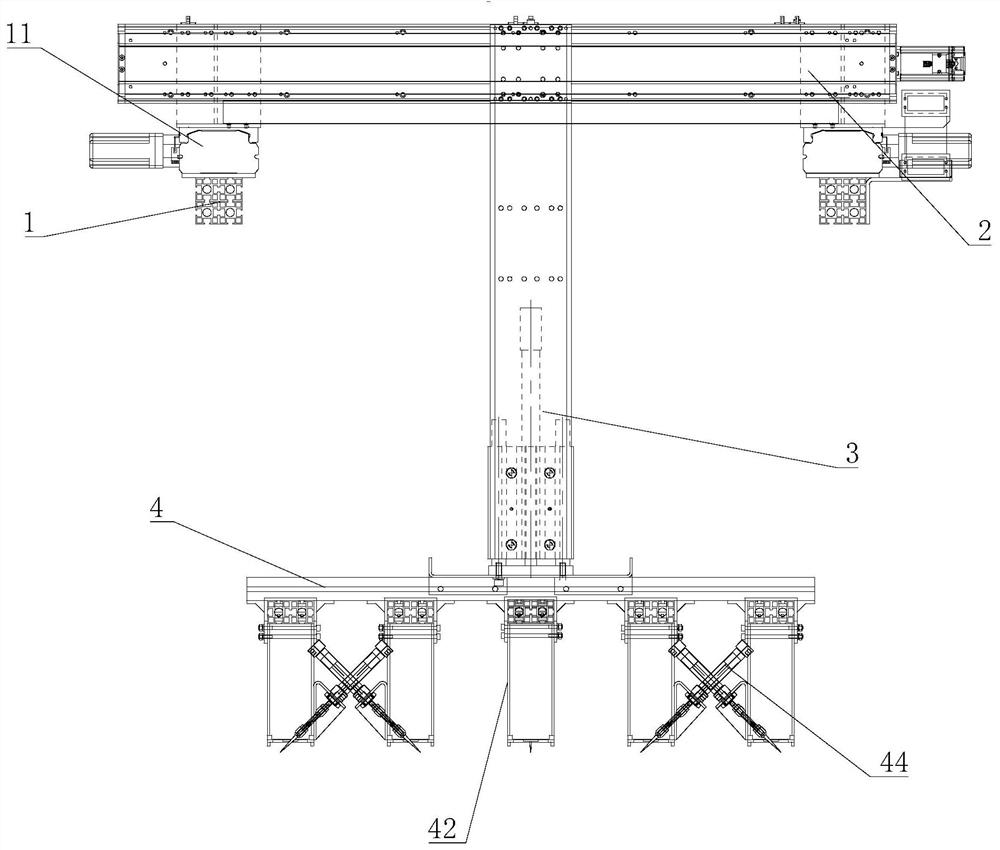

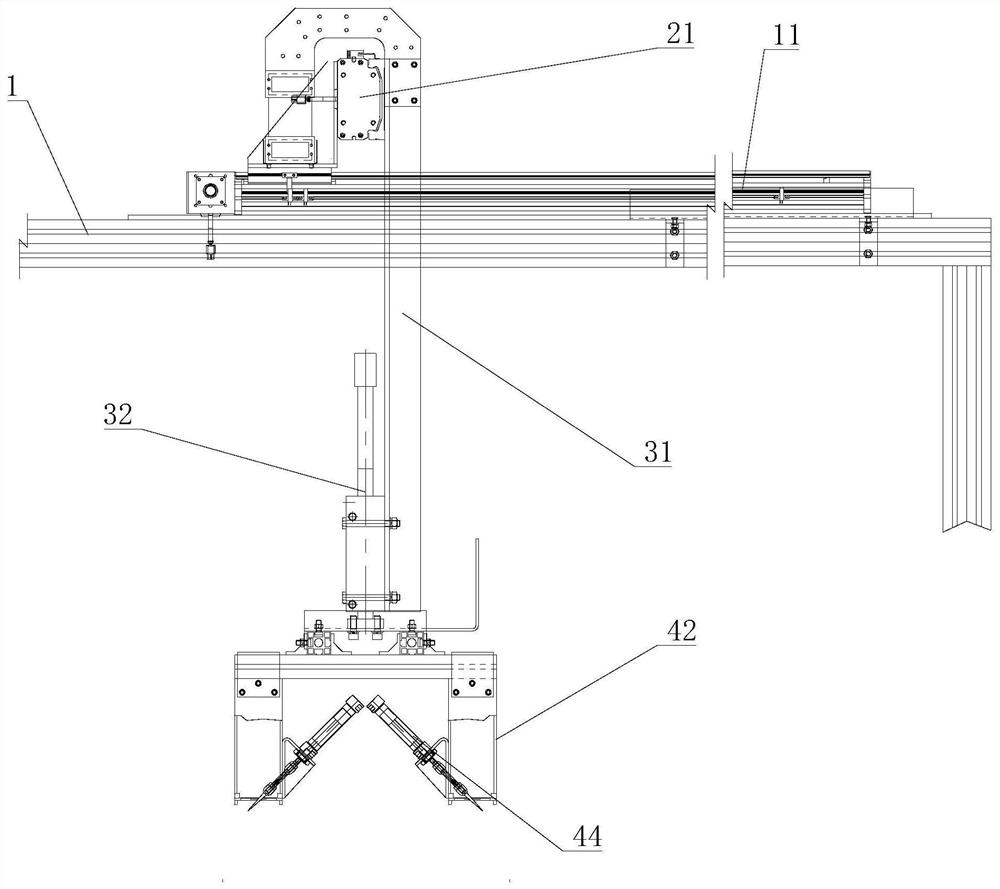

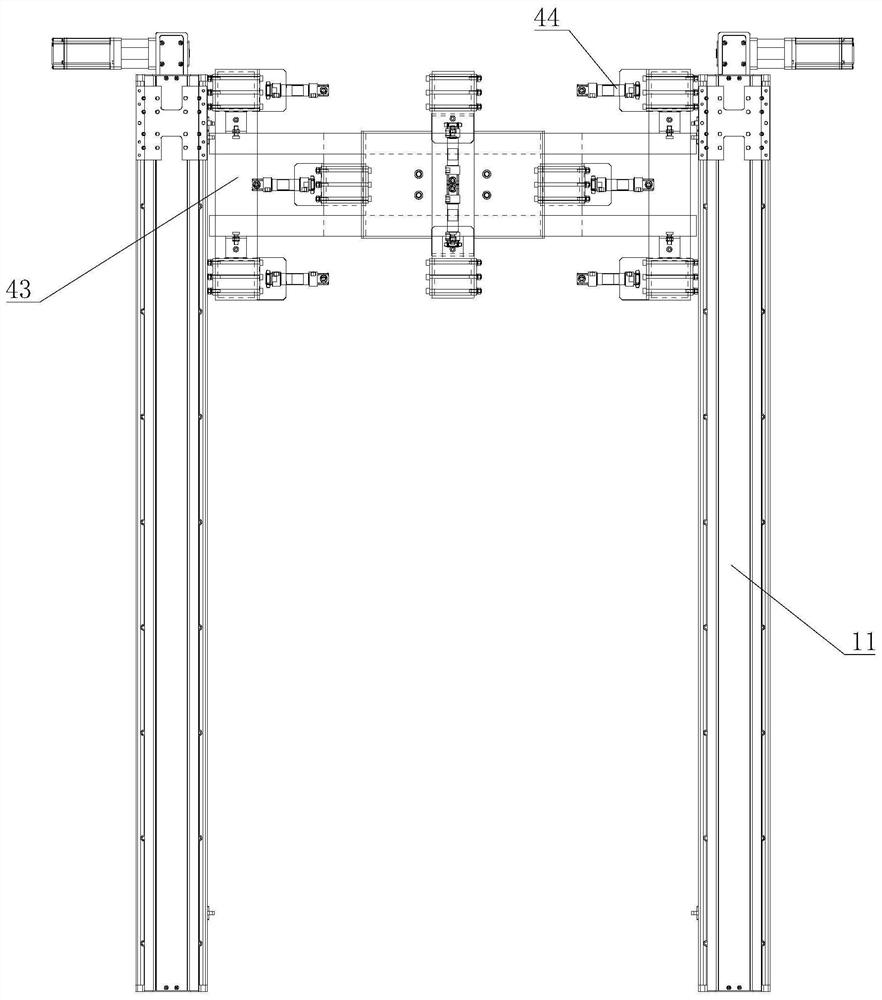

[0029] like Figure 1-3 As shown, the slab transfer device includes a bracket 1, a horizontal moving component 2 is slid on the bracket 1, and a lifting component 3 is slid on the horizontal moving component 2, and the sliding of the horizontal moving component 2 is vertical to the sliding direction of the lifting component 3 , the lifting component 3 is connected with the grabbing component 4, so that the lifting component 3, the lifting component 3 slides along the horizontal moving component 2, and the horizontal moving component 2 slides along the bracket 1 so as to realize the three-dimensional up and down, left and right and front and rear of the grabbing component 4 move. The grabbing assembly 4 includes a plurality of slab inserts 41 and a plurality of pressing sleeves 42 , and the slab inserts 41 are telescopically arranged in the pressing sleeves 42 . The pressure s...

Embodiment 2

[0036] The slab 5 operating device of the present embodiment, concrete technical scheme is as follows:

[0037] Plate skin 5 transfer device, such as Figure 6 As shown, it includes a bracket 1, a horizontal moving component 2 is slid on the bracket 1, a lifting component 3 is slid on the horizontal moving component 2, the sliding of the horizontal moving component 2 is vertical to the sliding direction of the lifting component 3, and the lifting component 3 is connected There is a grasping component 4, so through the lifting component 3, the lifting component 3 slides along the horizontal moving component 2, and the horizontal moving component 2 slides along the bracket 1 so as to realize the three-dimensional movement of the grasping component 4 up and down, left and right, and front and back. The grabbing assembly 4 includes a plurality of slab inserts 41 and a plurality of pressing sleeves 42 , and the slab inserts 41 are telescopically arranged in the pressing sleeves 42 ...

Embodiment 3

[0044] The slab 5 operating device of the present embodiment, concrete technical scheme is as follows:

[0045] Plate skin 5 transfer device, such as Figure 9 As shown, it includes a bracket 1, a horizontal moving component 2 is slid on the bracket 1, a lifting component 3 is slid on the horizontal moving component 2, the sliding of the horizontal moving component 2 is vertical to the sliding direction of the lifting component 3, and the lifting component 3 is connected There is a grasping component 4, so through the lifting component 3, the lifting component 3 slides along the horizontal moving component 2, and the horizontal moving component 2 slides along the bracket 1 so as to realize the three-dimensional movement of the grasping component 4 up and down, left and right, and front and back. The grabbing assembly 4 includes a plurality of slab inserts 41 and a plurality of pressing sleeves 42 , and the slab inserts 41 are telescopically arranged in the pressing sleeves 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com