A Magnetically Omnidirectional Transparent Material Conforming to the Uniaxial Perfectly Matched Layer Model

A technology for perfectly matching layers, transparent materials, applied in the field of magnetic transparent materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

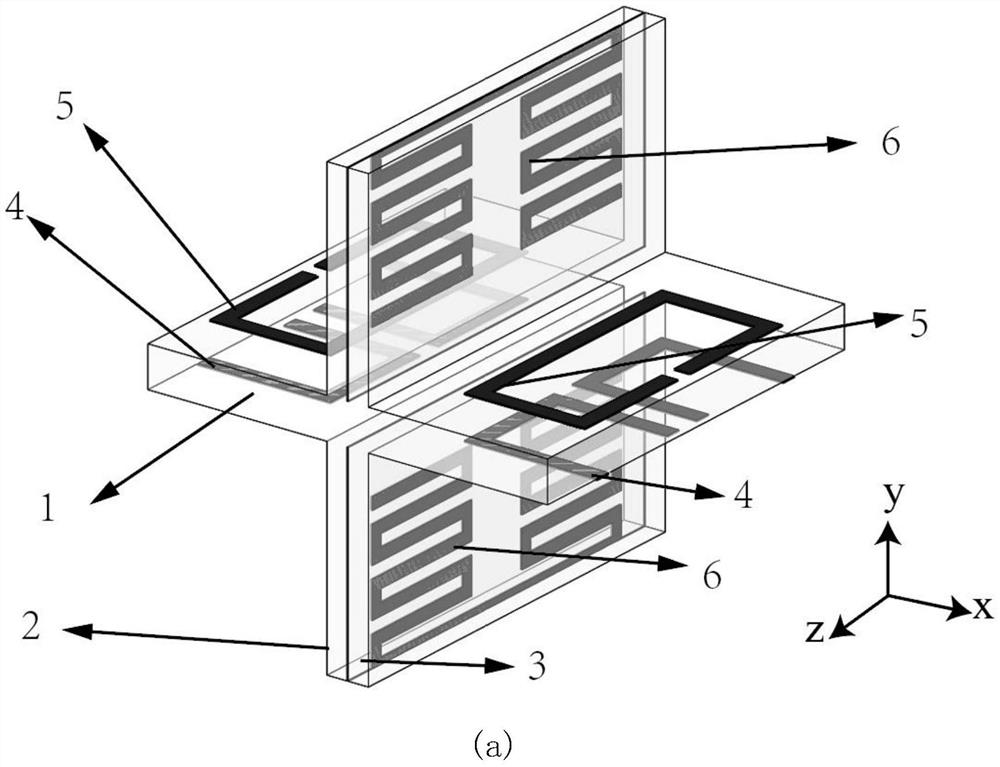

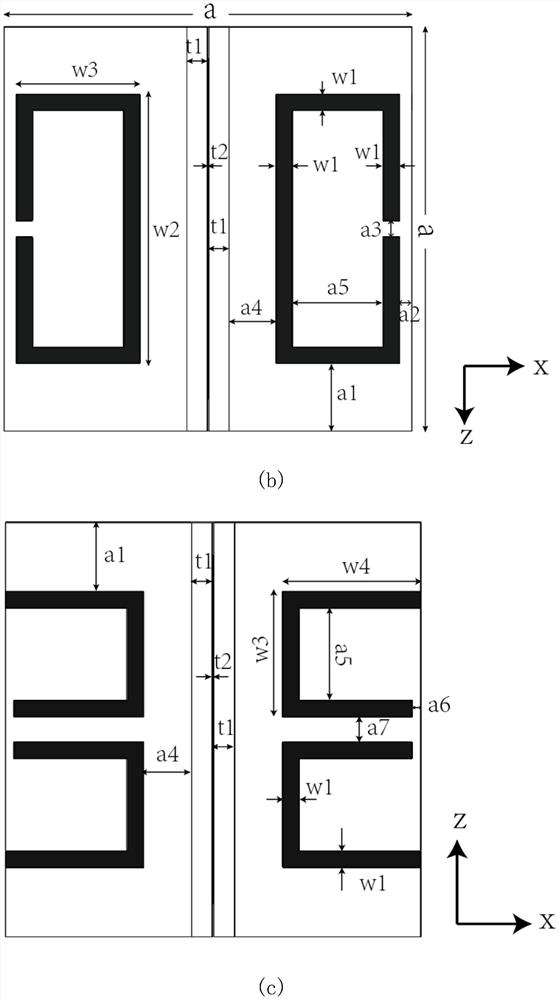

[0043] Such as figure 2 As shown, in the present invention, the cross-shaped sub-wavelength units with a length of 5 mm in the x-axis direction and a z-axis direction and a length of 5.6 mm in the y-axis direction are closely arranged along the x-axis direction and the y-axis direction to obtain perfect matching in all angles in free space transparent material. In this embodiment, the thickness of the first dielectric plate 1 is 0.5 mm, and the thicknesses of the second dielectric plate 2 and the third dielectric plate 3 are 0.25 mm respectively. The thickness of copper used for the first metal subwavelength open loop resonator 4 , the second metal subwavelength open loop resonator 5 and the metal U-shaped structure 6 is all 0.018mm. Such as figure 1 As shown, a=5mm, a1=0.8352mm, a2=0.15mm, a3=0.2mm, a4=0.8262mm, a5=1.1148mm, a6=0.1mm, a7=0.3mm, w1=0.2mm, w2=3.3296 mm, w3=1.5148mm, t1=0.25mm, t2=0.018mm, t3=0.5mm, p=5.6mm, l1=0.15mm, l2=0.075mm, l3=1.68mm, l4=0.15mm, l5=0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com