Automatic nut patting and harvesting device

A technology for harvesting devices and nuts, which is applied in the directions of harvesters, pickers, agricultural machinery and implements, etc., can solve the problems of inability to reduce the fatigue of manual harvesting, small working area, and high labor consumption, and achieves simple structure and increased flapping. Area, the effect of high implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

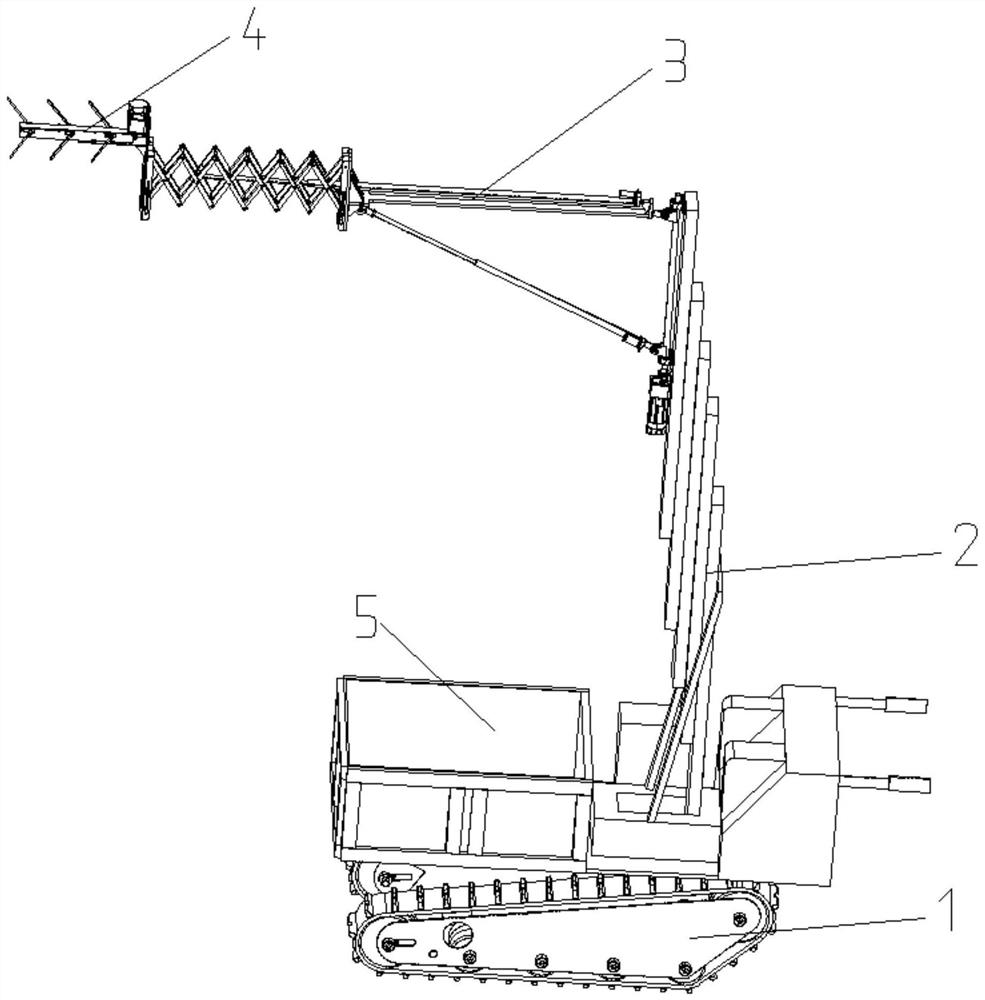

[0022] As an embodiment, the traveling mechanism 1 is a crawler belt traveling mechanism 1 .

[0023] As an embodiment, the lifting mechanism 2 is a hydraulic lifting platform.

[0024] As an embodiment, the traveling mechanism 1 is provided with a bucket 5 .

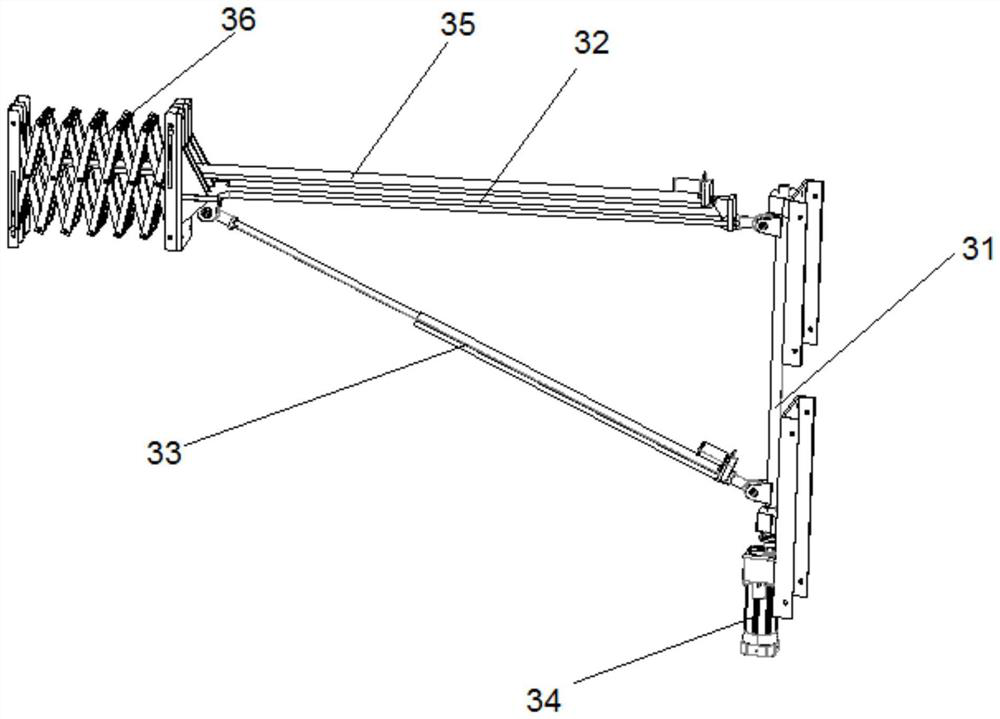

[0025] As an embodiment, the positioning mechanism 3 includes a vertical bar 31 connected end to end, a horizontal bar 32 and an oblique bar 33, the vertical bar 31 is fixed on a rotating motor 34, and the rotating motor 34 is fixed on the lifting mechanism 2 Above, the rotating motor 34 is used to drive the vertical rod 31 to rotate in the same plane. The oblique rod 33 includes an oblique drive motor and an oblique push rod. The oblique drive motor is hinged with the vertical rod 31. One end of the oblique push rod Fixed on the output shaft of the oblique drive motor, the other end of the oblique push rod is hinged with the vertical rod 31, one end of the horizontal rod 32 is hinged with the vertical rod 31, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com