Ground assembly type wiring duct mounting structure

An installation structure and assembly technology, applied in the direction of cable installation and cable installation in ground conduits, can solve problems such as inconvenient cable troubleshooting, and achieve the effect of easy cable troubleshooting, easy troubleshooting, and beautiful structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

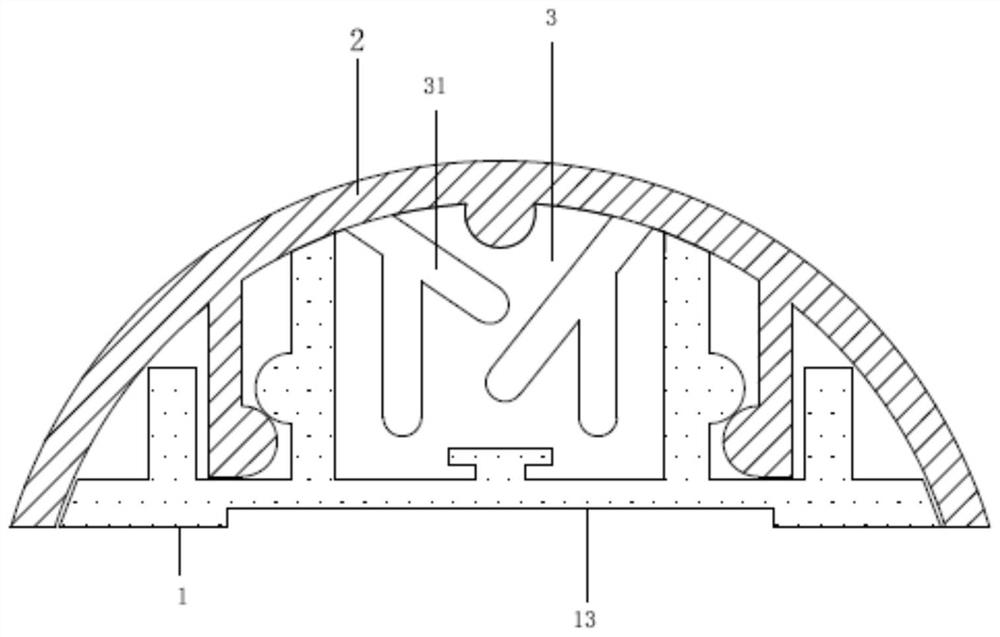

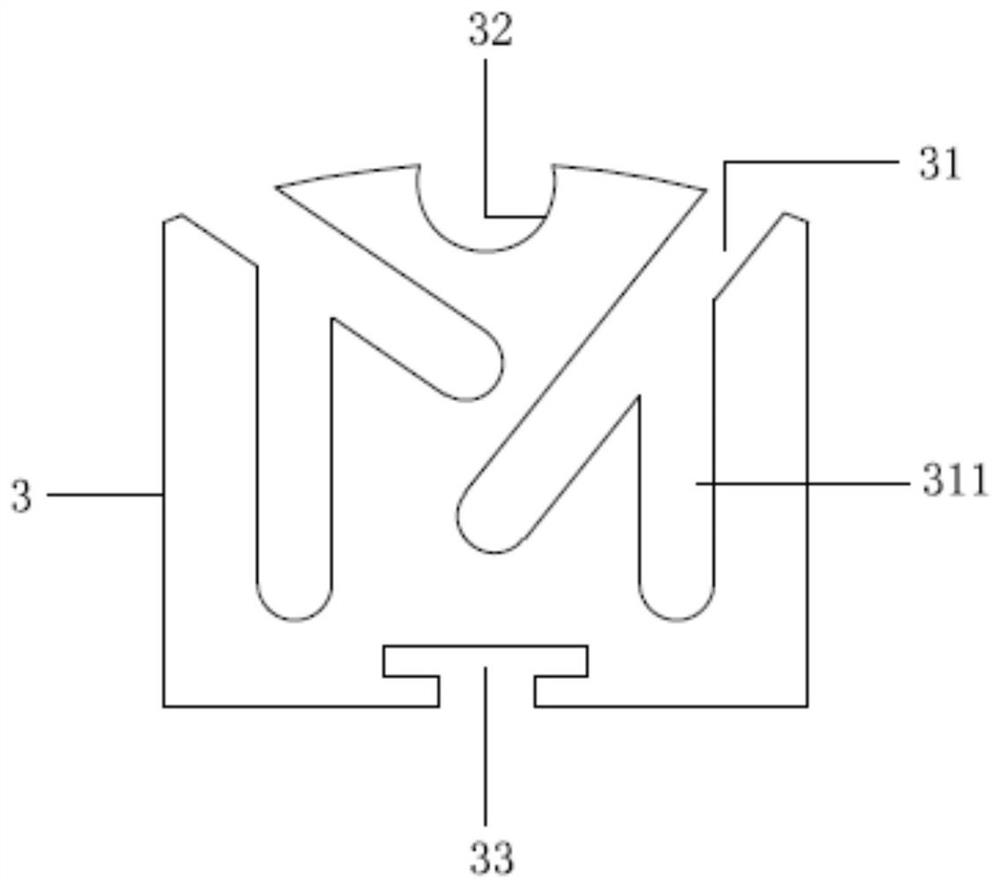

[0021] see Figure 1 to Figure 3 , the figure shows a ground-mounted wiring trough installation structure provided by Embodiment 1 of the present invention, including a base 1 and a cover plate 2, the base 1 is fixedly installed on the ground, and the base 1 is provided with a U-shaped wiring trough 11. The U-shaped threading groove 11 is provided with a plurality of partitions 3 arranged in parallel along its own length direction. The partitions 3 are provided with a plurality of notches 31 extending from the top edge to the inside, and the two ends of the cover plate 2 are arranged symmetrically. The buckle 21, the buckle 21 is fastened in the buckle groove 12 on the base.

[0022] Specifically, see Figure 1 to Figure 3 , the bottom surface of the base 1 is provided with a second groove 13 .

[0023] Specifically, see Figure 1 to Figure 3 , The partition 3 is detachably installed on the base 1 .

[0024] Specifically, see Figure 1 to Figure 3 The base 1 is provided w...

Embodiment 2

[0028] see Figure 1 to Figure 3 , the figure shows a ground-mounted wiring trough installation structure provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: cover plate 2 Ribs 22 arranged along the lengthwise direction are arranged on the inner side, and first grooves 32 corresponding to the ribs 22 are arranged on the separator 3 .

[0029] The inner side of the cover is provided with ribs to enhance its structural strength. The ribs are snapped into the first groove on the partition, on the one hand to ensure the assembly accuracy of the wiring trough, and on the other hand to use the partition to provide support for the cover .

Embodiment 3

[0031] see Figure 1 to Figure 3 , the figure shows a ground-mounted wiring trough installation structure provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the notch 31 is inclined Setting; the notch 31 includes at least one branch notch 311 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com