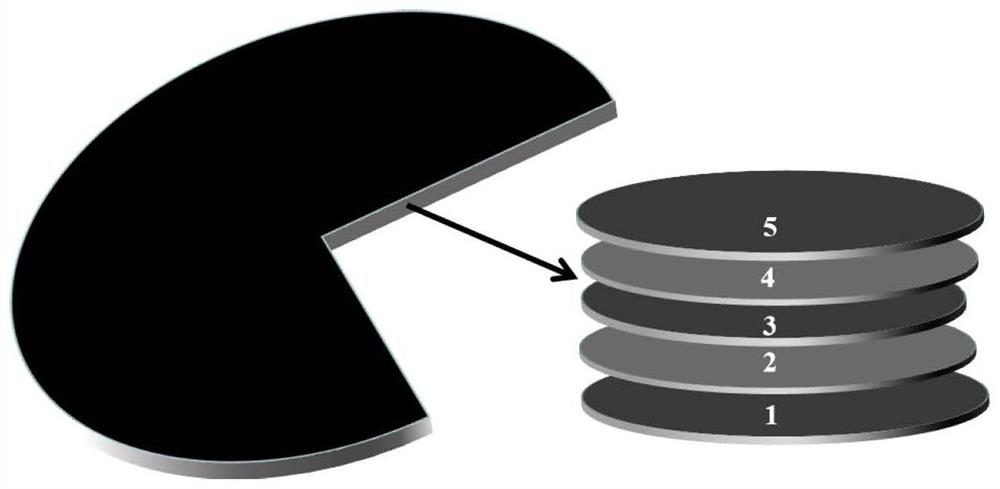

Zinc-cobalt bimetallic oxide sandwich structure flexible film electrode and preparation method thereof

A double metal oxide, flexible film technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of narrow applicable voltage window, low energy density of supercapacitors, poor cycle stability, etc., to achieve high voltage range, good electrolyte absorption, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

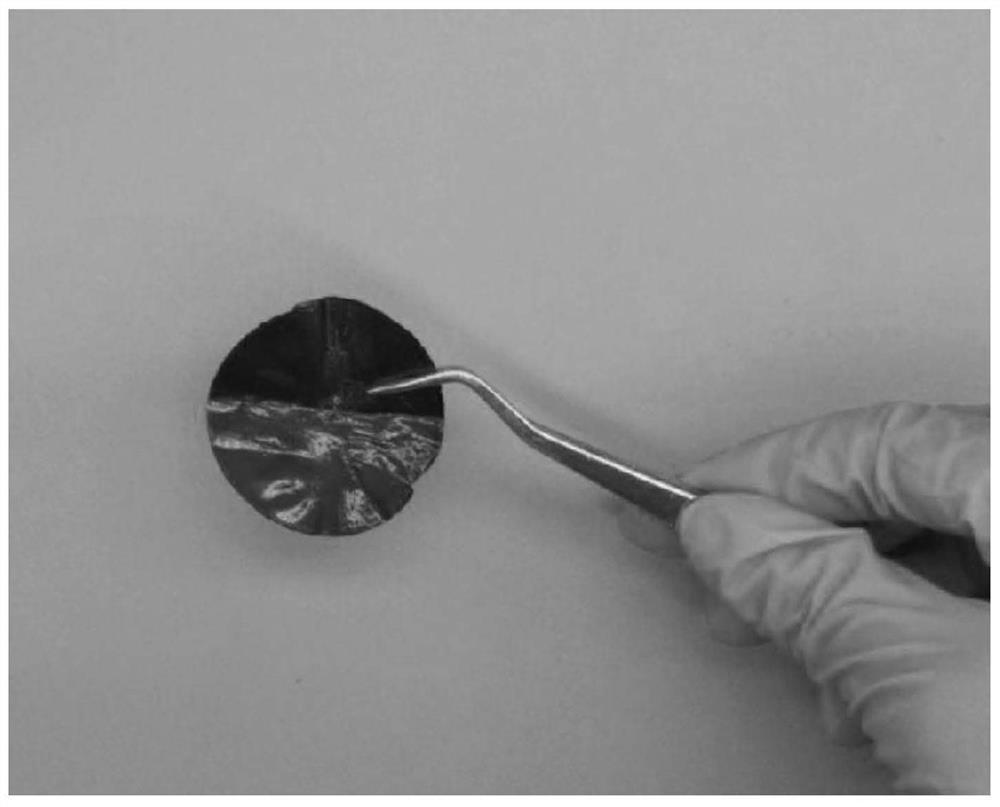

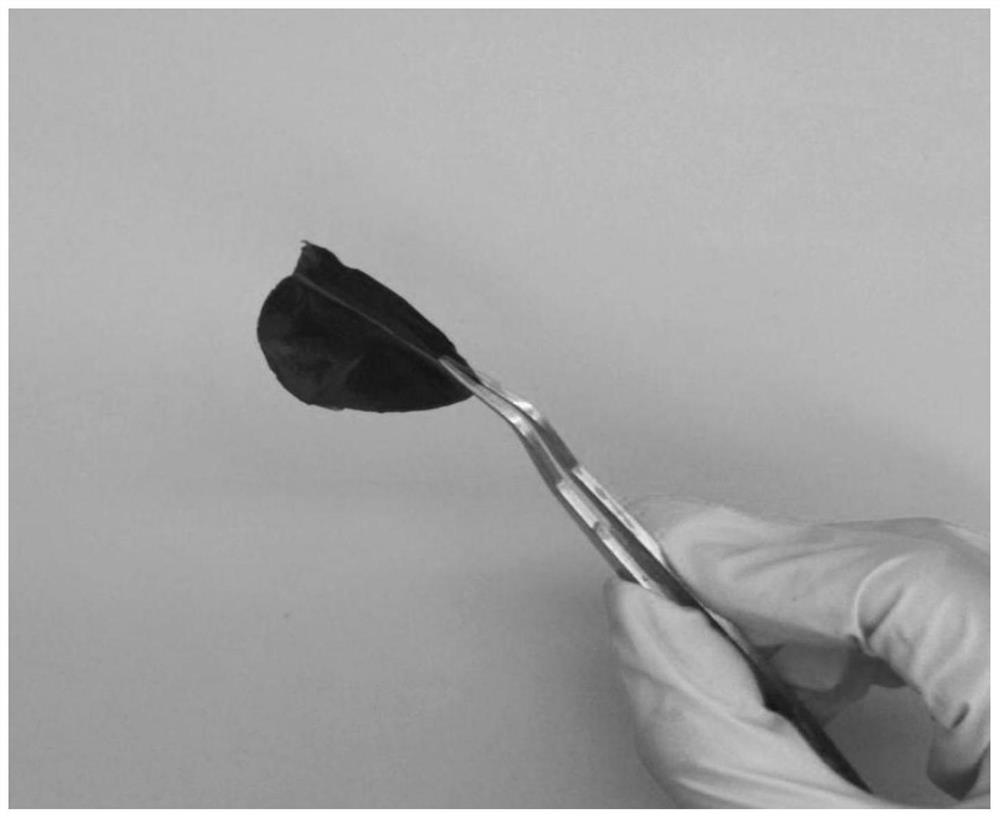

Method used

Image

Examples

Embodiment 1

[0038] S1. Disperse 7g of cellulose nanofibril aqueous solution and 0.07g of multi-walled carbon nanotubes in 39.58mL of deionized water with a mass fraction of 1wt%, ultrasonically disperse for 30min (power 600W), and magnetically stir for 30min (700r / min), to obtain Uniform 0.3wt% cellulose nanofibril-multi-walled carbon nanotube dispersion;

[0039]S2. Dissolve 0.328g of 2-methylimidazole in 25mL of methanol, and record it as solution A, and stir magnetically for 10min (600r / min); dissolve 0.323g of cobalt nitrate hexahydrate and 0.06g of zinc nitrate hexahydrate in 25mL of methanol, record For solution B, after magnetically stirring for 10min (600r / min), mix A and B solutions, magnetically stir for 10min (600r / min), place at room temperature for 24h, centrifuge (6500r / min) for 8min to obtain a purple precipitate, and use anhydrous Washing with ethanol three times, and vacuum-drying at 80° C. to obtain a zinc-cobalt bimetallic organic framework composite. The zinc-cobalt d...

Embodiment 2

[0047] S1. Disperse 13g of cellulose nanofibril aqueous solution and 0.13g of multi-walled carbon nanotubes in 38.87mL of deionized water with a mass fraction of 1wt%, ultrasonically disperse for 30min (power 600W), and magnetically stir for 30min (700r / min), to obtain Uniform 0.5wt% cellulose nanofibril-multi-walled carbon nanotube dispersion;

[0048] S2. Dissolve 0.328g of 2-methylimidazole in 25mL of methanol, and record it as solution A, and stir magnetically for 10min (600r / min); dissolve 0.323g of cobalt nitrate hexahydrate and 0.06g of zinc nitrate hexahydrate in 25mL of methanol, record For solution B, after magnetic stirring for 10 minutes (600r / min), mix the two solutions of A and B, magnetic stirring for 10 minutes (600r / min), and place at room temperature for 24 hours. Centrifuge (6500r / min) for 8min to obtain a purple precipitate, wash with absolute ethanol three times, and vacuum-dry at 80°C to obtain a zinc-cobalt bimetallic organic framework complex. The zinc...

Embodiment 3

[0056] S1. Disperse 7g of cellulose nanofibril aqueous solution and 0.07g of multi-walled carbon nanotubes in 39.58mL of deionized water with a mass fraction of 1wt%, ultrasonically disperse for 30min (power 600W), and magnetically stir for 30min (700r / min), to obtain Uniform 0.3wt% cellulose nanofibril-multi-walled carbon nanotube dispersion;

[0057] S2. Dissolve 0.328g of 2-methylimidazole in 25mL of methanol, and record it as solution A, and stir magnetically for 10min (600r / min); dissolve 0.323g of cobalt nitrate hexahydrate and 0.06g of zinc nitrate hexahydrate in 25mL of methanol, record For solution B, after magnetic stirring for 10 minutes (600r / min), mix the two solutions of A and B, magnetic stirring for 10 minutes (600r / min), and place at room temperature for 24 hours. Centrifuge (6500r / min) for 8min to obtain a purple precipitate, wash with absolute ethanol three times, and vacuum-dry at 80°C to obtain a zinc-cobalt bimetallic organic framework complex. The zinc-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com