Annular self-filling sand control screen

A technology for sand control screens and sand layers, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve the problems of complex construction process, high cost, and poor sand control effect, and achieve high bond strength and low cost. Low, the effect of preventing well wall collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

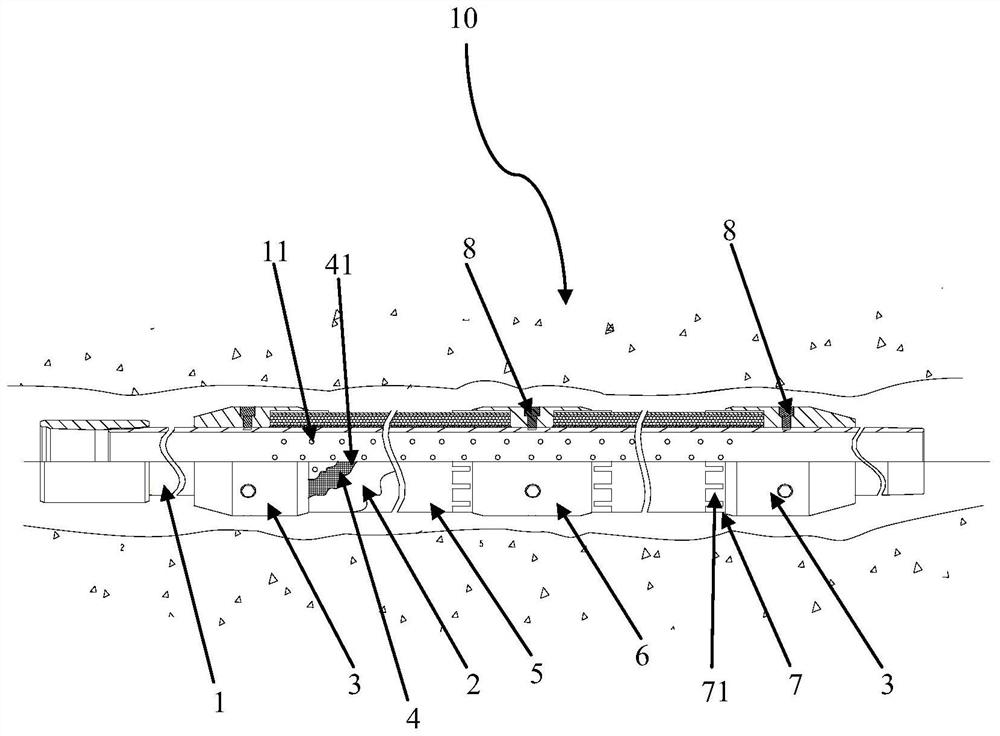

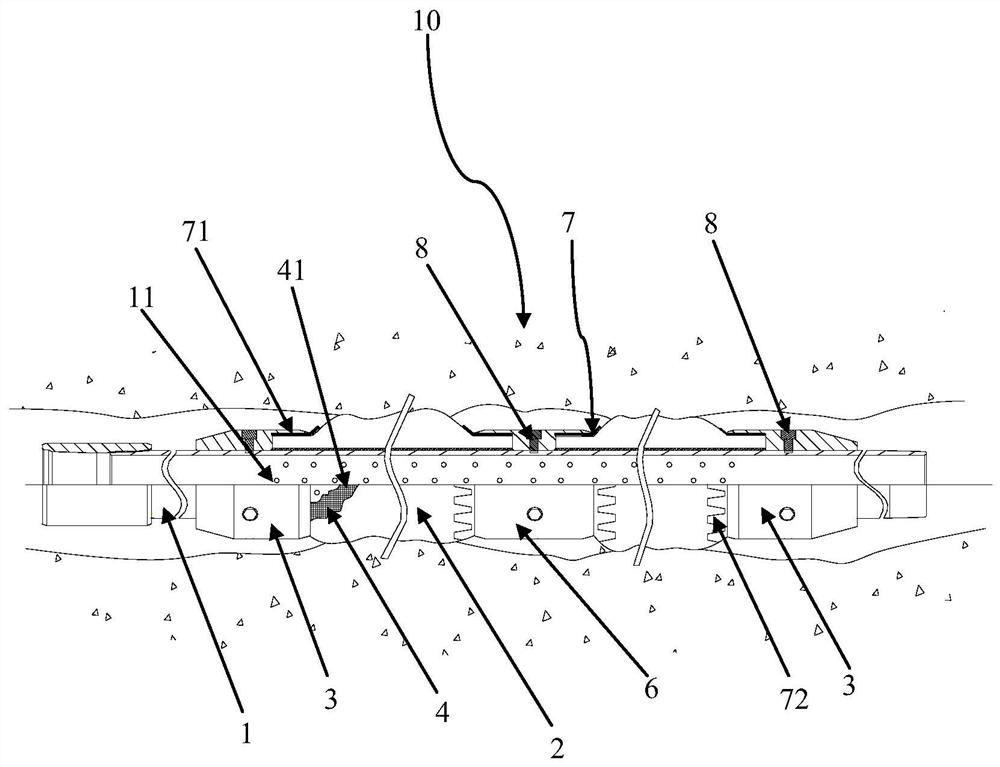

[0035] figure 1 The overall structure of the annulus self-filling sand control screen 10 before expansion is schematically shown in the embodiment of the present invention. figure 2 It schematically shows the overall structure of the annular self-filling sand control screen 10 in the embodiment of the present invention after expansion.

[0036] like figure 1 and figure 2 As shown, the annular self-filling sand control screen 10 according to the embodiment of the present invention includes a base pipe 1, a sand retaining layer 2 and a snap ring 3. Wherein, the sand retaining layer 2 is sheathed on the base pipe 1 , and the sand retaining layer 2 is fixed at both ends of the base pipe 1 through snap rings 3 . The base pipe 1 is provided with uniformly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com