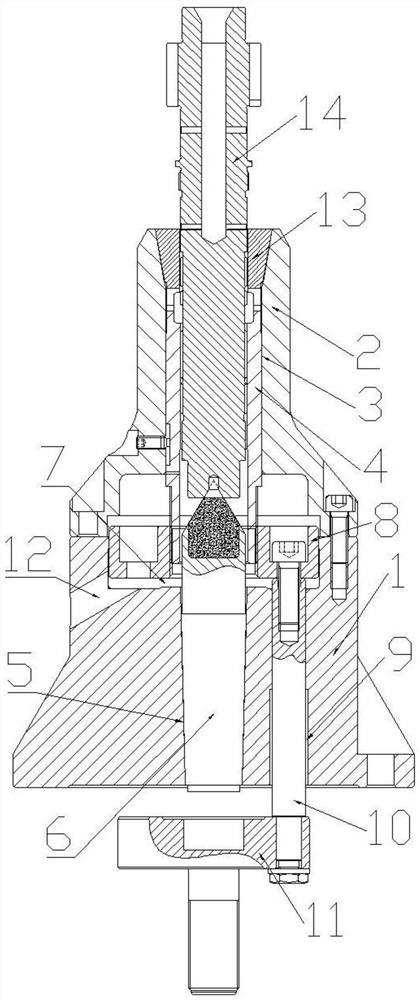

Hobbing clamp for intermediate shaft

A hobbing fixture and intermediate shaft technology, which is applied in the field of lathe clamping devices, can solve the problems of reducing the processing efficiency of intermediate shaft gears, and long time for top inspection and replacement, so as to improve processing efficiency and improve the efficiency of inspection and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

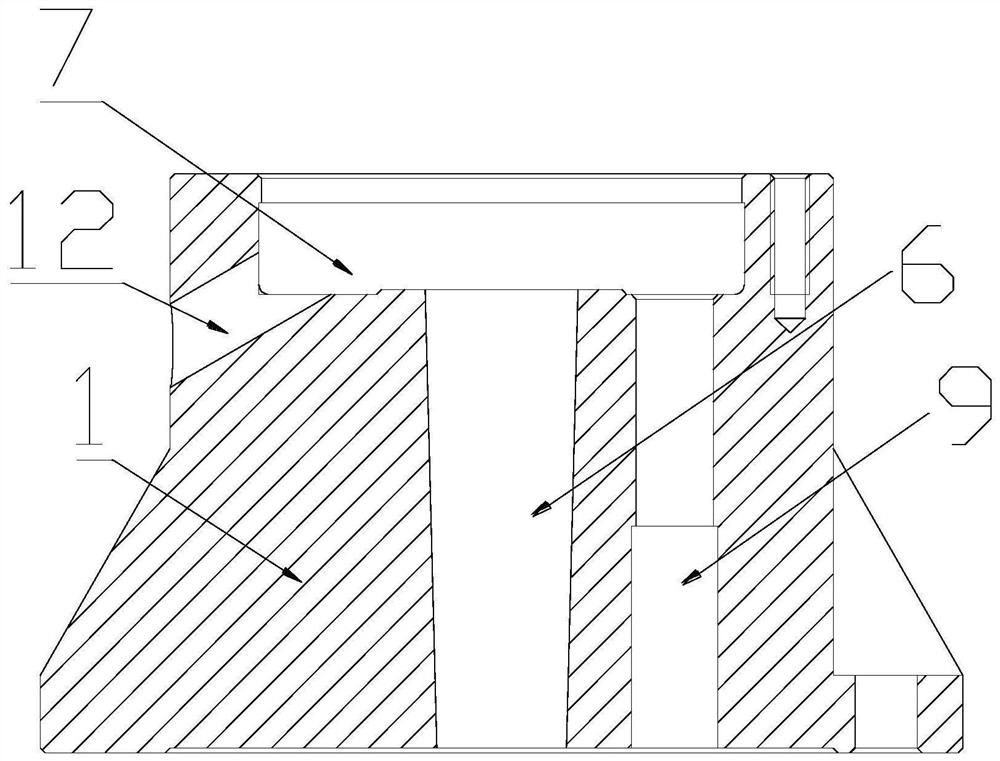

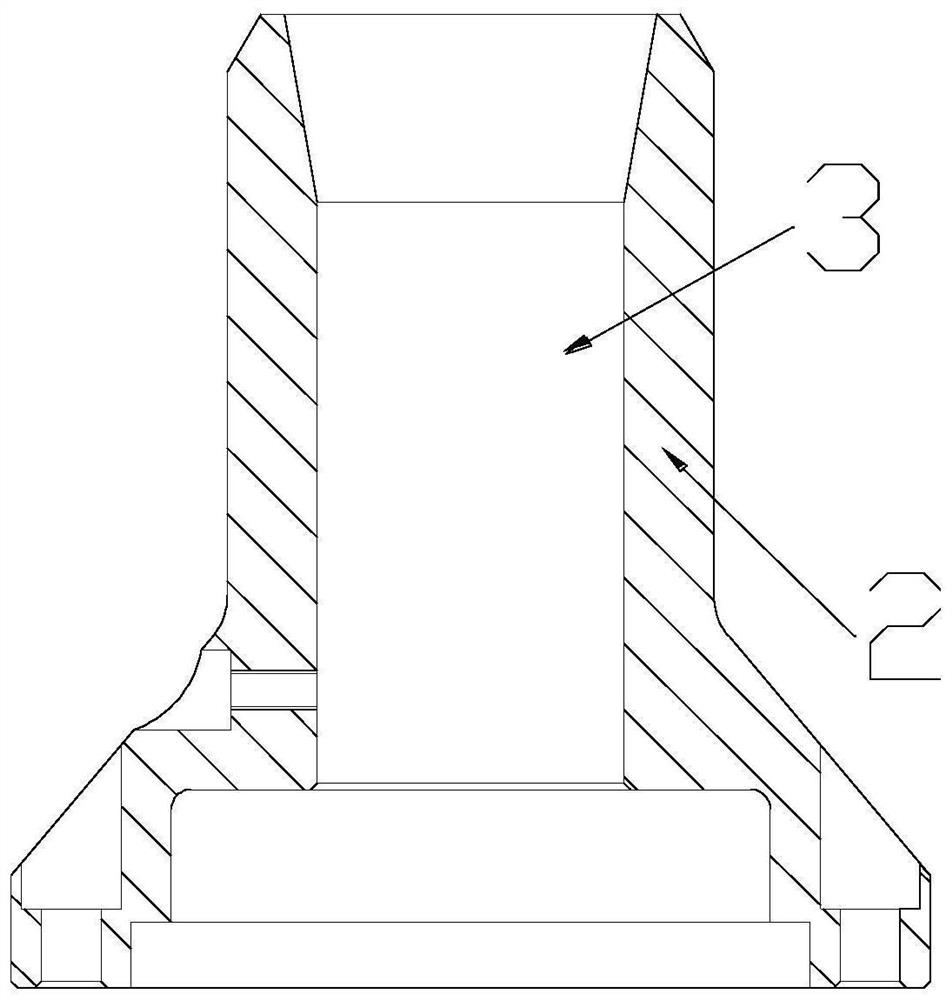

[0022] Such as Figure 1-Figure 5 As shown, a hobbing fixture for an intermediate shaft includes a base 1 and a chuck seat 2, the base 1 and the chuck seat 2 are detachably connected, and the chuck seat 2 is provided with a through hole 3, An installation sleeve 4 is slidably arranged in the through hole 3, and an elastic sleeve 13 is fixed on the end of the installation sleeve 4 away from the base 1. There is a mounting hole 5, the mounting hole 5 is in the shape of an inverted "eight", and a top 6 is arranged in the mounting hole 5, and the top 6 is provided with a mounting hole 5 adapted to the inverted "eight" shape. Slope, the top 6 is fixed to the mounting hole 5 by expansion, the base 1 is provided with a groove 7 on the side connected to the chuck seat 2, and a connecting seat 8 is arranged in the groove 7, so The connection seat 8 is fixedly connected with the installation sleeve 4, and the base 1 is also provided with a pull rod hole 9, and a pull rod 10 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com