Permanent magnet auxiliary synchronous reluctance motor for electric automobile

An auxiliary synchronous and electric vehicle technology, applied in electric vehicles, synchronous machines, synchronous machine parts, etc., can solve the problems of narrow high-speed field-weakening constant power range, low motor efficiency and power density, and large torque ripple. Improve the anti-demagnetization ability at low temperature, increase the volume of the accommodating groove, and reduce the effect of torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

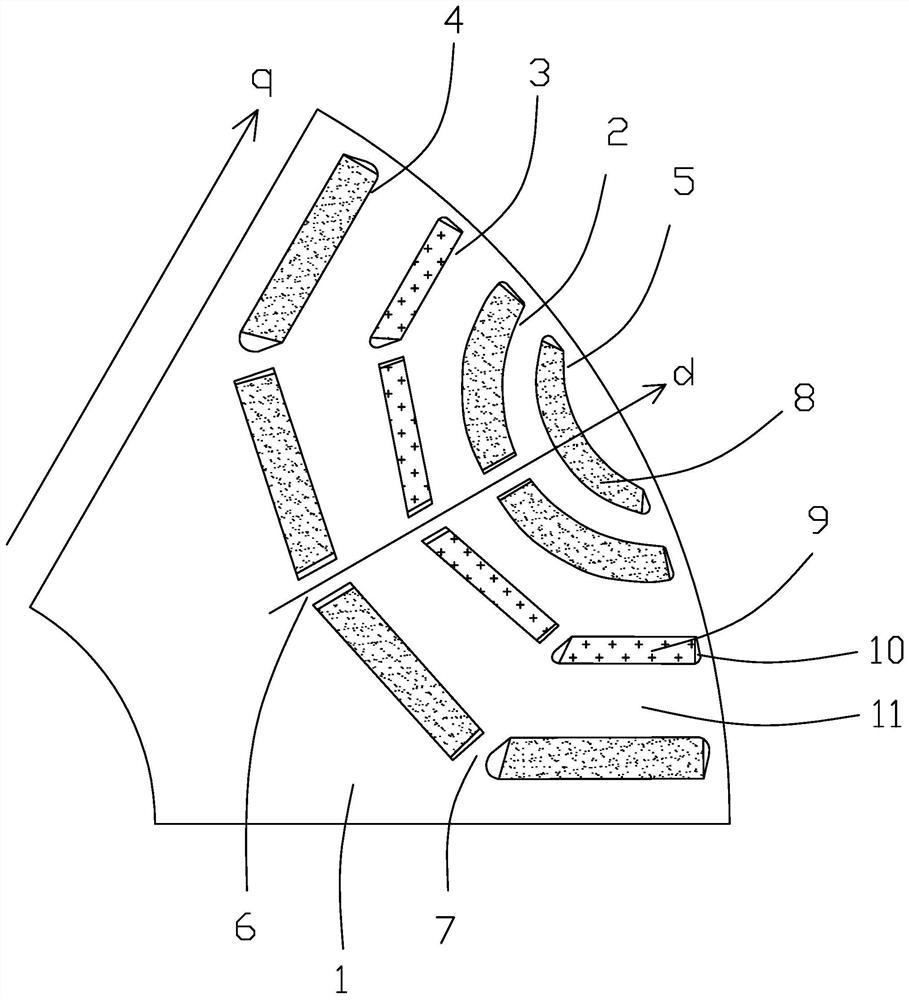

[0024] In this embodiment, a permanent magnet assisted synchronous reluctance motor for an electric vehicle, such as figure 1 As shown, the rotor core 1 is included, and a plurality of magnetic barrier groups are arranged axially on the rotor core, and the magnetic barrier groups include outer magnetic barriers 5, first magnetic barriers 2, The second magnetic barrier 3 and the third magnetic barrier 4,

[0025] The outer magnetic barrier is not provided with a partition. The first magnetic barrier is provided with a middle partition 6 , which separates the first magnetic barrier to form two accommodating grooves 10 . The second magnetic barrier and the third magnetic barrier are respectively provided with a middle partition 6 and side partitions 7 on both sides, which divide the third magnetic barrier and the fourth magnetic barrier into four accommodating slots 10 . The middle partitions of the first magnetic barrier, the second magnetic barrier and the third magnetic barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com