Bundled wire and three-dimensional design model construction method thereof

A technology of 3D design and wire harness, applied in design optimization/simulation, CAD based on constraints, special data processing applications, etc., can solve problems such as poor design quality, low authenticity of the 3D design model of wire harnesses, and failure to consider wire harnesses, etc., to achieve The effect of accurate spatial form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

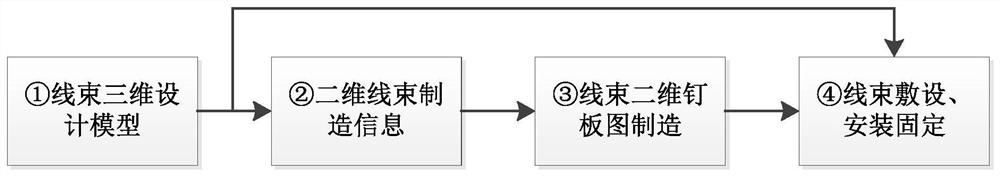

Method used

Image

Examples

specific Embodiment approach

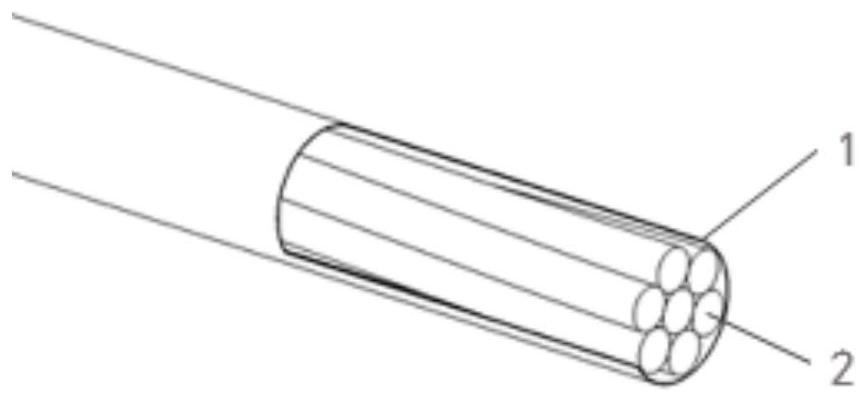

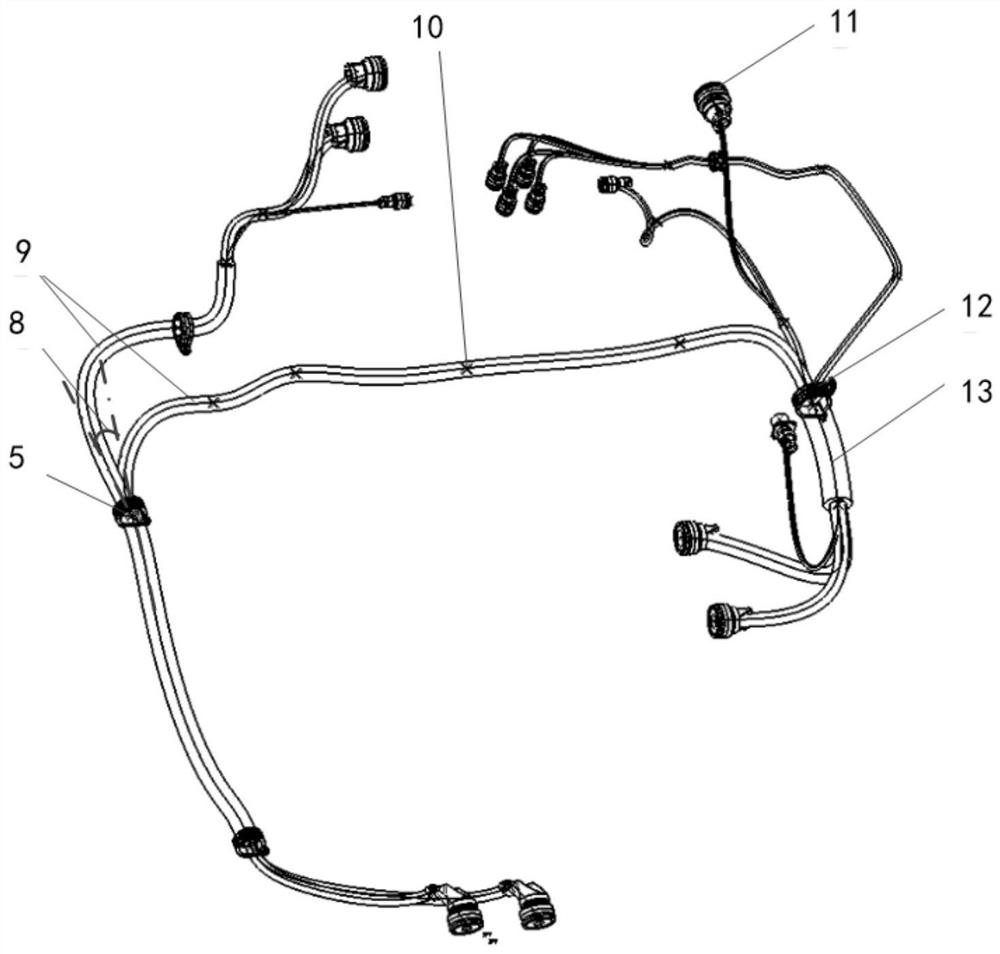

[0055] The specific embodiment of the present invention is as follows: as Figure 2-5 As shown, a bundled wire includes a plurality of bundled wire cores 2, the bundled wire has a coating 1 outside, the bundled wire has multi-level wire harness branches 9, and the upper-level branch 3 and the lower-level branch 6 are on the central axis of the branch The bifurcation point 5 is separated, and there is a branch bifurcation angle 8 between the upper-level branch 3 and the lower-level branch 6, specifically the angle between the upper-level branch central axis 4 and the lower-level branch central axis 7, A fixing clip 12 is provided at the bifurcation point 5 of the branch central axis, an electrical plug 11 is provided at the end of each wire harness branch 9, and a turn-back portion 16 is also provided at the bifurcation point 5 of the branch central axis;

[0056] Further, each next-level branch 6 includes at least two branches, and the turning portion 16 is set so that one of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com