Vacuum-assisted post-grouting device and method for cast-in-situ bored pile

A bored pile, vacuum-assisted technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of disturbed gravel layer, difficult grouting, long single pile grouting period, etc., to improve the pile body Effects of bearing capacity, reduction of post-grouting time, and improvement of post-grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] A vacuum-assisted post-grouting method for bored piles, such as figure 1 shown, including steps:

[0030] S1. Hole forming of bored piles—the hole depth, hole diameter and verticality are controlled during the construction process. Since a sand cushion layer 13 needs to be set at the bottom of the pile, it can be completed under the premise that the soil properties of the bearing layer are clear and the bearing capacity of the pile is not affected. The hole depth is one thicker than the designed drilling depth by the thickness of the sand cushion layer 13, and the thickness of the sand cushion layer 13 in this embodiment is 20-30 cm.

[0031] S2. Cleaning the hole for the first time - cleaning the pile hole and cleaning the residue in the drilling hole.

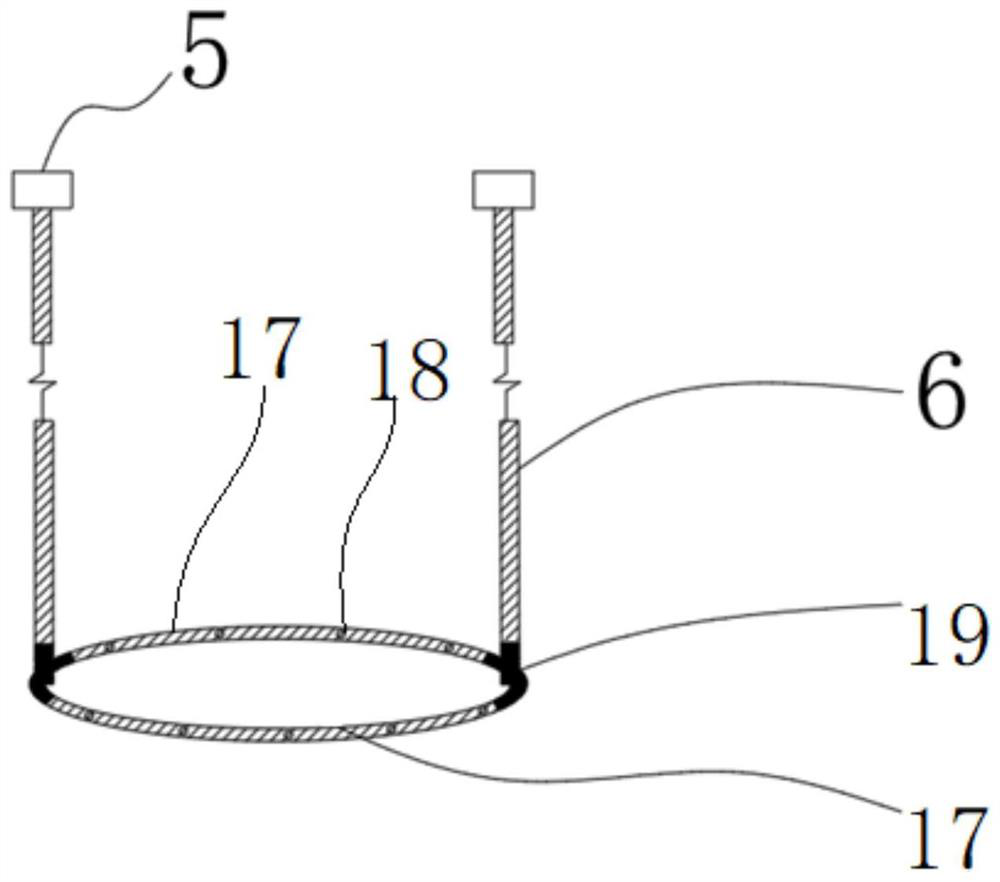

[0032] S3. Bind and fix the inner grouting pipe 6, the grouting device 8 and the inner vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com