Auxiliary jig for PCB thin plate production

A production aid and fixture technology, used in electronic circuit testing, measuring devices, instruments, etc., can solve the problems of slow fixing, time-consuming, skewed, etc., to save clamping time, avoid detection on both sides, and improve detection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

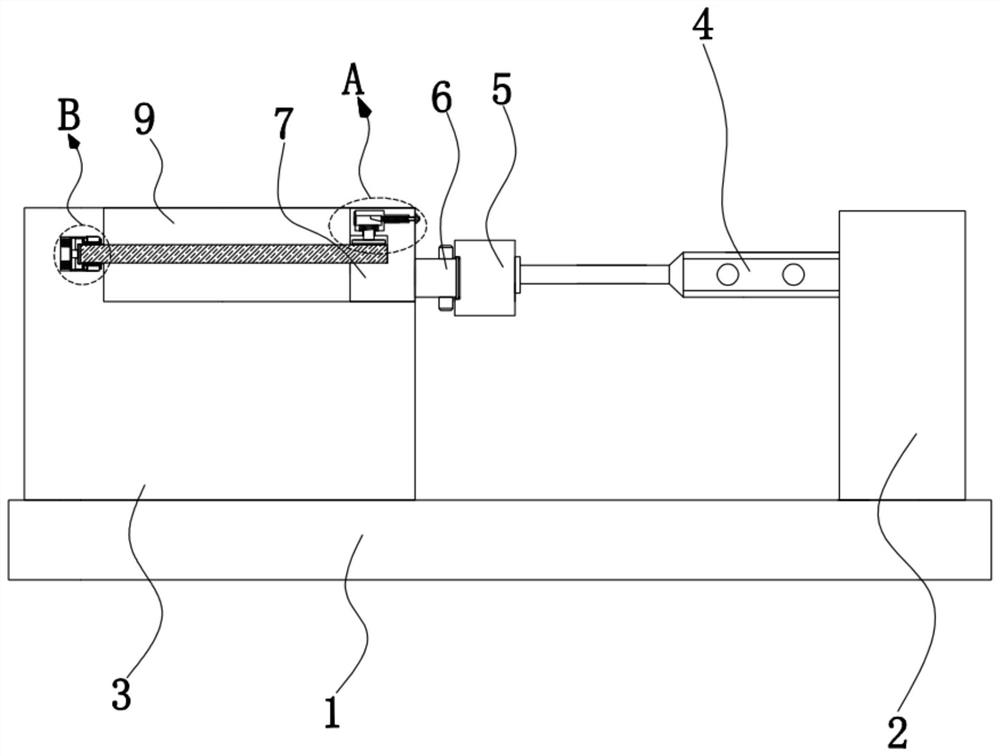

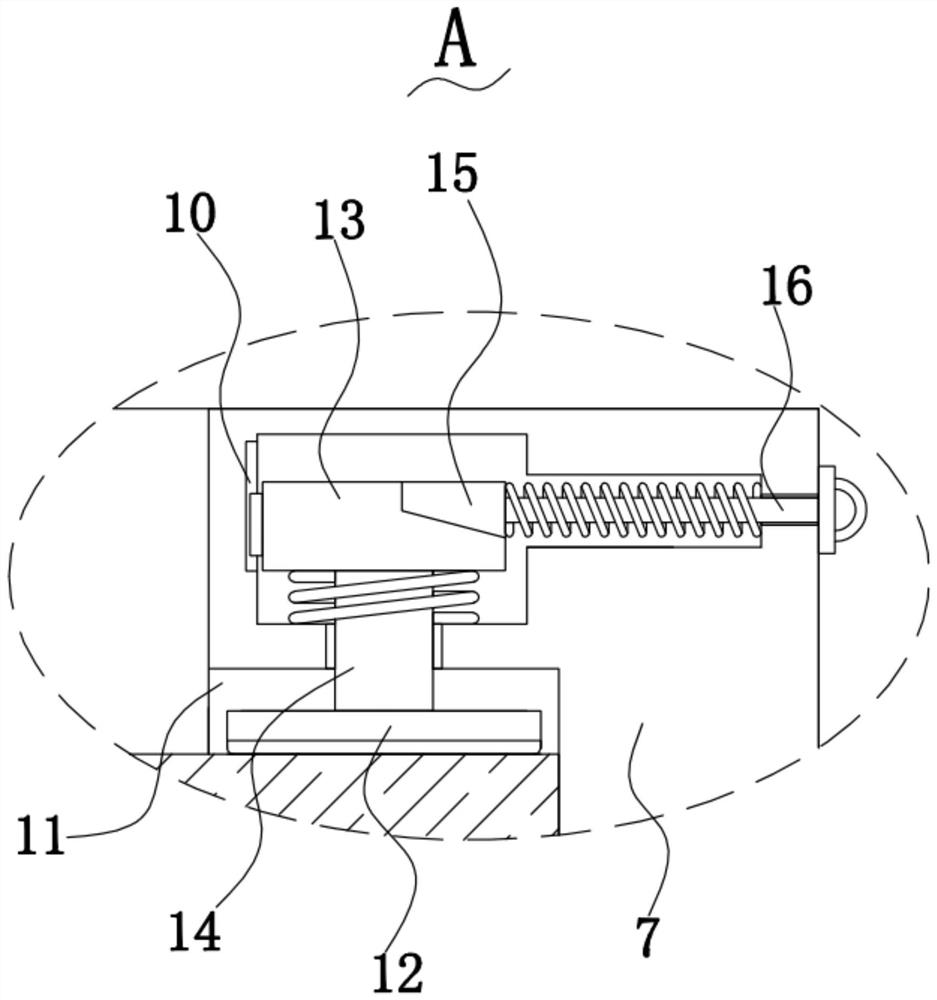

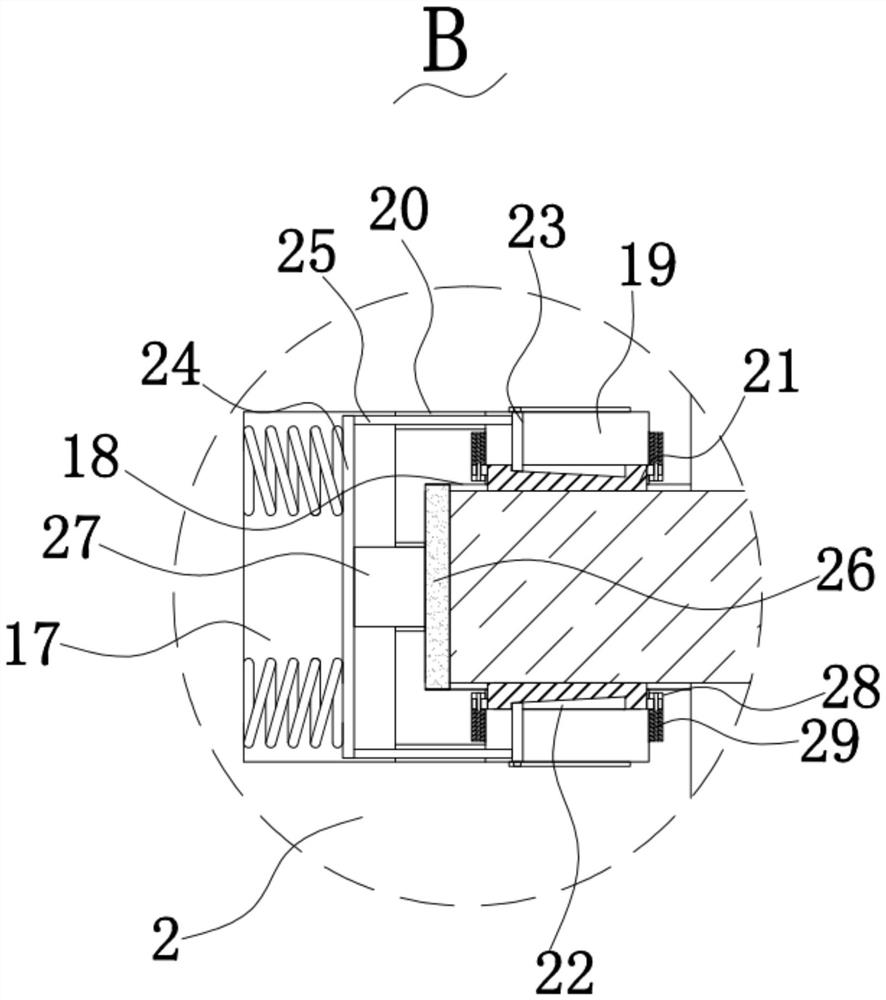

[0026] Please refer to Figure 1-Figure 4 , in the first embodiment of the present invention, the auxiliary jig for PCB sheet production includes: a base 1; a first fixed seat 2, the first fixed seat 2 is fixedly installed on the top of the base 1; a second fixed seat 3 , the second fixed base 3 is fixedly installed on the top of the base 1; hydraulic cylinder 4, the hydraulic cylinder 4 is fixedly installed on one side of the outer wall of the first fixed base 2; connecting block 5, the connecting block 5 The block 5 is fixedly mounted on the telescopic shaft of the hydraulic cylinder 4; the rotating rod 6 is mounted on the outer wall of one side of the connecting block 5; the clamping block 7 is fixed Installed on the end of the rotating rod 6 away from the connecting block 5; the motor 8, the motor 8 is fixedly installed on one side of the outer wall of the connecting block 5; the placing groove 9, the placing groove 9 is opened in the The top of the second fixed seat 3; t...

no. 2 example

[0038] Based on the auxiliary fixture for PCB sheet production provided in the first embodiment of the present application, the second embodiment of the present application proposes another auxiliary fixture for PCB sheet production. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0039] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0040] Please refer to Figure 5 , PCB sheet production auxiliary jig also includes a fifth groove 30, the fifth groove 30 is opened on one side of the outer wall of the second fixing seat 3, fixed on one side of the outer wall of the second fixing seat 3 A connection frame 31 is installed, a cleaning fan 32 is fixedly installed on one side inner wall of the connection frame 31, a sixth groove 33 is provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com