A kind of composite modified biochar stabilizer and its preparation method and application

A biomass charcoal and composite modification technology, applied in the environmental field, can solve the problems of high preparation cost, complicated construction process, long repair period, etc., and achieve simple and easy modification operation, low construction cost, and short stabilization period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

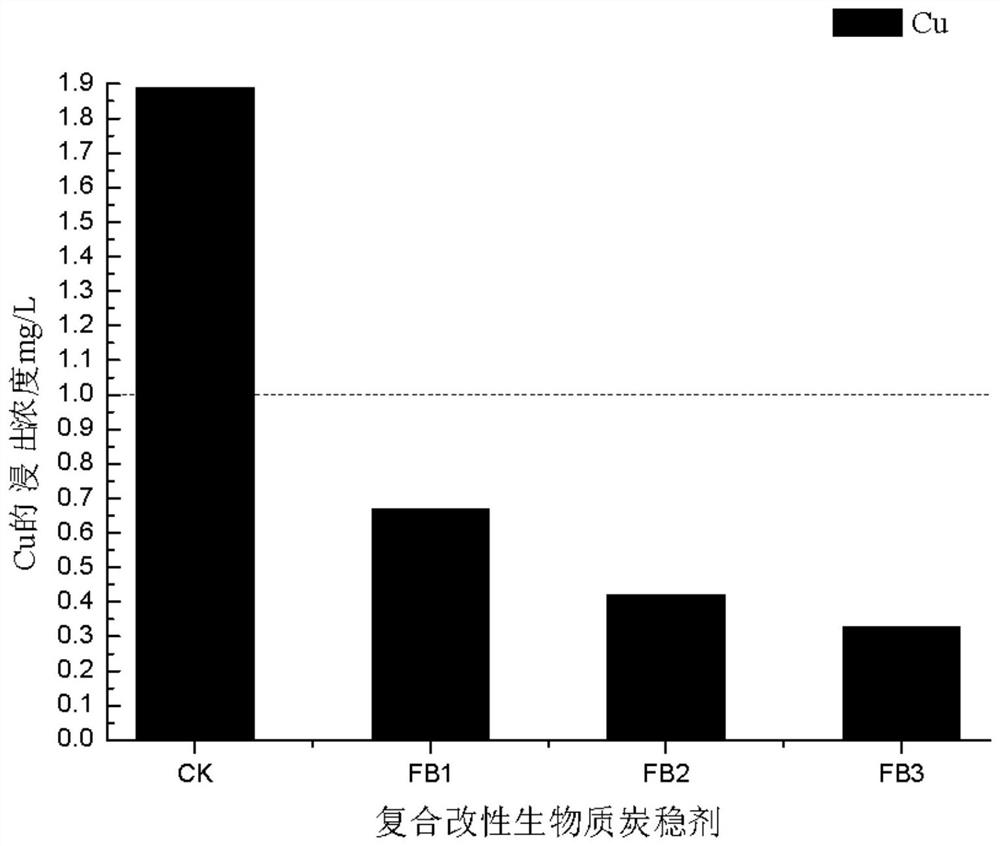

Embodiment 1

[0041] In parts by weight: 2 parts of modified biochar; 1 part of lime; 0.5 part of potassium dihydrogen phosphate. Stir the modified biochar, lime and potassium dihydrogen phosphate in a mixing equipment for 2 hours and mix evenly to obtain the composite modified biochar stabilizer FB1. The prepared stabilizer is stored indoors under sealed and dry conditions.

[0042] The preparation method of described modified biochar comprises steps:

[0043](1) Pass the biochar derived from agricultural waste corncobs through a 100-mesh sieve, and put the undersieve into FeSO with a concentration of 0.4mol / L according to the solid-to-liquid ratio of 1g:8mL 4 In the solution, add NaOH solution after mixing to adjust the pH of the mixture to 6, continue to stir for 15 minutes and then soak for 24 hours;

[0044] (2) Solid-liquid separation is carried out after soaking, and the resulting solid product is dried at 100°C to constant weight;

[0045] (3) The obtained dried product was crushe...

Embodiment 2

[0048] In parts by weight: 2 parts of modified biochar; 1.5 parts of lime; 1 part of potassium dihydrogen phosphate. Stir the modified biochar, lime and potassium dihydrogen phosphate in the mixing equipment for 1.5 hours and mix evenly to obtain the composite modified biochar stabilizer FB2. The prepared stabilizer is stored in a sealed and dry room .

[0049] The preparation method of described modified biochar comprises steps:

[0050] (1) The biochar sourced from agricultural waste corncobs is passed through a 100-mesh sieve, and the under-sieve is put into FeSO with a concentration of 0.5mol / L at a solid-to-liquid ratio of 1g:10mL 4 In the solution, add NaOH solution after mixing to adjust the pH of the mixture to 7, continue to stir for 30 minutes and then soak for 24 hours;

[0051] (2) Solid-liquid separation is carried out after soaking, and the obtained solid product is dried to constant weight at 105°C;

[0052] (3) The obtained dried product was crushed and pass...

Embodiment 3

[0055] In parts by weight: 4 parts of modified biochar; 1 part of lime; 0.5 part of potassium dihydrogen phosphate. Stir the modified biochar, lime and potassium dihydrogen phosphate in the mixing equipment for 1.5 hours and mix evenly to obtain the composite modified biochar stabilizer FB3. The prepared stabilizer is stored in a sealed and dry room .

[0056] The preparation method of described modified biochar comprises steps:

[0057] (1) Pass the biochar derived from agricultural waste corncobs through a 100-mesh sieve, and put the undersieve into FeSO with a concentration of 0.9mol / L according to the solid-to-liquid ratio of 1g:15mL 4 In the solution, add NaOH solution after mixing to adjust the pH of the mixture to 7, continue to stir for 30 minutes and then soak for 36 hours;

[0058] (2) Solid-liquid separation is carried out after soaking, and the obtained solid product is dried to constant weight at 105°C;

[0059] (3) The obtained dried product was crushed and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com