Intelligent deviation rectifying structure for wide abrasive belt

A kind of abrasive belt and intelligent technology, applied in the field of intelligent deviation correction structure of wide abrasive belt, can solve the problems of belt deviation, narrow belt circumference error range, low degree of automation, etc., achieve fine wire drawing pattern, save machine adjustment time , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

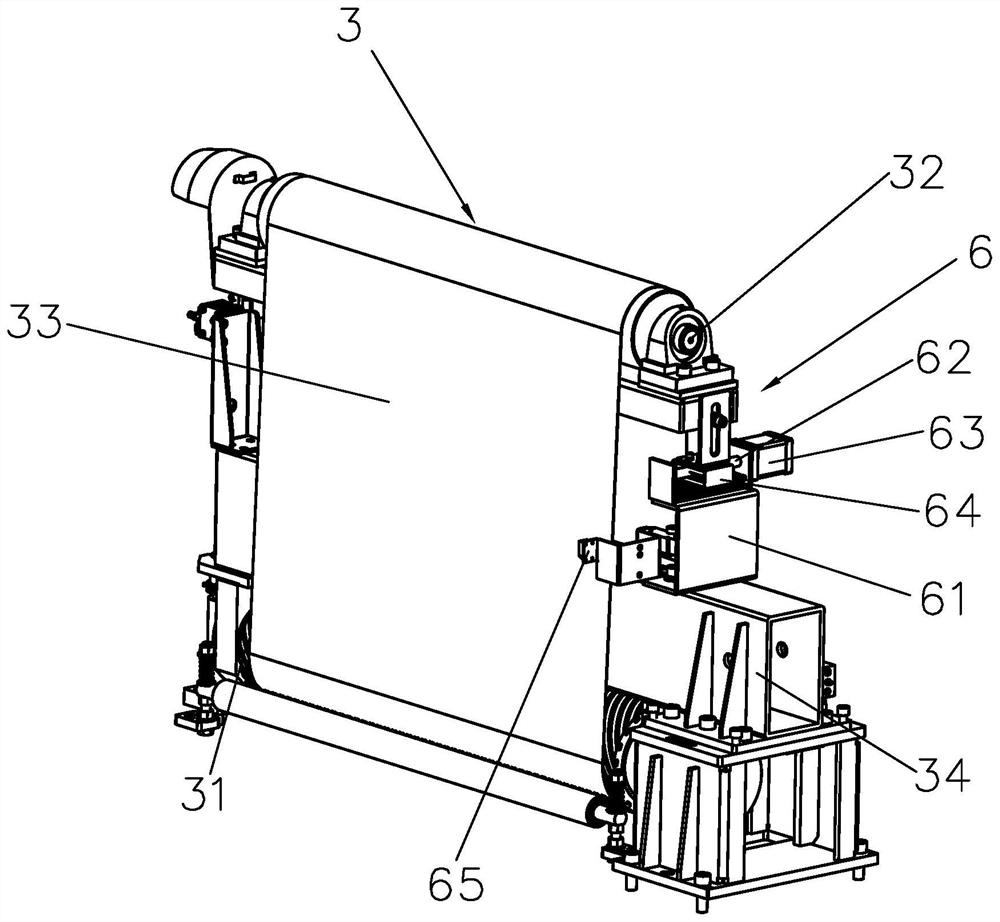

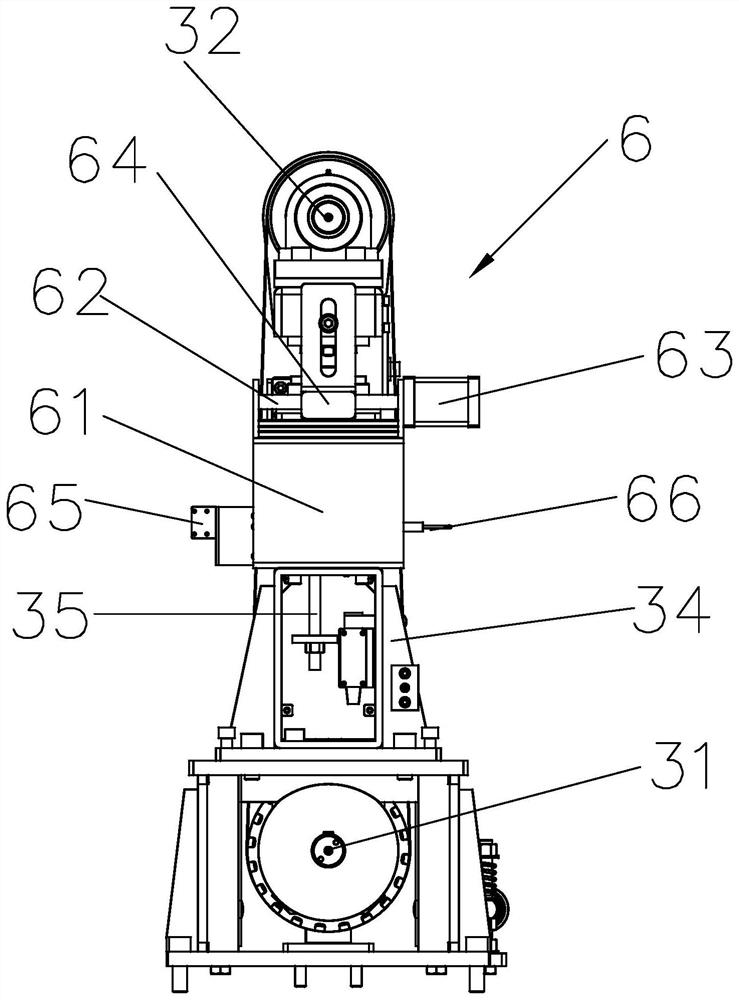

[0016] Such as figure 1 As shown, the wide-width abrasive belt intelligent deviation correction structure provided in this embodiment includes a frame 1, a controller, a wire drawing touch roller 2 arranged on the frame 1, a wire drawing tension roller 3, and a wire drawing touch roller wound around the wire drawing touch roller. 2 and the drawing belt 4 between the drawing tension roller 3, the frame 1 is fixed with a fixed beam 5, the fixed beam 5 is located between the drawing contact roller 2 and the drawing tension roller 3, and the drawing tension roller 3 passes through the axis The adjustment shaft 7 extending in the vertical direction is rotatably arranged on the fixed beam 5 , and a deviation correction device 6 for adjusting the wire drawing tension roller 3 is arranged between the fixed beam 5 and the wire drawing tension roller 3 .

[0017] The automatic deviation correction device in the present invention reduces the actual operation procedures required by worker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com