Crane capable of adjusting counterweight position

A counterweight position and crane technology, which is applied to cranes and other directions, can solve the problems of easy wear and tear of the counterweight support slideway, and achieve the effects of smooth operation, reliable guidance, and operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

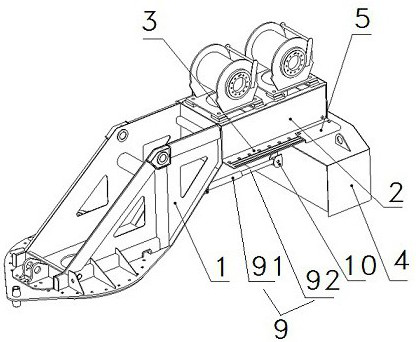

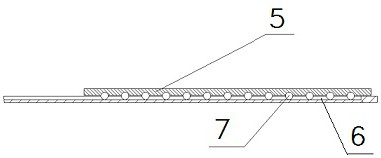

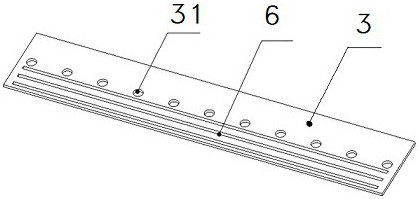

[0029] A specific embodiment of the crane with adjustable counterweight position of the present invention, such as figure 1 As shown, the crane with adjustable counterweight position (hereinafter referred to as the crane) includes the main body of the crane and the counterweight. The main body of the crane includes the bracket 1 and the hoisting box 2. The bottom of the hoisting box 2 is provided with a support plate 3, and the counterweight 4 passes through The hanging lugs 5 are guided and supported on the support plate 3 . Specifically, such as figure 2 As shown, the support plate 3 is provided with three rolling grooves 6 extending along the guiding movement direction of the counterweight 4, and the two ends of the rolling groove 6 in the length direction are blind ends provided with a blocking structure. The side wall of the groove is formed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com