Highland barley and triticale bread and making method thereof

A production method and wheat technology, which are applied in the processing of dough, baking, and baked goods with modified ingredients, etc., can solve the problems of poor quality and taste of highland barley bread, flat bread shape, and poor quality of highland barley bread, etc. Excellent, improve quality, excellent appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

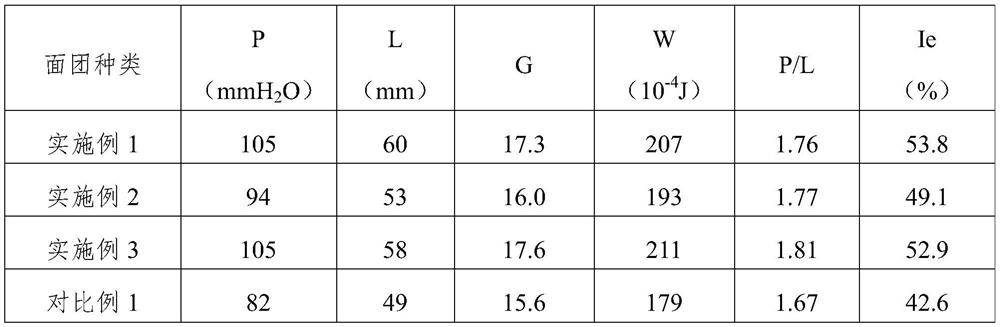

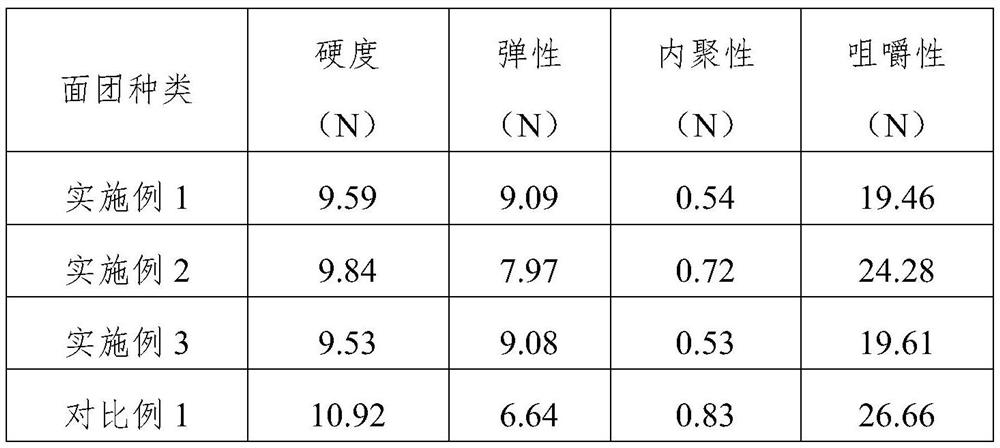

Embodiment 1

[0046] The present embodiment provides a kind of highland barley triticale bread, is made up of the component of following raw material:

[0047] 1000 parts of compound flour (200 parts of highland barley, 200 parts of black wheat, 600 parts of high-gluten flour), 8 parts of gluten powder, 10 parts of yeast, 5 parts of improver, 500 parts of water, 100 parts of eggs, 10 parts of salt, white 100 parts sugar, 100 parts butter, 200 parts milk powder.

[0048] The highland barley and triticale bread is prepared by the following production method:

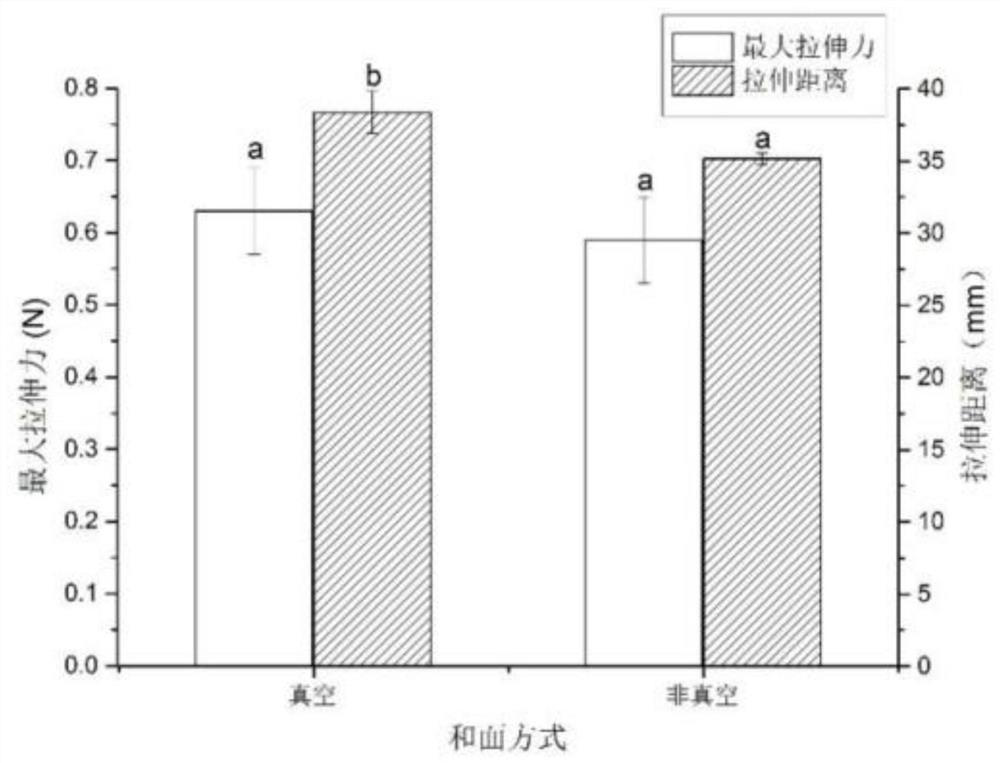

[0049]1. After mixing the raw materials evenly, under the conditions of a vacuum of 0.06Mpa and a temperature of 4°C (the temperature of the noodle bowl), knead the dough in the order of 60rpm for 2min, 80rpm for 8min, and 120rpm for 12min to obtain a shaped dough;

[0050] 2. Divide the shaped flour into groups and round to obtain a dough of about 300g;

[0051] 3. Then place the dough at a temperature of 27°C and a humidity of 85%, ...

Embodiment 2

[0054] This embodiment provides a kind of highland barley triticale bread, and the only difference from Embodiment 1 is that in the production method, the degree of vacuum in step 1) is different; the degree of vacuum is replaced by "0.04Mpa".

Embodiment 3

[0056] This embodiment provides a kind of highland barley triticale bread, and the only difference from Embodiment 1 is that in the manufacturing method, the degree of vacuum in step 1) is different; the degree of vacuum is replaced by "0.08Mpa".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com