An energy-saving busway

A technology of busway and annular groove, applied in the field of busway, can solve the problems of the influence of the use and installation of the busway, the deformation of the connection, and the protection of the connection that cannot be connected, so as to improve the load-bearing effect, the installation method is simple and flexible, and the maintenance is convenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

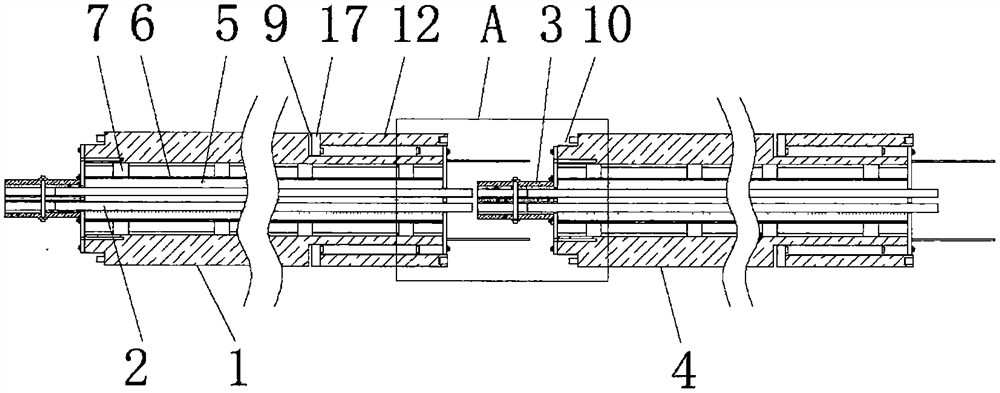

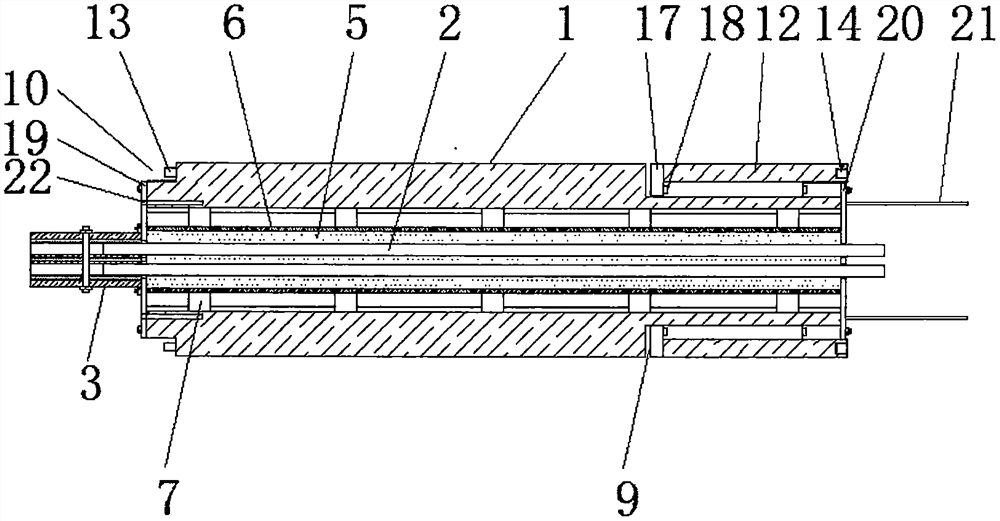

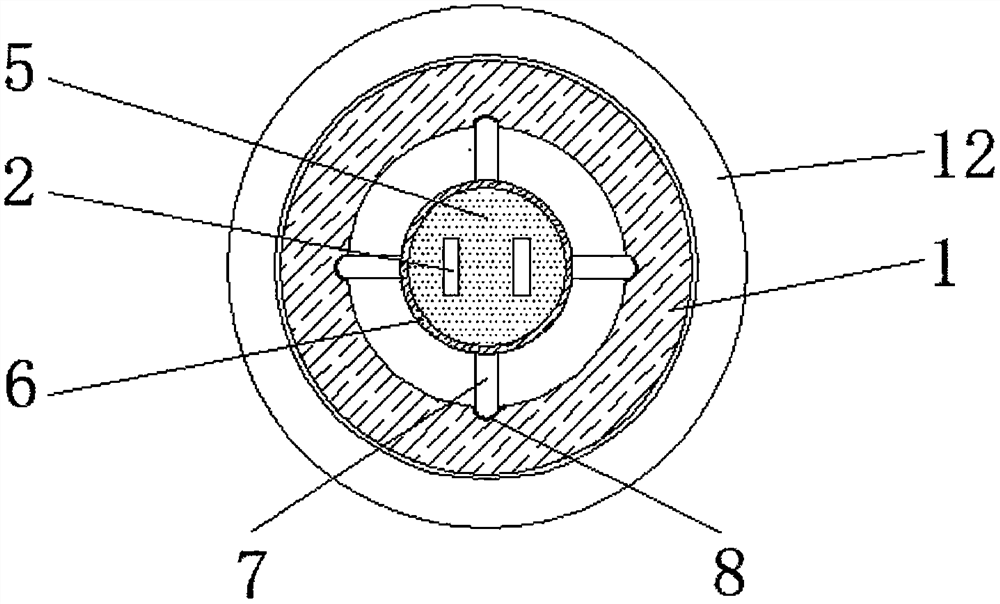

[0027] Such as Figure 1-4 Shown is an energy-saving busway. The tubular busway has a tubular shell made of metal, including a tubular shell 1 and a tubular shell 2 4. The interior of the tubular shell 1 and the tubular shell 2 are respectively passed through an insulator The conductive copper bar 2 is connected, and the conductive copper bar 2 on the tubular shell one 1 is connected with the conductive copper bar 2 on the tubular shell two 4 through the connector 3, the connector 3 includes the shell, is set on the shell and The jack for the insertion of the conductive copper bar 2, the conductor provided inside the housing and used for the electrical connection of the conductive copper bar 2 on the two bus ducts, and the insulating layer provided on the conductor, the housing is connected to the conductive conductor through the insulating layer. Body connection, one end of the housing is connected with the baffle plate one 19 through the connection block 23;

[0028] The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com