Deep hole uncoupled charge aqueous medium extruding and loosening blasting assembly and blasting method

A technology of loose blasting and liquid medicine, applied in blasting and other directions, can solve the problems of unacceptable, difficult charge, small hole diameter, etc., to achieve the effect of ensuring the speed and efficiency of propulsion, reducing equipment maintenance costs, and blasting with small rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

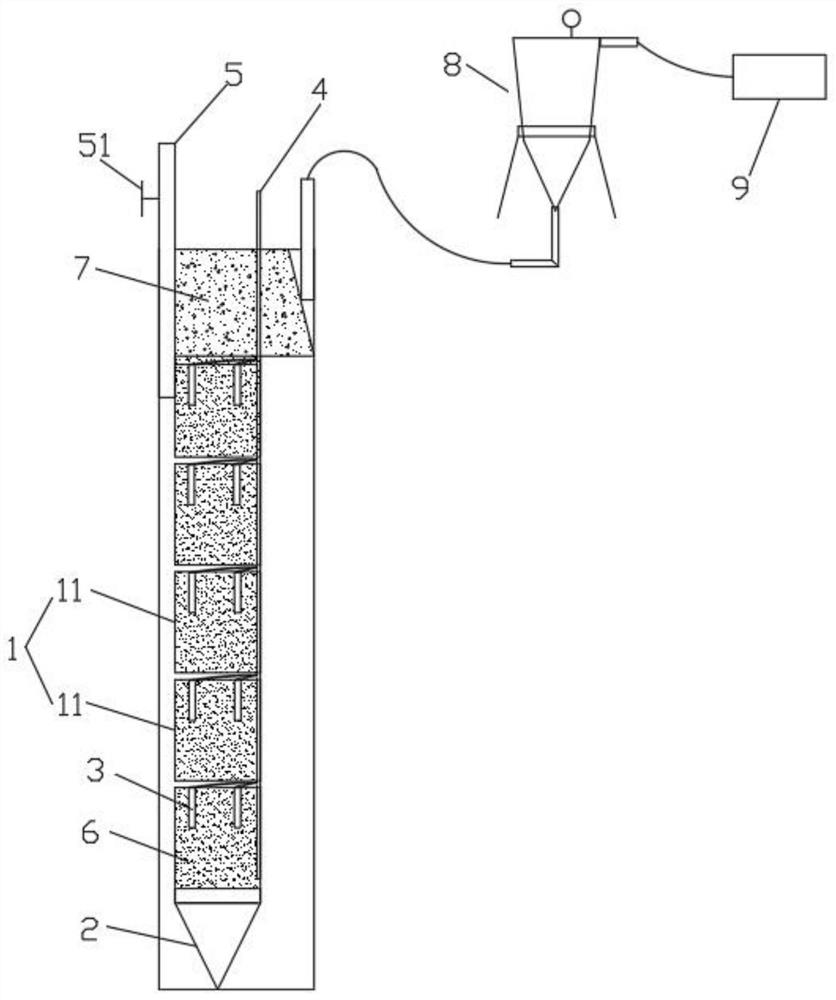

[0034] Example: such as figure 1 As shown, the deep hole uncoupled charging water medium extrusion loosening blasting assembly of this embodiment includes a drug tube 1, a charge guide 2, multiple sets of primers 3, a bus bar 4 and a water injection tube 5, and one end of the drug tube 1 extends At the bottom of the drilled hole, the other end is close to the hole of the drilled hole. A water injection cavity is formed between the drug tube 1 and the wall of the drilled hole. The drug charge guide 2 is installed on one end of the drug tube 1. The drug tube 1 is filled with explosives 6, multiple sets of primers 3 are installed in the explosives 6 at intervals along the long axis of the drug tube 1, one end of the busbar 4 extends into the drug tube 1, and connects with multiple sets of explosives 6 respectively. Wiring connection, the other end is placed outside the borehole, one end of the above-mentioned water injection pipe 5 extends into the water injection chamber, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com