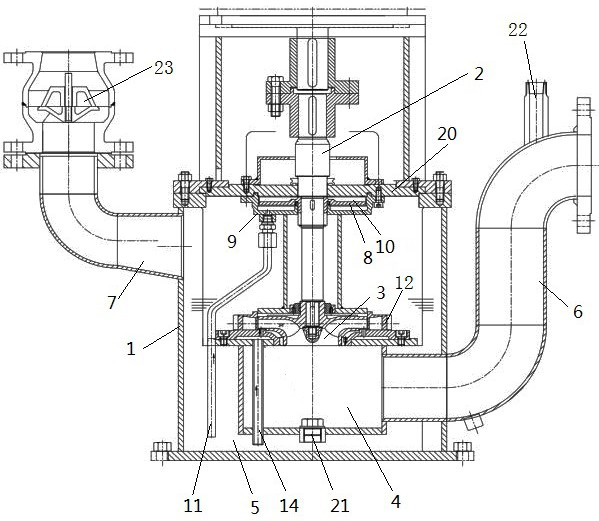

Vertical self-priming pump

A self-priming pump and vertical technology, applied in the field of vertical self-priming pumps, can solve the problems affecting the self-priming of the pump, the effect of gas-liquid mixing and separation, and reduce the working efficiency of the self-priming pump, and achieve the effect of rapid self-priming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

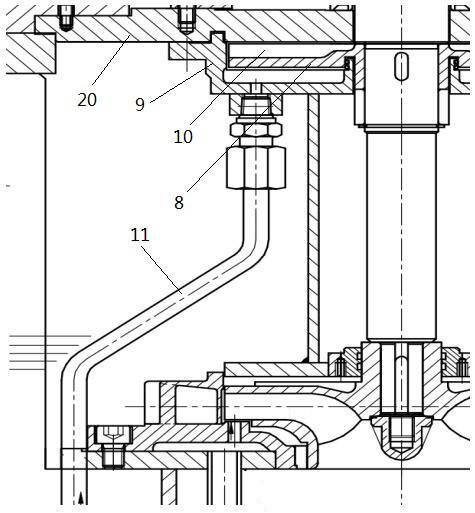

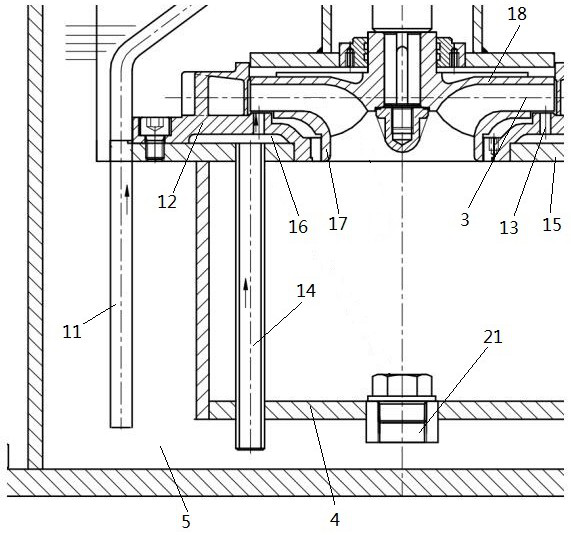

[0019] In order to make the structure and function of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0020] The vertical self-priming pump in the form of auxiliary impeller seal will install a set of auxiliary impellers on the shaft. The main function of the auxiliary impellers is to generate pressure opposite to the direction of the main impeller to achieve shaft sealing. The shaft seal does not require any pump during the entire service life of the pump. maintain. In the process of realizing self-priming, as the vacuum degree in the pump body increases, air intake will appear at the auxiliary impeller, which will affect the self-priming of the pump and reduce the working efficiency of the self-priming pump.

[0021] For the above problems, the present invention adopts the auxiliary impeller seal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com