Reverse circulation forward sand washing type horizontal well rotational flow sand washing tool

A horizontal well and reverse circulation technology, which is applied in the direction of flushing wellbore, wellbore/well components, earthwork drilling and production, etc., can solve the problem of insufficient ability of sand flushing and well flushing, shorten the time of sand flushing operation, and enhance sand flushing Well capacity, the effect of increasing the impact force of the liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention, but not to limit the scope of the present invention.

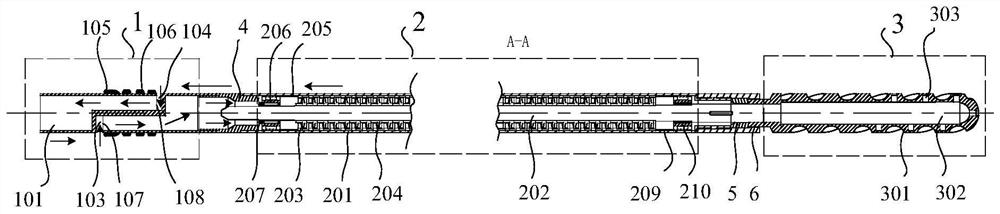

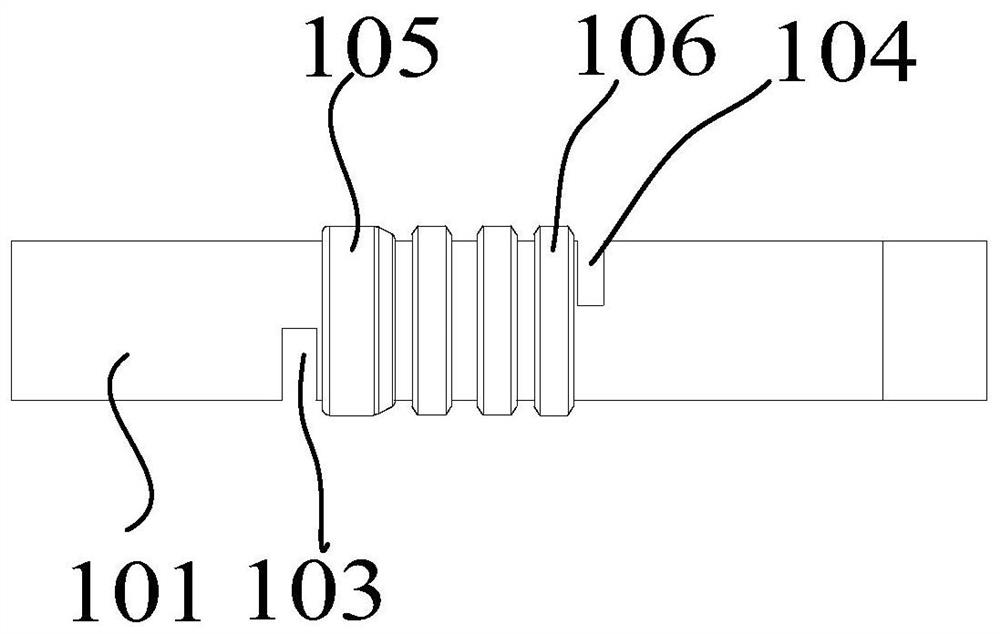

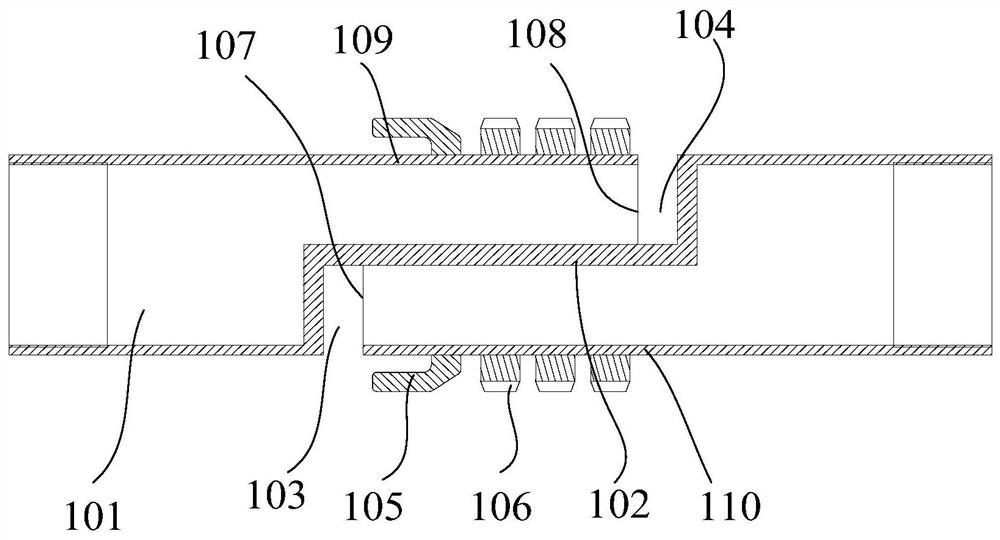

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a reverse circulation positive sand washing horizontal well swirl sand washing tool, the swirl sand washing tool is sleeved in a sleeve (not shown in the figure), and the swirl sand washing tool is The flow sand flushing tool includes a fluid reversing device 1 , a turbo swirling device 2 and a rotary flushing device 3 . The fluid reversing device 1 is mainly used for reversing and separating the flushing fluid and the sand-mixing fluid produced after flushing, and the turbo-increasing device 2 is mainly used for pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com