Crane translation device

A technology of translation device and crane, which is applied in the direction of load block, transportation and packaging, and load hanging components, etc., which can solve problems such as unfavorable hoisting use, inability to flexibly adjust the hoisting device, and inappropriate hoisting of items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

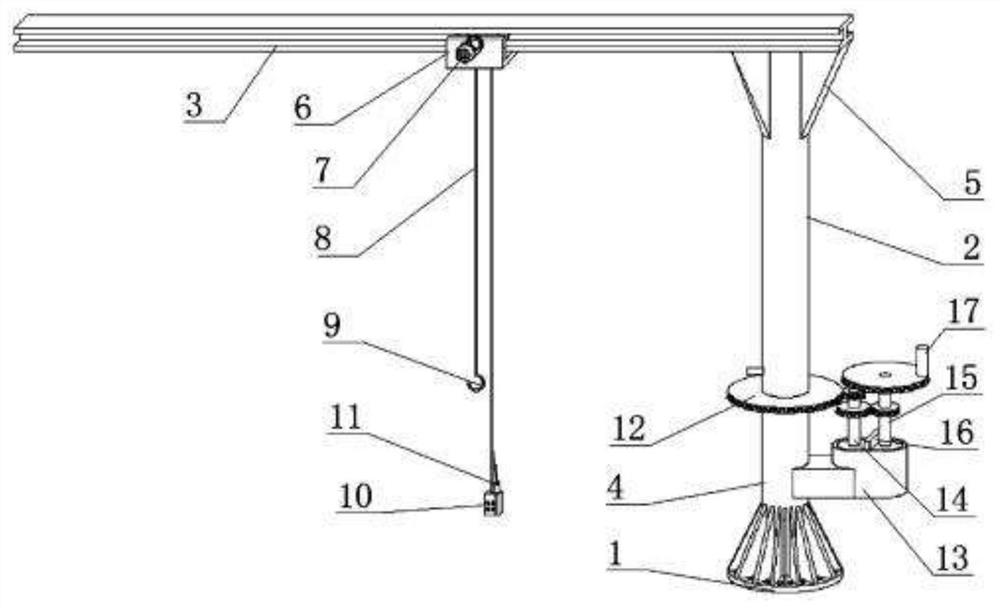

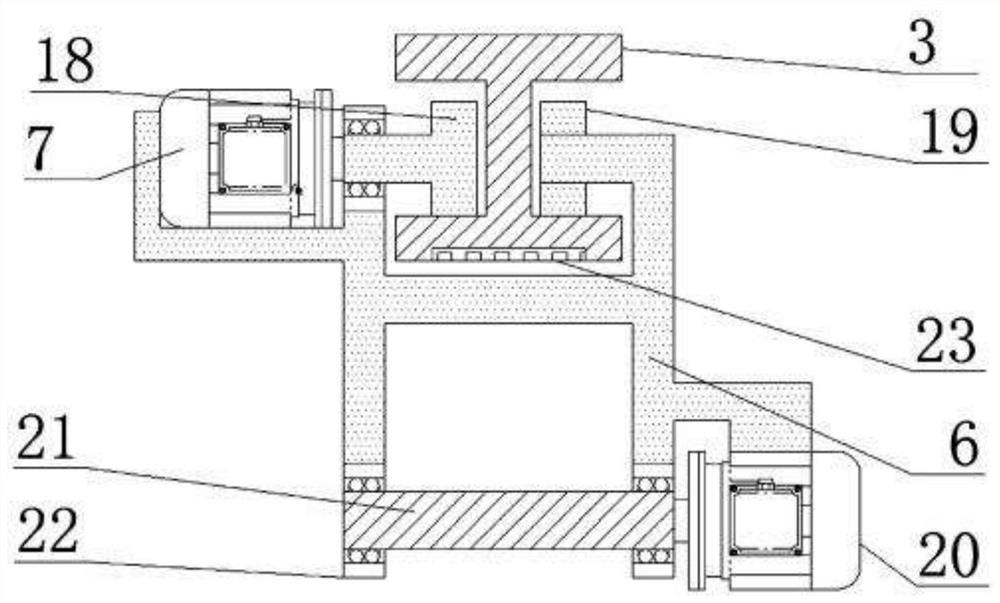

[0031]As a preferred embodiment of the present invention, the first gear set 14 is welded on the output shaft of the third motor 28, the driving wheel 18 is welded on the output shaft of the first motor 7, and the reel 21 is welded on the second motor 20. on the output shaft.

[0032] As a preferred embodiment of the present invention, the first gear set 14 is installed on the top of the clamping plate 27 through a rotating shaft, the first gear set 14 meshes with the second gear set 15 and the gear 12, and the second gear set 15 and The gears 12 mesh.

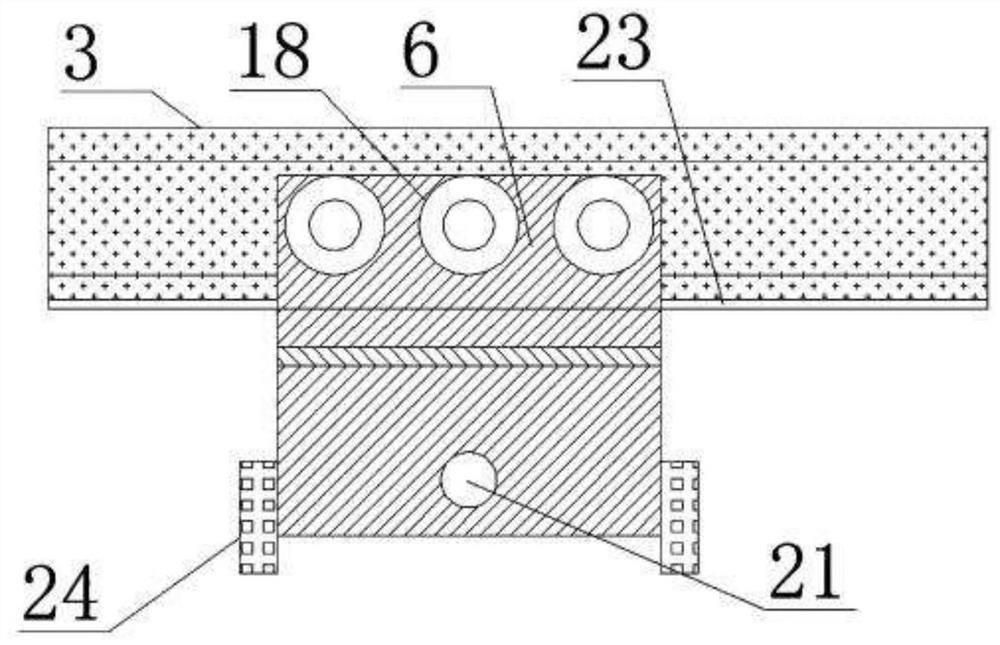

[0033] As a preferred embodiment of the present invention, both the driving wheel 18 and the roller 19 are stuck inside the I-beam 3 , and the driving wheel 18 is mounted on the movable frame 6 through a bearing 22 .

[0034] As a preferred embodiment of the present invention, a stopper 16 is welded on the top of the fixing sleeve 13 , and the stopper 16 is matched with the clamping plate 27 .

[0035] As a preferred embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com