Compact modular variable rigidity joint

A variable stiffness, modular technology, applied in manipulators, manufacturing tools, joints, etc., can solve the problems that rigid joints cannot well meet the operational requirements of collaborative robots, cannot achieve joint load decoupling, and joint stiffness linearity is poor. , to achieve the effect of compact design, good linearity, and elimination of additional bending moments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

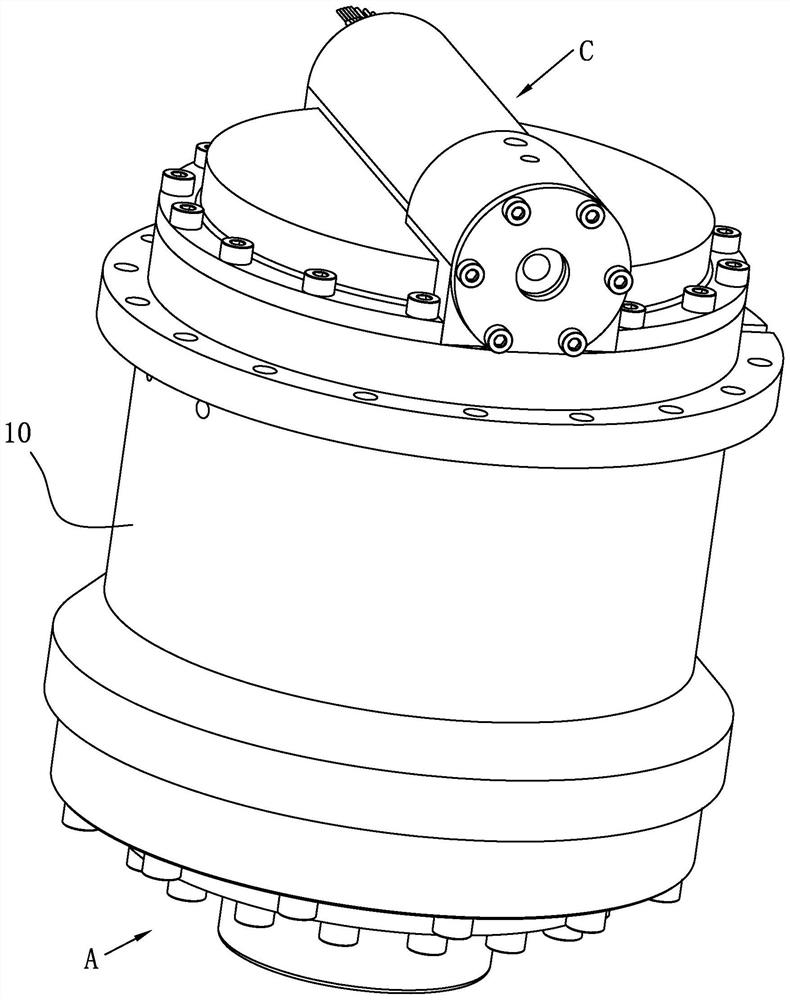

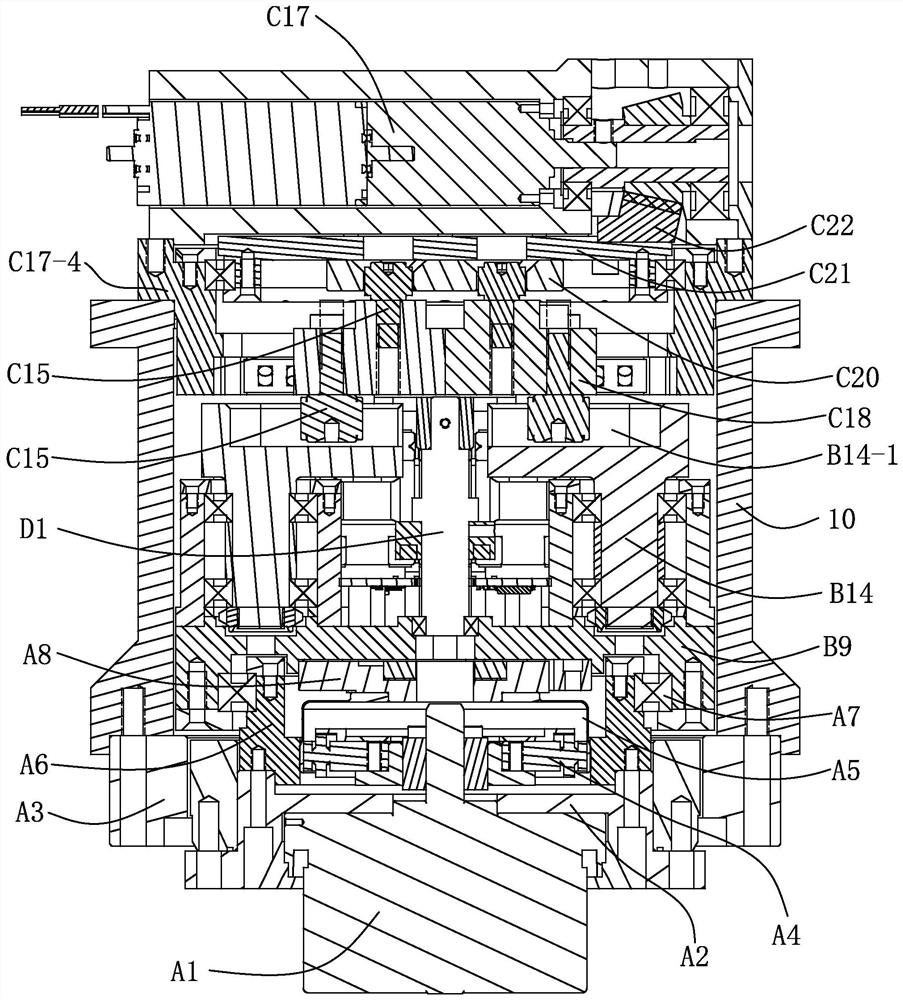

[0027] see Figure 1-Figure 6 As shown, a compact modular variable stiffness joint of this embodiment includes a joint housing 10, a main drive module A, an elastic module and a stiffness adjustment module C;

[0028] The elastic module includes a variable stiffness base B9, a linear spring module B13 and a lever assembly B14;

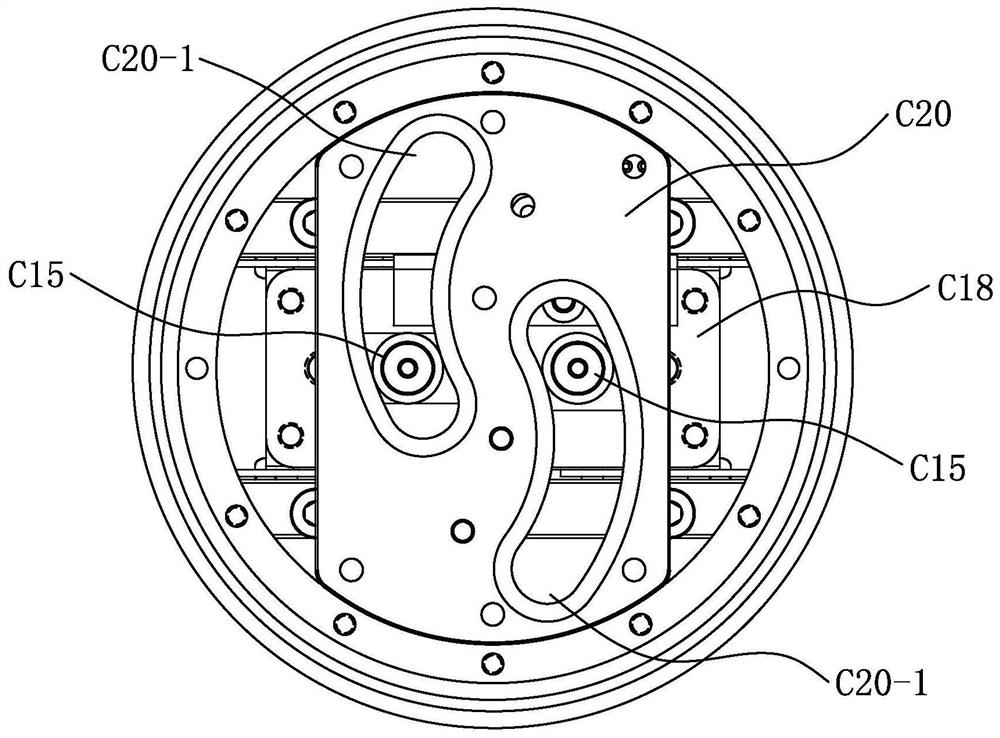

[0029] The main drive module A is arranged in the joint housing 10 and the two can rotate relatively, the elastic module is arranged in the joint housing 10, and the variable stiffness base B9 is driven to rotate by the output end of the main drive module A; the variable stiffness base B9 is rotatably provided with two axisymmetrically arranged lever assemblies B14, each lever assembly B14 has a sliding slot B14-1, one end of the sliding slot B14-1 is open, the other end is closed, and the two openings are oppositely arranged , the two outer walls of each chute B14-1 are respectively supported by a linear spring module B13, and the linear spring modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com