A compressor valve controller exhaust sheet feeding and conveying system and method

A valve controller and conveying system technology, which is applied in the field of compressor production, can solve the problems of poor assembly quality of the exhaust plate, achieve the effect of simple structure, prevent loosening or position misalignment, and improve the degree of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

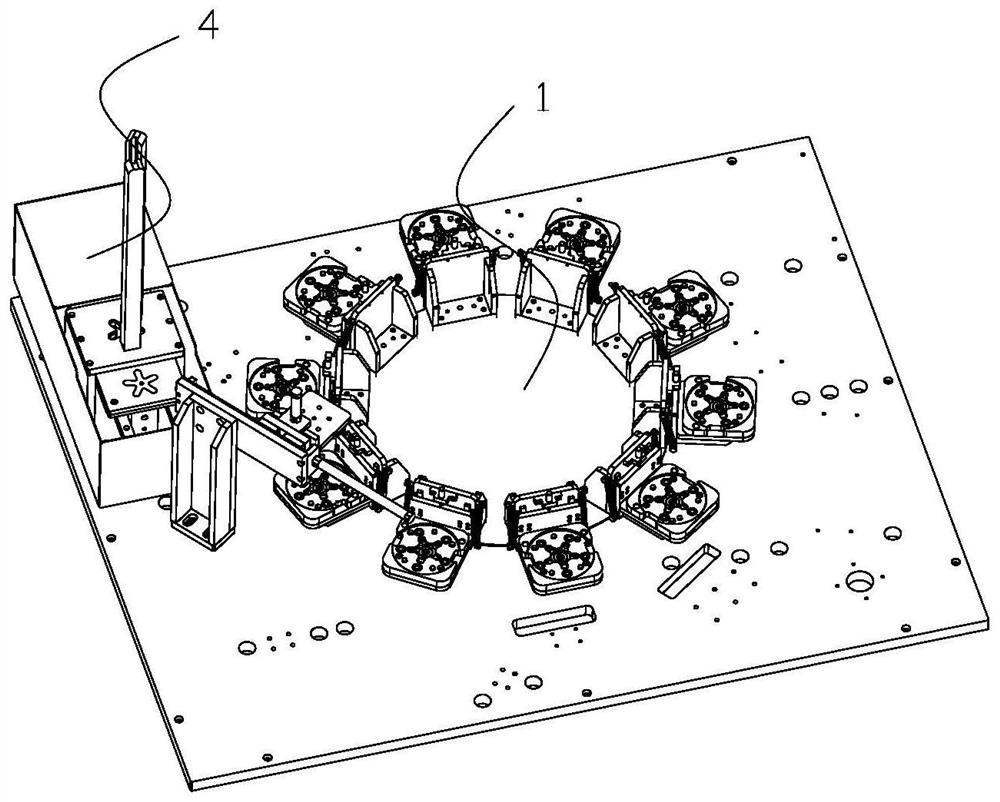

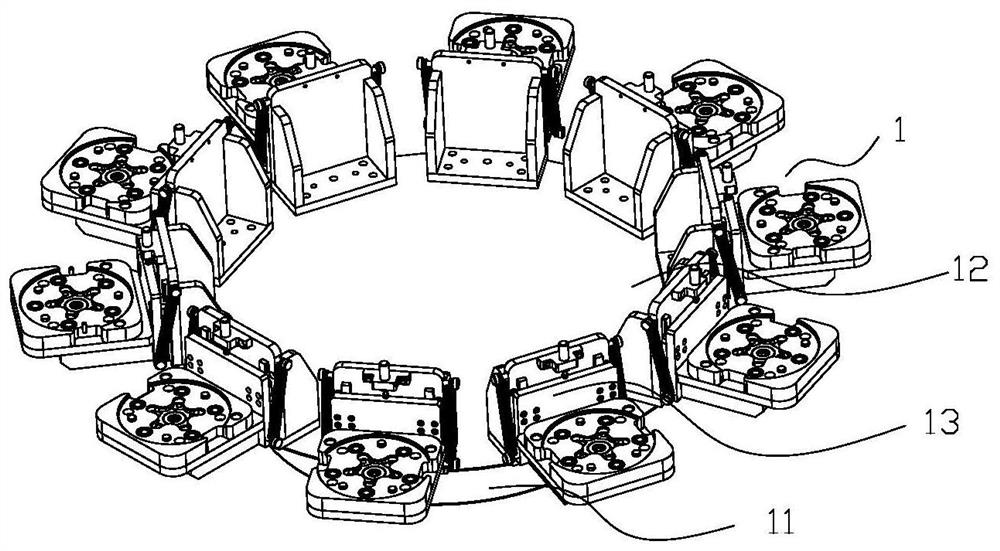

[0025] like figure 1 As shown, a compressor valve controller discharge plate feeding and conveying system includes an indexing plate device 1 and an exhaust plate feeding device 4; the exhaust plate feeding device 4 is located outside the indexing plate device 1; The air sheet feeding device 4 is used for feeding and transporting the exhaust sheet to the indexing disk device 1 , and the indexing disk device 1 is used for rotating and conveying the exhaust sheet.

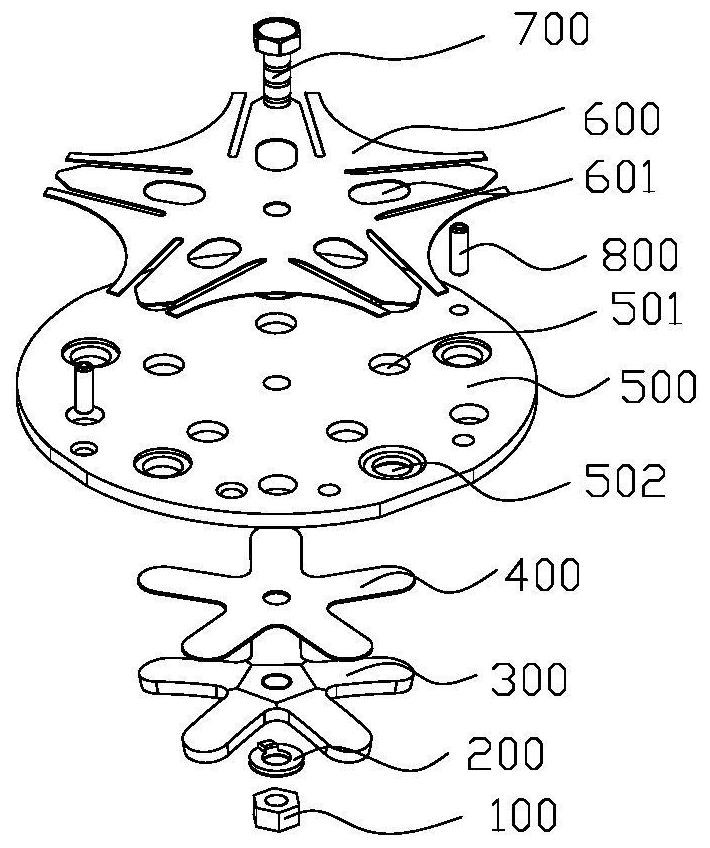

[0026] like figure 2As shown, the valve controller of the present invention includes a nut 100, a shrapnel 200, an exhaust sheet 300, an exhaust flap 400, a substrate 500, an air suction sheet 600 and a bolt 700 from bottom to top; The nut 100 is conveyed to the indexing plate device 1, the shrapnel 200 is conveyed to the top of the nut 100 by the shrapnel feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com