Tubular bus support fitting and power transmission system

A technology of tube nuts and fittings, which is applied in the fields of tube nut support fittings and power transmission systems, can solve problems such as poor reliability and poor elasticity of copper sheets, and achieve the effects of reliable pressure, good elasticity, and avoiding discharge phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

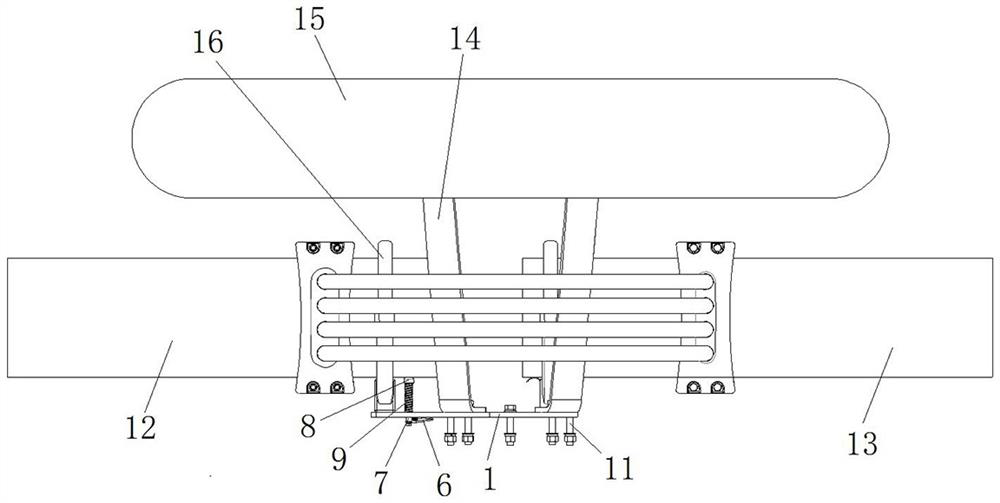

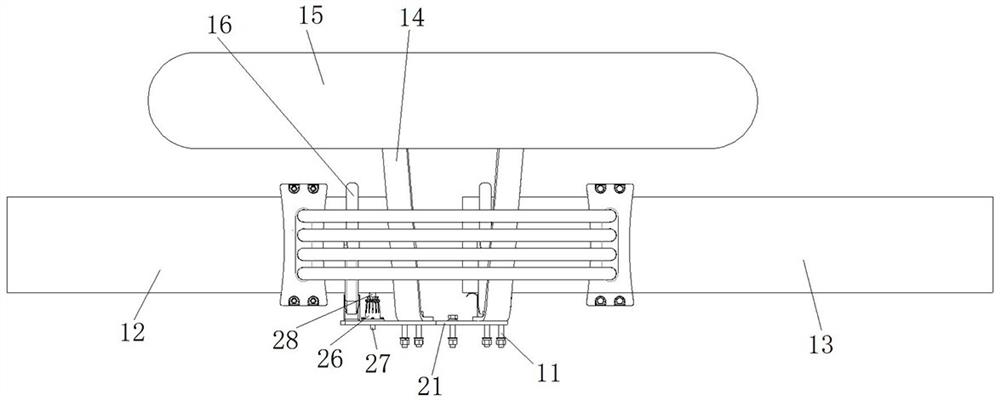

[0067] Such as figure 1 As shown, the power transmission system includes a first pipe mother 12 and a second pipe mother 13, the first pipe mother 12 and the second pipe mother 13 are arranged at intervals along the left and right directions, and there is a The pipe mother support fittings, the pipe mother support fittings include the flange plate 1, the flange plate 1 is provided with a plurality of fixing bolts 11, the flange plate 1 is fixed on the corresponding fixed foundation through the fixing bolts 11, and the flange plate 1 is also fixed There are support plates 14, the number of support plates 14 is multiple, and the upper ends of the multiple support plates 14 are connected to a pressure equalizing ring 15, and the pressure equalizing ring 15 is used to even out the electric field between the two tube mothers.

[0068] In this embodiment, pipe nut hoops 16 are respectively fixed on the left and right sides of the flange plate 1 , and the two pipe nut hoops 16 respec...

Embodiment 1

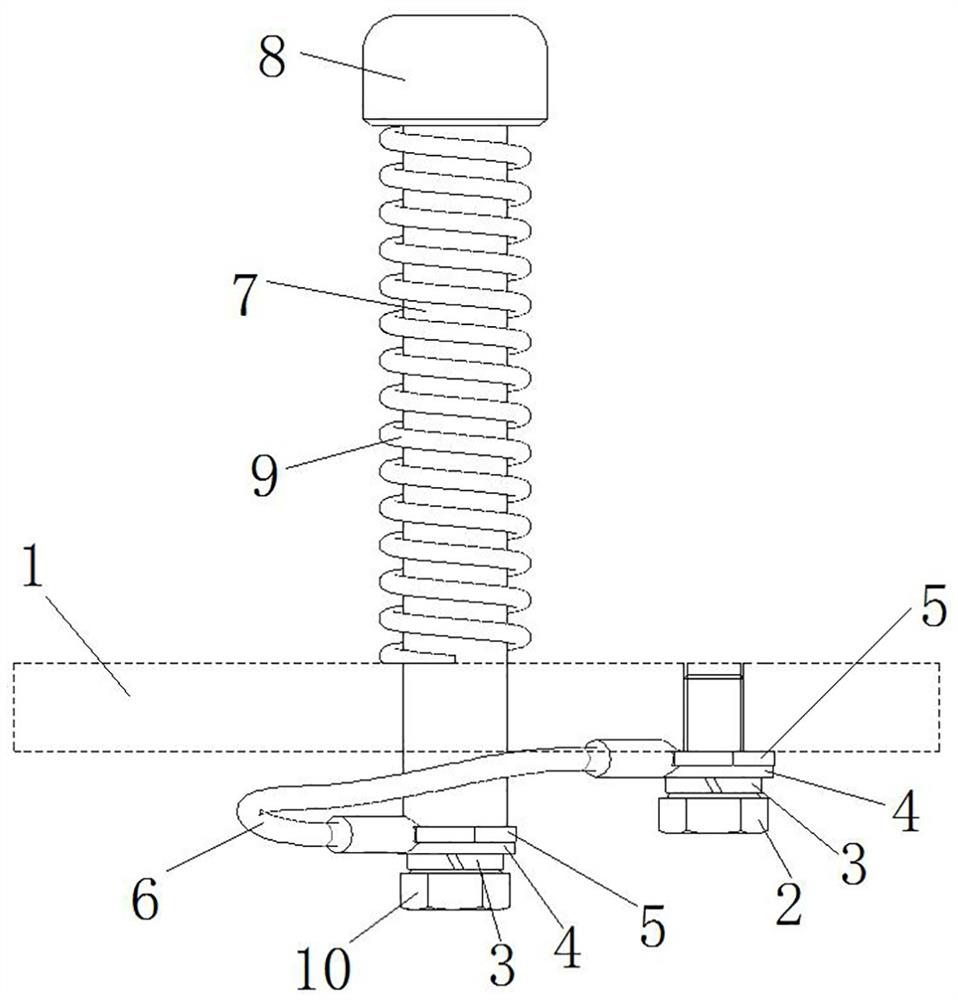

[0081] In Embodiment 1, the conductive rod and the flange plate 1 are conductively connected through the flexible wire 6, so that the first tube nut 12 and the flange plate 1 are reliably electrically connected when the conductive rod slides in the guide hole.

[0082] In this example, if Figure 3 to Figure 5 As shown, the upper side of the flange plate 21 is provided with a spring contact finger, the spring contact finger includes a base 30 and a contact finger arm 25, the base 30 is a flange structure, and the circumference of the base 30 is provided with a plurality of fixing holes, the flange plate 21 There are a plurality of threaded holes on the top, and the threaded holes correspond to the fixing holes one by one. Fixing screws 22 are installed in each fixing hole, and the fixing screws 22 are threadedly connected with the threaded holes to fix the base on the flange plate 21. A spring washer 23 and a washer 24 are sheathed on the screw 22 to ensure the stability of th...

specific Embodiment 3

[0087] In Embodiment 1, the conductive rod has a threaded rod section on which a fixing nut 10 is threaded, and the conductive piece 5 of the soft wire 6 is fixed on the conductive rod through the fixing nut 10 threaded on the threaded rod section. In this embodiment, a threaded hole is provided on the conductive rod, and a fixing bolt is threaded in the threaded hole, and the conductive piece of the flexible wire is fixed on the conductive rod through the fixing bolt threaded in the threaded hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com