Forming device for improving precision on basis of laser range finder

A laser range finder and forming device technology, applied in the field of warheads, can solve problems such as danger, poor coaxiality accuracy, and large crane stroke error, and achieve the effects of ensuring power, axial symmetry, and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

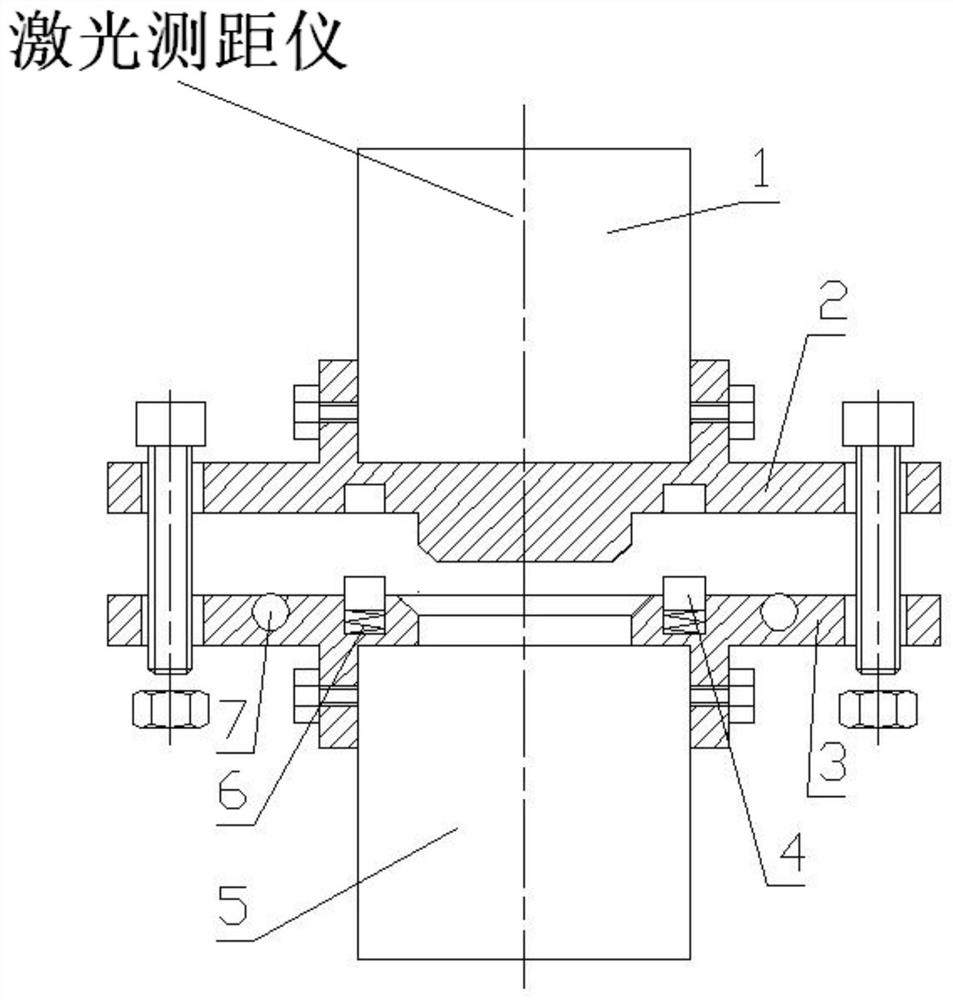

[0049] Such as figure 1 As shown, the molding device based on the laser range finder to improve the accuracy provided in this embodiment includes a laser range finder, an upper shell 1 and a lower shell 5, and is characterized in that it also includes an upper cover connecting frame 2, a lower cover Connecting frame 3, pin 4 and spring 6;

[0050] The upper shell 1 is a first cylinder, the first cylinder of the upper shell 1 is a body of revolution, the lower end surface of the first cylinder of the upper shell 1 is the first lower circular plane, and the first cylinder of the upper shell 1 The side surface of the cylinder is the first outer cylindrical surface;

[0051] The axis of the gyrator of the upper shell 1 is perpendicular to the ground, and the upper shell 1 is the warhead shell located at the upper end;

[0052] The loam cake connecting frame 2 is the second circular plate, the second circular plate of the loam cake connecting frame 2 is a revolving body, the uppe...

Embodiment 2

[0083] Such as figure 1 As shown, the molding device based on the laser range finder to improve the accuracy provided in this embodiment includes a laser range finder, an upper shell 1 and a lower shell 5, and is characterized in that it also includes an upper cover connecting frame 2, a lower cover Connecting frame 3, pin 4 and spring 6;

[0084] The upper shell 1 is a first cylinder, the first cylinder of the upper shell 1 is a body of revolution, the lower end surface of the first cylinder of the upper shell 1 is the first lower circular plane, and the first cylinder of the upper shell 1 The side surface of the cylinder is the first outer cylindrical surface;

[0085] The axis of the gyrator of the upper shell 1 is perpendicular to the ground, and the upper shell 1 is the warhead shell located at the upper end;

[0086] The loam cake connecting frame 2 is the second circular plate, the second circular plate of the loam cake connecting frame 2 is a revolving body, the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com