Cargo loading and unloading device and cargo loader

A technology for loading and unloading goods, which is applied to the arrangement of loading and unloading vehicles, lifting devices, vehicles used for freight transportation, etc. It can solve the problems of inapplicable medium and long-distance transportation, waste time by forklifts, and can only lift goods, etc., and achieve efficient unloading or transfer. , The effect of solving the gap problem of the telescopic arm and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

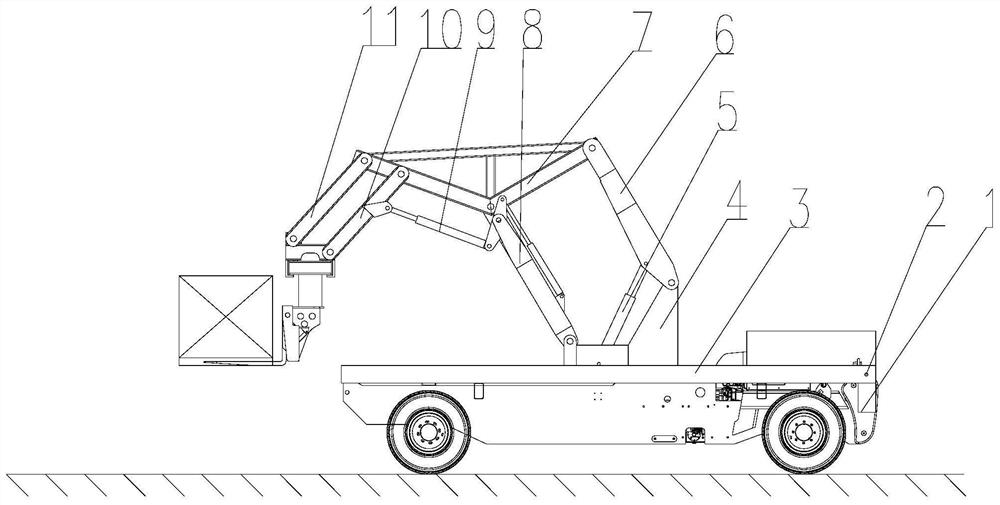

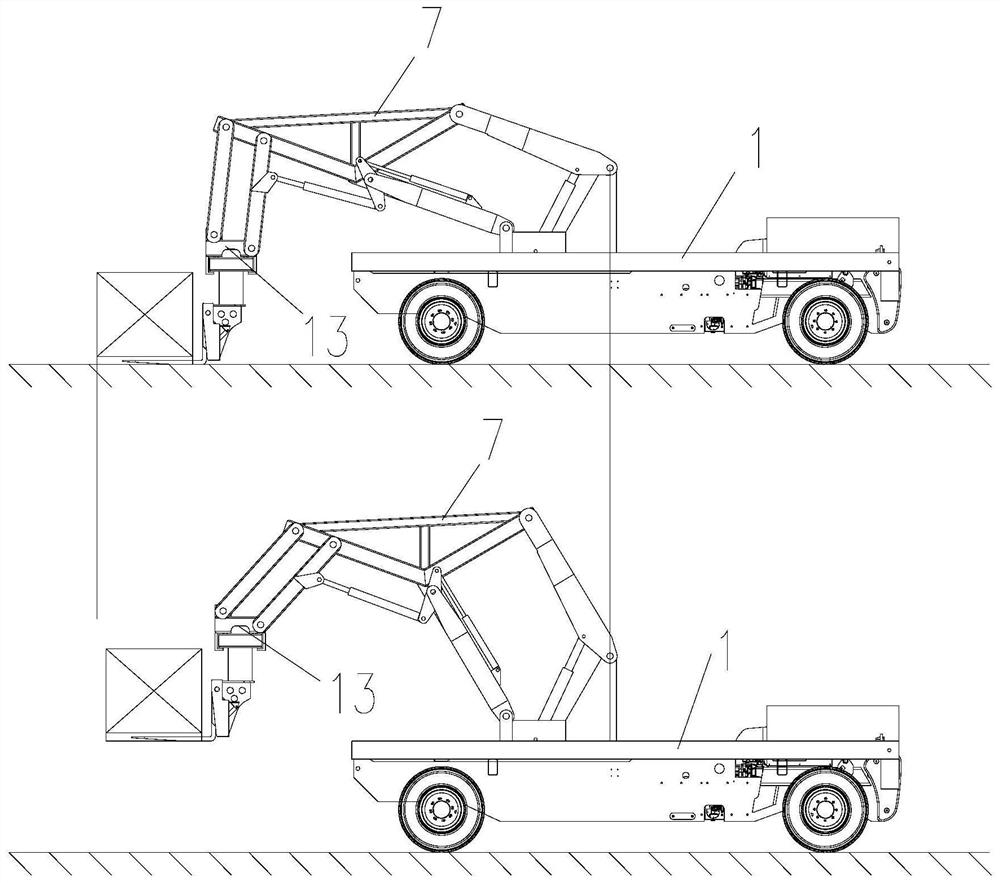

[0065] Such as figure 1 with figure 2 As shown, the cargo handling vehicle in this embodiment includes a vehicle body 1 and a cargo handling device installed on the vehicle body 1 .

[0066] The cargo handling device includes a support 4 slidingly arranged on the vehicle body 1, a transfer frame 7 and a translation frame 13 arranged at intervals along the front and rear directions of the vehicle body, and a cargo handling mechanism 15 arranged on the translation frame 13 for connecting with cargo . In this embodiment, the cargo handling mechanism 15 is specifically a fork tine assembly.

[0067] The lower end of the car body 1 is equipped with two wheel axles arranged at intervals along the front and rear directions of the car body 1, and two walking wheels arranged at intervals along the left and right directions of the car body 1 are installed on each wheel axle. Thereby car body 1 (chassis) provides transportation function, realizes that fork tine turns left and turns r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com