Insect-proof termite-proof protective long-life branch cable and manufacturing method thereof

A technology for branch cables and manufacturing methods, which is applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as easy access, reduce the service life of branch cables, and damage the joints, achieve high pressure and compression resistance, improve the scope of use, Scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

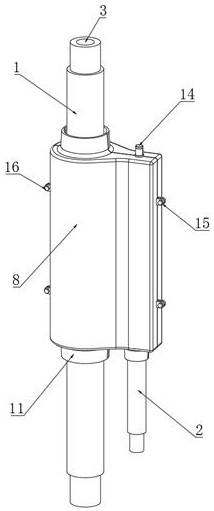

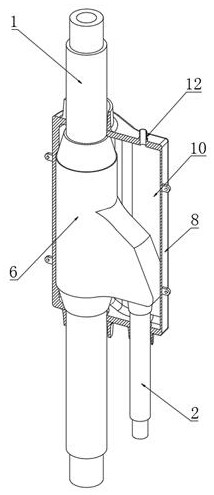

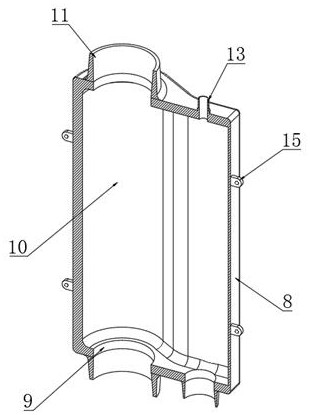

[0045] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a protective long-life branch cable for preventing insects and ants, including a main cable sheath 1, and the side of the main cable sheath 1 is connected with a branch cable sheath 2 in a Y shape. Both the cable sheath 1 and the middle part of the inner side of the branch cable sheath 2 are connected with a connecting conductor 3, and the connecting conductor 3 inside the branch cable sheath 2 and the connecting conductor 3 inside the main cable sheath 1 are also connected in a Y shape. The outer side of the conductor 3 is covered with an insulating protective layer 4, and the outer side of the insulating protective layer 4 is tightly wound with a metal insulating belt 5, and the outer side of the metal insulating belt 5 is located at the junction of the main cable sheath 1 and the branch cable sheath 2 There is a wrapping layer 6 tightly wound around it, and the wrapping layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com