Rapid detection equipment and detection method for water-sensitive test paper

A technology of testing equipment and test strips, which is applied in the direction of analyzing materials through chemical reactions and observing the influence of chemical indicators on materials, etc., which can solve the problems of inability to achieve rapid detection, data acquisition, waste of human resources, detection errors, Problems such as deviation of test results can be achieved to achieve high-efficiency testing operations, reduce testing costs, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

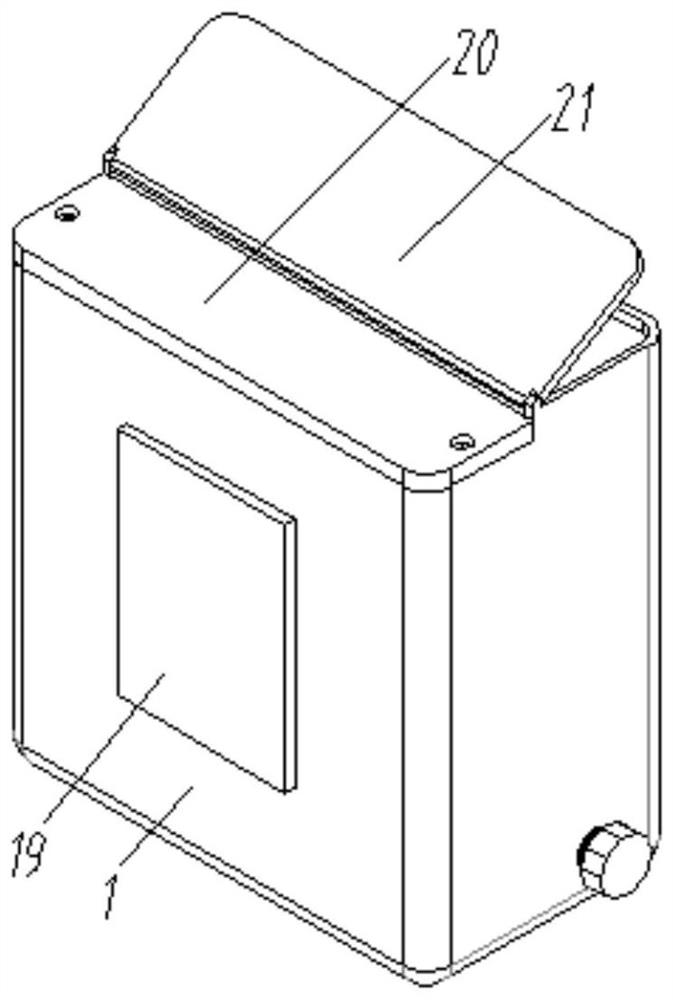

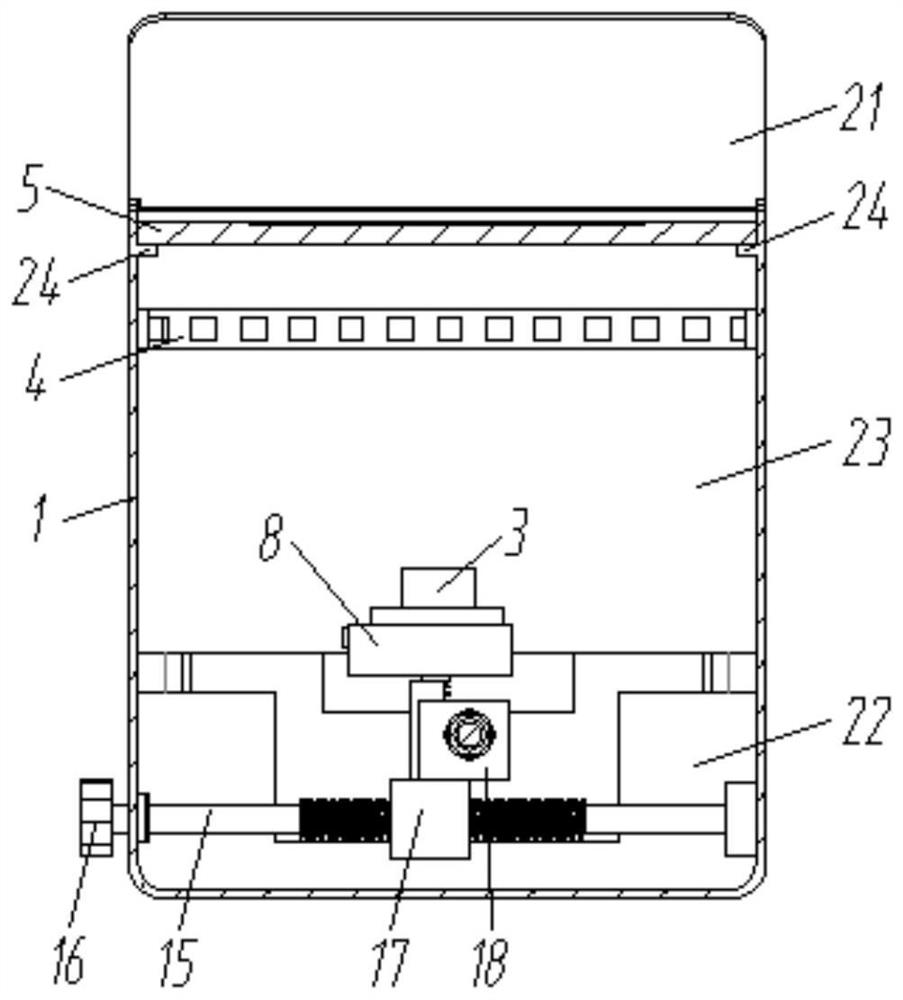

[0045] On the basis of the above structure, in this embodiment, a gear 6 and a rack 7 are installed in the outer box 1 , the rack 7 is arranged vertically, and the upper end of the rack 7 is connected to the image capturing device 3 ; the gear 6 can be positioned and rotated horizontally It is on one side of the rack 7 and meshes with the rack 7 ; the gear 6 rotates and drives the image acquisition device 3 to move up and down through the rack 7 . When the position of the image capturing device 3 in the vertical direction needs to be adjusted, the gear 6 is rotated in a manner that those skilled in the art can think of, and the gear 6 uses the meshing force between the gear 6 and the rack 7 to drive the rack 7 to move up and down, Therefore, the image capturing device 3 is driven to move up and down, thereby adjusting the position of the image capturing device 3 in the vertical direction, the structure is simple, and the adjustment is convenient and quick.

Embodiment 2

[0047] On the basis of the first embodiment, in this embodiment, the upper end of the rack 7 is fixedly installed with a carrier box 8 for carrying the image capture device 3, and the carrier box 8 is fixed to the upper end of the rack 7 by welding or bolting; The image capturing device 3 is fixed in the carrying box 8 by bolts. Here, the image capture device 3 is carried by the carrier box 8 , which is convenient for installation and can increase the stability of the image capture device 3 in the moving process.

Embodiment 3

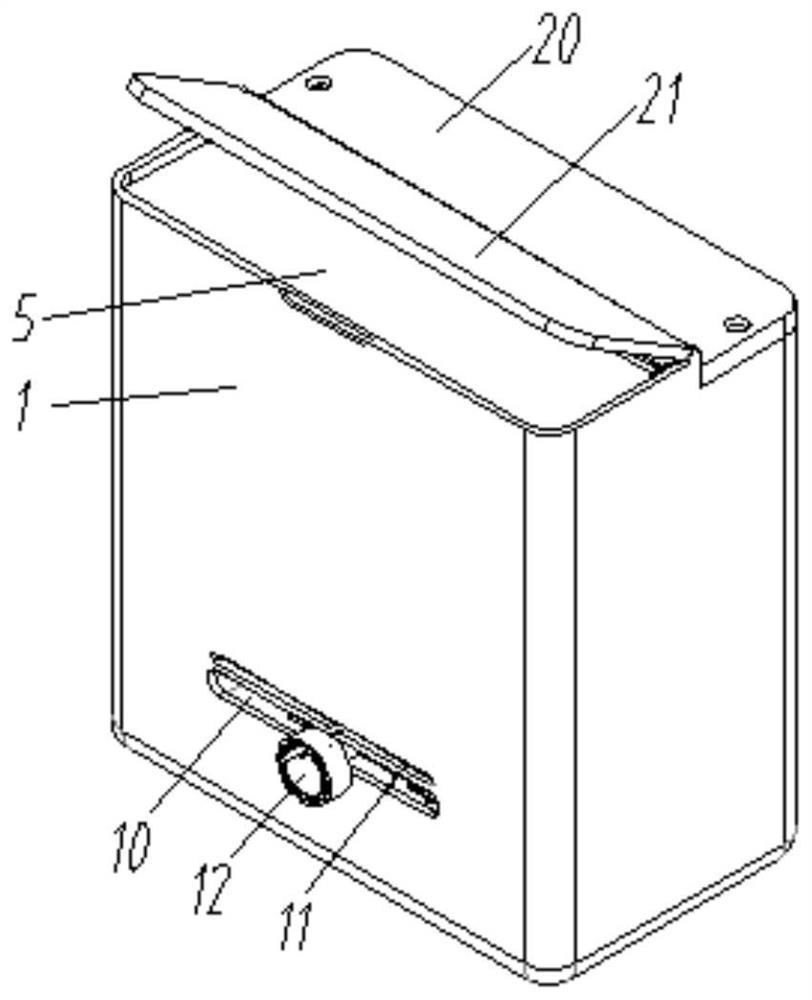

[0049] On the basis of the first embodiment, in this embodiment, a gear shaft 9 is installed in the outer case 1 to be positioned and rotated horizontally, and the gear 6 is coaxially fixed and sleeved on the gear shaft by means that those skilled in the art can think of. 9, a bar-shaped opening 10 is horizontally provided on one side of the outer case 1; During adjustment, the gear shaft 9 is rotated to drive the gear 6 to rotate, so as to use the meshing force between the gear 6 and the rack 7 to drive the rack 7 to move up and down, thereby driving the image acquisition device. 3 Move up and down to adjust the position of the image capture device 3 in the vertical direction; in addition, move the gear shaft 9 horizontally to drive the gear 6, the rack 7 and the image capture device 3 to move in the horizontal direction to adjust the image capture device 3 The position in the horizontal direction is suitable for water-sensitive test strips of different sizes and has a wide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com