Novel mounting structure of fabricated wall surface closing-in strip

A technology of installation structure and closing strip, applied in the direction of building structure, construction, etc., can solve the problems of unenvironmental protection, limited wall application range, poor process quality, etc., to achieve good installation effect, better installation quality, and improved connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

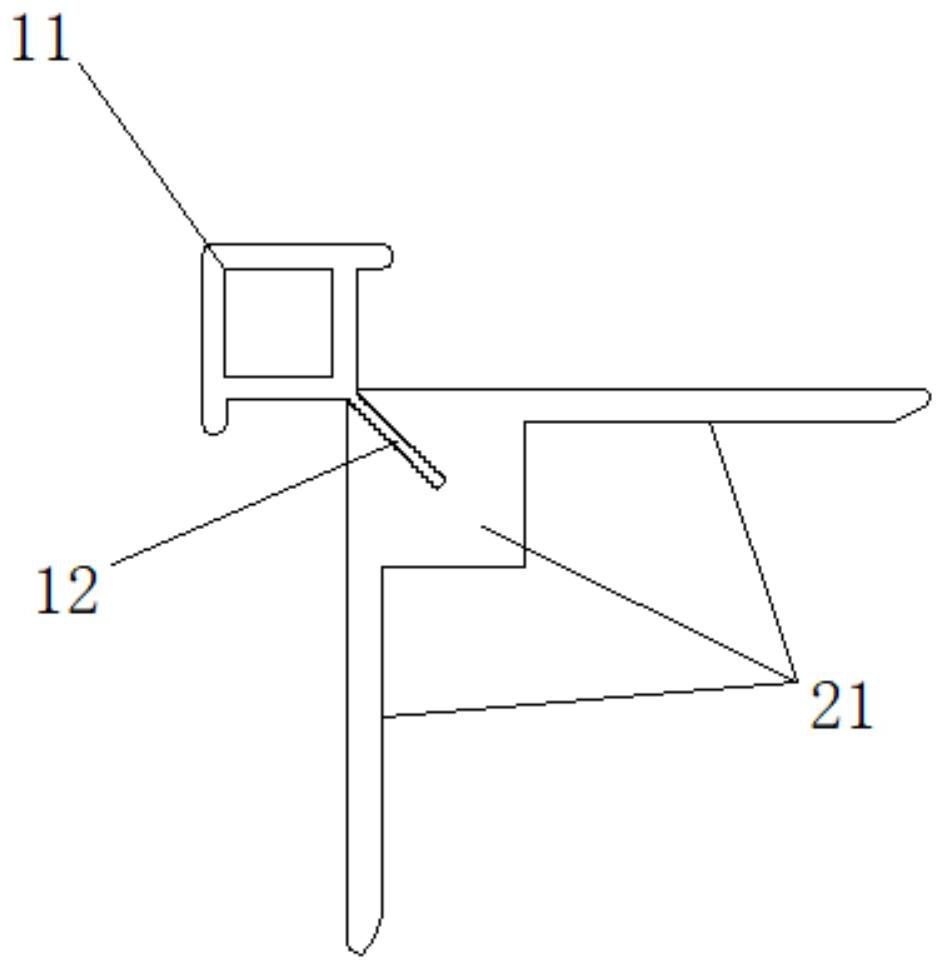

[0043] see Figure 1 to Figure 4 , Figure 5 as well as Figure 9 , the figure shows the installation structure of a new type of prefabricated wall closing strip provided by Embodiment 1 of the present invention, which mainly includes: fixed closing strip 1, which includes decorative lines 11 and connecting strips 12; fixed base 2, which includes The fixing frame 21 and the connecting groove 22 arranged on the fixing frame 21; the connecting bar 12 is inserted in the connecting groove 22; the fixing base 2 is arranged at the male corner position, the female corner position or the middle seam position of the base wall 3; the wallboard 4 , which are arranged on both sides of the decorative line 11 .

[0044] The installation structure of a new type of prefabricated wall closing strip provided in this embodiment mainly includes a fixed closing strip 1 and a fixed base 2, wherein the fixed closing strip 1 includes a decorative line 11 and a connecting strip 12, and the fixed bas...

Embodiment 2

[0052] see Figure 3 to Figure 4 , Figure 7 to Figure 8 as well as Figure 11 to Figure 12 , the figure shows the installation structure of a new type of prefabricated wall finish provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: Both the outer wall of the connecting bar 12 and the inner wall of the connecting groove 22 are provided with connecting teeth 23; the connecting teeth 23 are in a continuous "V" shape. Through the arrangement of the above structure, the connection force between the connection bar 12 and the connection groove 22 can be improved, and the installation quality can be further improved.

Embodiment 3

[0054] see Figure 1 to Figure 4, the figure shows the installation structure of a new type of prefabricated wall finish provided by the third embodiment of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: When the fixed base 2 is arranged at the external angle position of the base wall body 3, the fixed frame 21 includes a connecting plate 211 and a positioning plate 212 arranged on the adjacent two sides of the first connecting plate 211, and the two positioning plates 212 are perpendicular; the connecting groove 22 is located at at the outer corner of the connecting plate 211. Through the setting of the above structure, the external corner position of the base wall 3 can be quickly closed, and the appearance is beautiful and the installation quality is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com