Preparation method of supercapacitor electrode material vanadium trioxide/carbon

A technology of vanadium trioxide and supercapacitor, applied in the field of electrochemical energy storage, can solve problems such as high working voltage, and achieve the effect of simple preparation process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 400 mg glucose, add a mixed solution of 40 mL deionized water and 10 mL isopropanol, stir until dissolved, and stir at 600 rpm.

[0023] (2) Weigh 40 mg of vanadyl acetylacetonate into the glucose solution obtained in step (1) and stir until dissolved at a stirring rate of 600 rpm.

[0024] (3) Transfer the solution obtained in step (2) to a 100 mL reactor, and place it in a constant temperature drying oven at 170 °C for 24 hours.

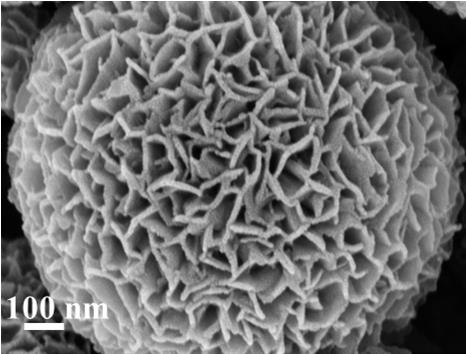

[0025] (4) Washed with alcohol, centrifuged three times, dried under vacuum for 12 h, and finally heat-treated in air atmosphere to obtain V 2 o 3 / C hollow nanosphere material. The centrifugal speed is 5000 rpm, the drying temperature is 60 °C, the drying time is 12 h, the heat treatment temperature is 500 °C, the heat treatment time is 1.5 h, and the heating rate is 2 °C / min.

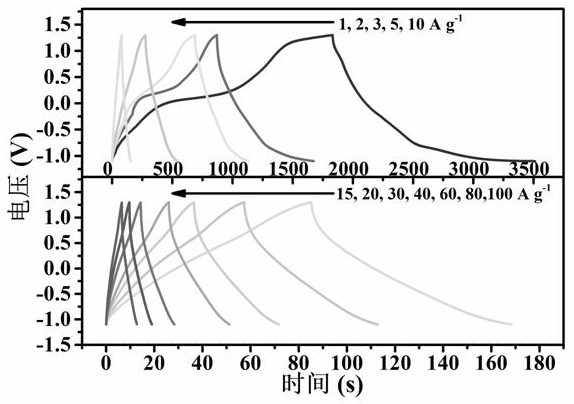

[0026] (5) With 1 M Na 2 SO 4 As the electrolyte, the V obtained in step (4) 2 o 3 / C hollow nanosphere electrodes as electrodes and cellulose acet...

Embodiment 2

[0028] (1) Weigh 500 mg of glucose, add a mixed solution of 40 mL of deionized water and 10 mL of isopropanol, stir until dissolved, and the stirring speed is 600 rpm.

[0029] (2) Weigh 50 mg of vanadyl acetylacetonate into the glucose solution obtained in step (1) and stir until dissolved at a stirring rate of 600 rpm.

[0030] (3) Transfer the solution obtained in step (2) to a 100 mL reactor, and place it in a constant temperature drying oven at 160 °C for 20 hours.

[0031] (4) Washed with alcohol, centrifuged three times, dried under vacuum for 12 hours, and finally heat-treated in air atmosphere to obtain V 2 o 3 / C hollow nanosphere material. The centrifugal speed is 5000 rpm, the drying temperature is 60 °C, the drying time is 12 h, the heat treatment temperature is 500 °C, the heat treatment time is 1.5 h, and the heating rate is 2 °C / min.

[0032] (5) With 1 M Na 2 SO 4 As the electrolyte, the V obtained in step (4) 2 o 3 / C hollow nanosphere electrodes as el...

Embodiment 3

[0034] (1) Weigh 600 mg of glucose, add a mixed solution of 40 mL of deionized water and 10 mL of isopropanol, stir until dissolved, and the stirring speed is 600 rpm.

[0035] (2) Weigh 60 mg of vanadyl acetylacetonate into the glucose solution obtained in step (1) and stir until dissolved at a stirring rate of 600 rpm.

[0036] (3) Transfer the solution obtained in step (2) to a 100 mL reactor, and place it in a constant temperature drying oven at 180 °C for 24 hours.

[0037] (4) Washed with alcohol, centrifuged three times, dried under vacuum for 12 h, and finally heat-treated in air atmosphere to obtain V 2 o 3 / C hollow nanosphere material. The centrifugal speed is 5000 rpm, the drying temperature is 60 °C, the drying time is 12 h, the heat treatment temperature is 500 °C, the heat treatment time is 1.5 h, and the heating rate is 2 °C / min.

[0038] (5) With 1 M Na 2 SO 4 As the electrolyte, the V obtained in step (4) 2 o 3 / C hollow nanosphere electrodes as electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com