Spliced tobacco stem box frame and using method

A splicing, tobacco stem technology, applied in rigid containers, containers, packaging, etc., can solve the problems of cigarette quality influence, easy deformation, easy puncture, etc., to achieve cigarette quality and hygiene assurance, strengthen strength, and avoid leakage of stems and materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

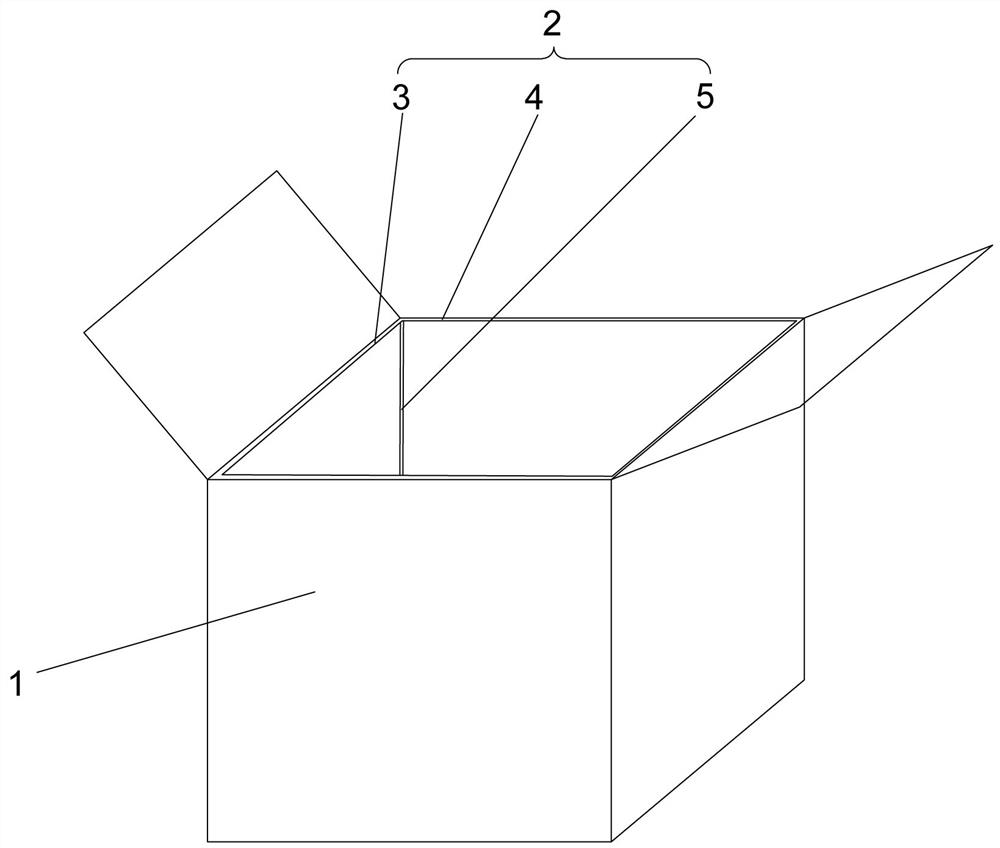

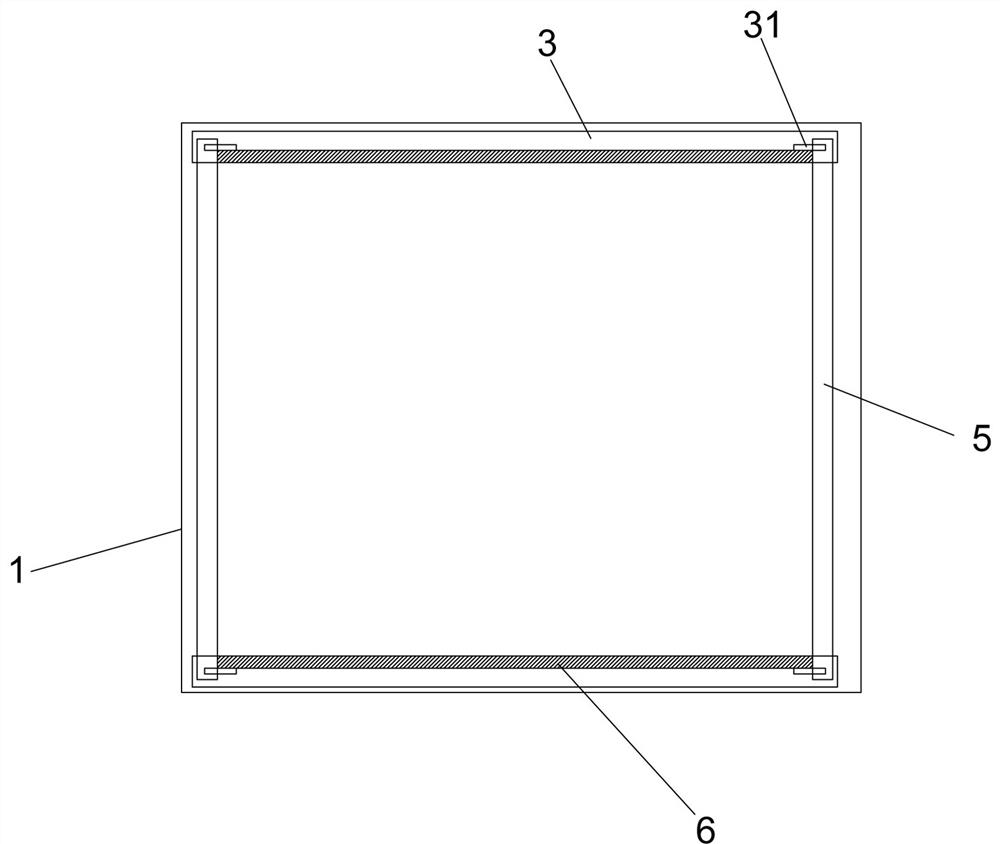

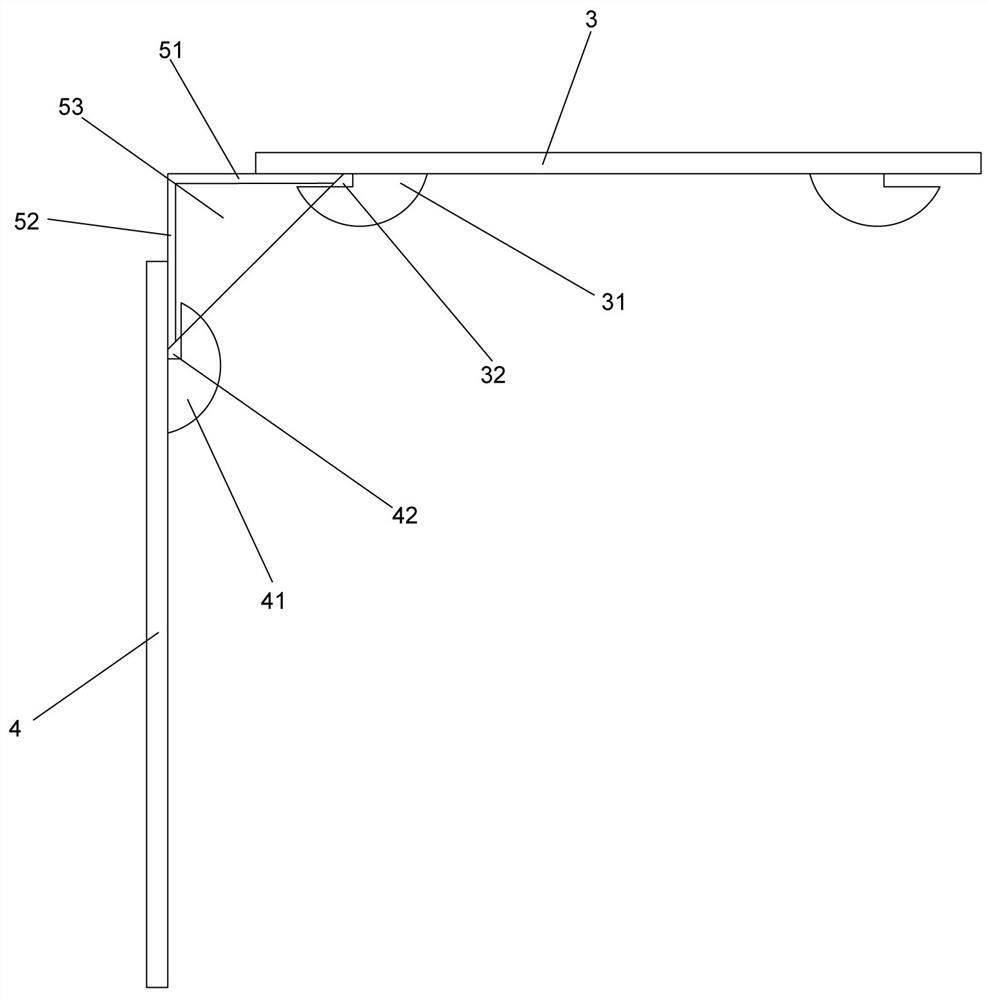

[0038] Embodiment one: if Figures 1 to 5 As shown, it is only one of the embodiments of the present invention, a spliced tobacco stem box frame, including a box body 1 and a frame body 2 arranged in the box body 1, and the frame body 2 includes a first column 3. The second column 4 and the third column 5, the first column 3 is provided with a first block 31, and a first card slot 32 is opened between the first block 31 and the first column 3 , the second column 4 is provided with a second block 41, a second slot 42 is opened between the second block 41 and the second column 4, and the third column 5 includes a first plane 51 and a second plane 52 perpendicular to the first plane 51, at least a part of the first plane 51 is located in the first slot 32, and at least a part of the second plane 52 is located in the second Inside the card slot 42 , a backing plate 6 is also arranged inside the box body 1 .

[0039] In the present invention, the frame body 2 is arranged inside...

Embodiment 2

[0045] Embodiment two, still as Figures 1 to 5 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in a spliced tobacco stem box frame of the present invention, the box body 1 also has other shapes, such as triangular prism, pentagonal prism, upper Special-shaped hexahedron with narrow bottom and wide bottom, etc. If the box body 1 is a triangular prism, a pentagonal prism or other prisms, then the number of the third column 5 will be correspondingly changed to 3, 5 and other numbers, and the number of the third column 5 is equal to the prism of the box body 1 number; if the box body 1 is a special-shaped hexahedron with a narrow top and a wide bottom or a narrow top and a narrow bottom, the third column 5 is obliquely set at this moment, still sticking to the side of the inclined setting of the box body 1, and the first column at the top of the box body 1 The column 3 and the second column 4 are respectively different in len...

Embodiment 3

[0052] Embodiment three, such as Image 6 As shown, the present invention also provides a method for using the spliced stem box frame in the above embodiment, including the following steps:

[0053] S1: Vertically place the third column at each corner of the box;

[0054] S2: The first card slot formed by the first column at the bottom of the box and the first block on the first column and the second card slot formed by the second column and the second card block on the second column are respectively locked to the third at the first and second planes at the base of the column;

[0055] S3: Lay the bottom backing plate on the first column and the second column at the bottom of the box;

[0056] S4: Put the tobacco stems in the box, and lay the upper backing plate on the top of the tobacco stems;

[0057] S5: The first slot formed by the first column on the top of the box and the first block on the first column and the second slot formed by the second column and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com