Transient voltage suppression diode structure and manufacturing method thereof

A technology of transient voltage suppression and manufacturing method, applied in diodes, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor surge current capability, and achieve the effect of reducing size and improving IPP surge current capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

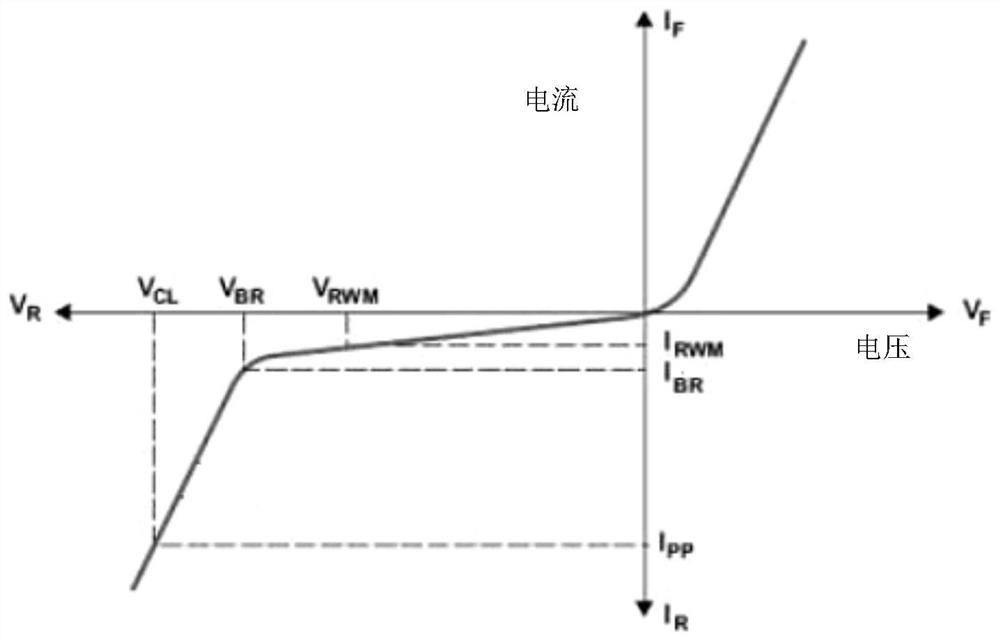

[0049] The inventor researched and analyzed the reverse use process of the unidirectional transient voltage suppression diode, and found that most of the I PPThe surge current flows from the N-type layer to the P-type layer at the corners of the PN junction. This causes the current density in the middle and corners of the PN junction to be unequal, causing anti-I PP The surge current capability is relatively poor.

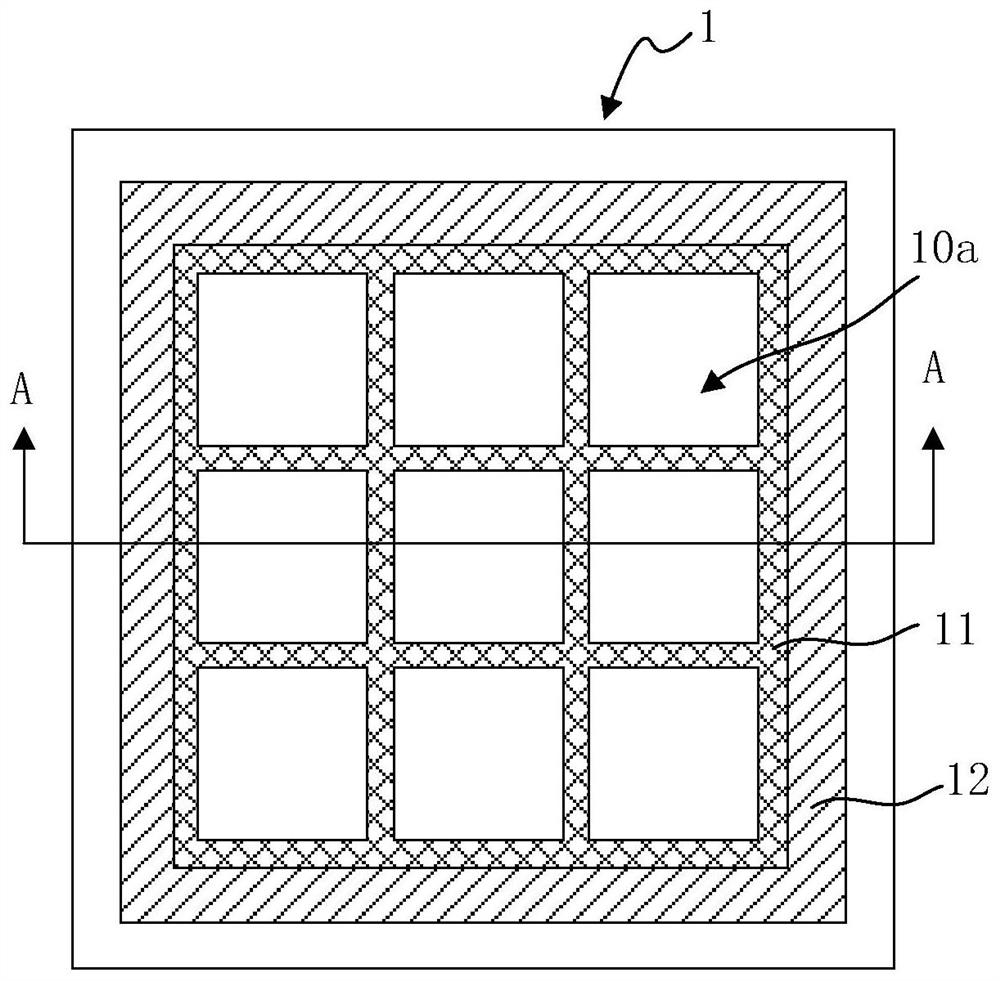

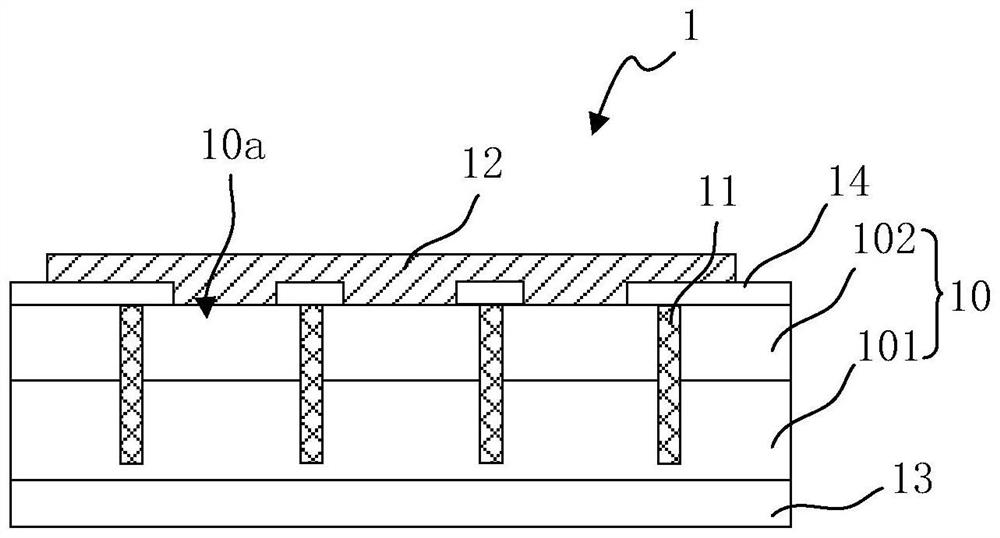

[0050] Based on the above analysis, the present invention proposes: a plurality of isolation rings are arranged in the semiconductor stack, and the semiconductor stack is separated into a plurality of stack units by the plurality of isolation rings; the first electrode and the second electrode are respectively formed on the upper surface and the lower surface of the semiconductor stack. Two electrodes, the first electrode and the second electrode are continuously distributed in each lamination unit. In other words, each stack unit corresponds to a transient volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap