Aircraft skin seam detection method based on large-scale point cloud

A technology for aircraft skins and detection methods, which is applied in measurement devices, 3D modeling, computer parts, etc., can solve the problems of large errors, low efficiency, and high requirements for manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

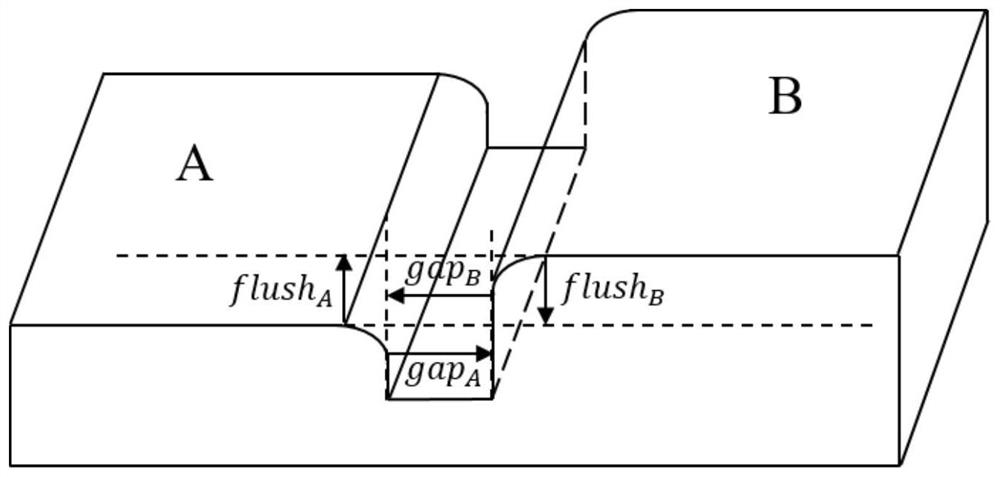

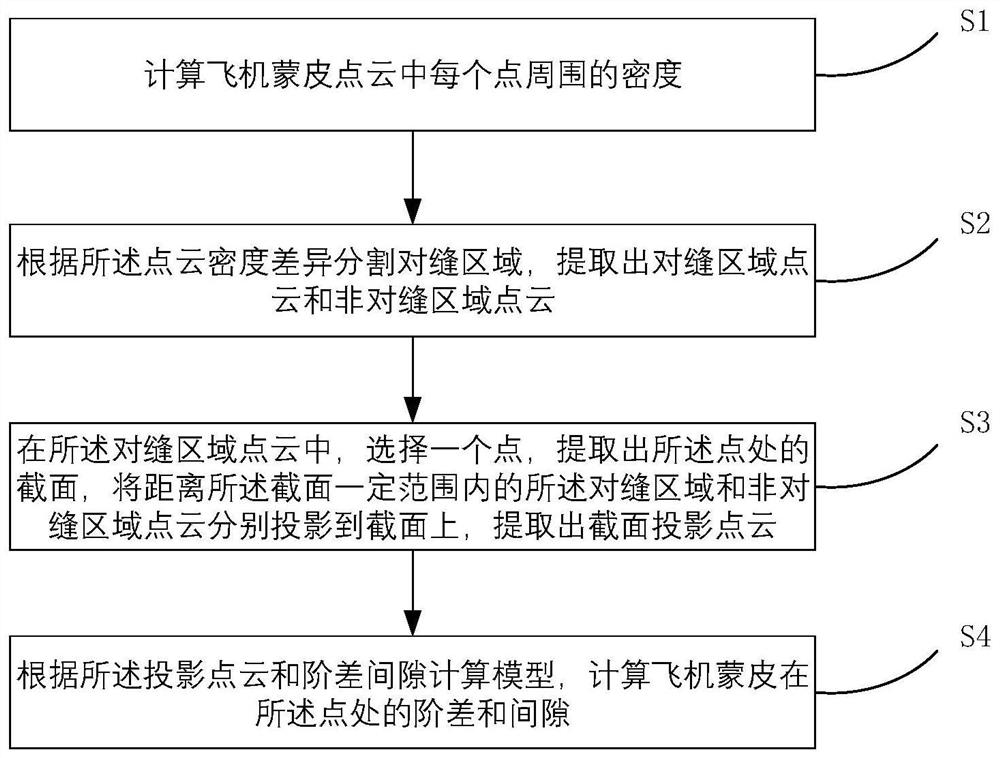

[0064] In order to solve the problem that it is difficult to automatically measure aircraft skin step difference and gap in the prior art, the present invention provides a large-scale point cloud based aircraft skin seam detection method, figure 1 shows an alternative model structure for aircraft skinning, figure 2 An alternative flowchart showing the algorithm, as in figure 2 As shown, the method includes:

[0065] Step 1, calculate the point cloud density around each point in the aircraft skin point cloud;

[0066] Step 2. Segment the joint area according to the calculated point cloud density difference, and extract the point cloud of the joint area and the point cloud of the non-joint area;

[0067] Step 3: Select a point in the point cloud of the joint area, extract the cross section at the point, project the point clouds of the joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com