Sealing structure of horizontal rotary pyrolysis kiln

A sealed structure, pyrolysis kiln technology, used in rotary drum furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of short service life, air leakage of flexible connectors, short service life of flexible connectors, etc. performance, improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

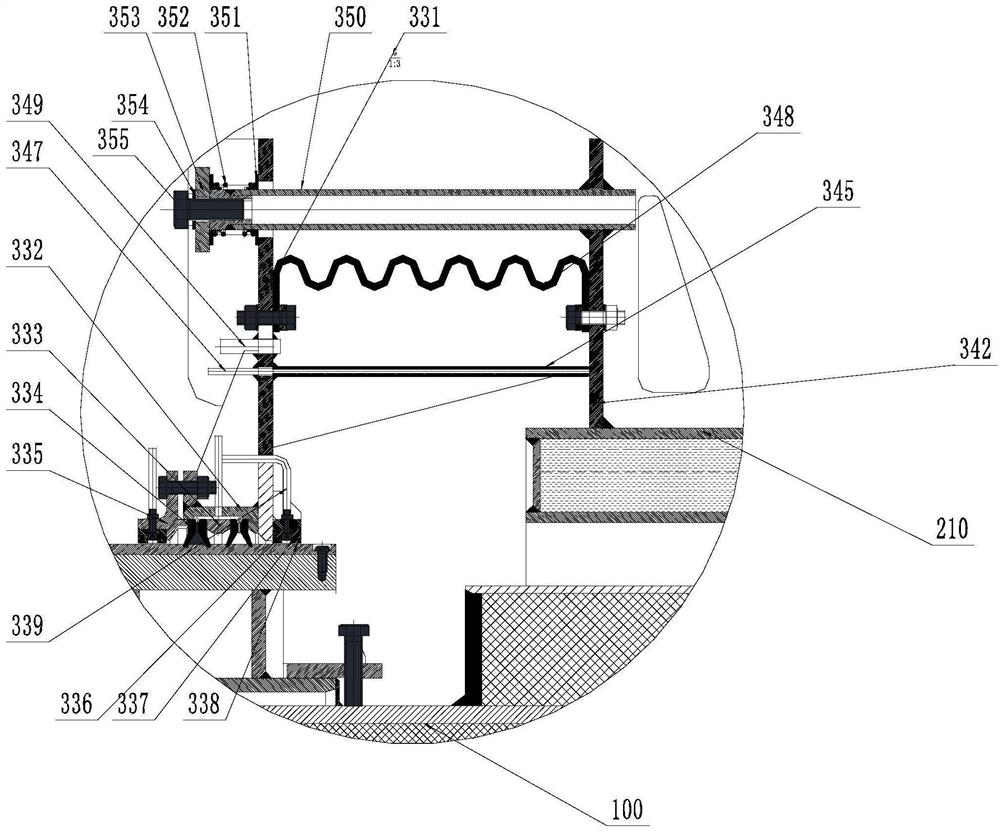

[0051] see figure 1 and figure 2 , this embodiment provides a sealing structure for a horizontal rotary pyrolysis kiln. It includes: a horizontal rotary pyrolysis kiln main body 100 , a kiln tail 110 , a kiln tail cover 200 , and a rotary sealing structure 300 . Wherein, a discharge port 400 for solid material after pyrolysis is provided under the kiln tail cover 200, and a pyrolysis gas outlet 500 is provided at the center of the end face of the kiln tail. The heat preservation layer 120 of the horizontal rotary pyrolysis kiln tail cover is arranged on the outer periphery of the kiln tail cover 200 . A kiln tail outer insulation layer 310 is arranged on the outer periphery of the kiln tail 110 .

[0052] refer to figure 1 As shown, a support frame 320 is fixedly arranged on the outer periphery of the kiln tail 110 , and the support frame 320 rotates synchronously with the kiln tail 110 . The support frame 320 includes the support frame inner ring 321 arranged on the out...

Embodiment 2

[0079] refer to image 3 with Figure 4 As shown, the difference from Embodiment 1 is that Embodiment 2 is based on Embodiment 1. In order to shorten the axial length of the movable heat-insulation sealing ring 345 and the flexible sealing mechanism 348, respectively in the vertical ring of the rotary sealing mechanism A grooved ring is added between the plate one 331 and the kiln tail vertical annular plate two 342.

[0080] Correspondingly, a left annular groove 340, a left packing 341, a right annular groove 343, a right packing 344 and a friction ring 346 of the movable heat insulation sealing ring are added, and the left annular groove 340 is fixed to the vertical annular plate 331 of the rotary sealing mechanism. One end of the left annular groove 340 away from the vertical annular plate one 331 of the rotary sealing mechanism is fixedly connected with a flexible sealing mechanism 348 .

[0081] A right annular groove 343 is connected to the end of the kiln tail vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com