Superconducting maglev train

A maglev train and superconducting technology, applied in the field of rail transportation, can solve the problems of low integration of guidance and drive, high cost, etc., and achieve the effect of improving the utilization rate of magnetic energy and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

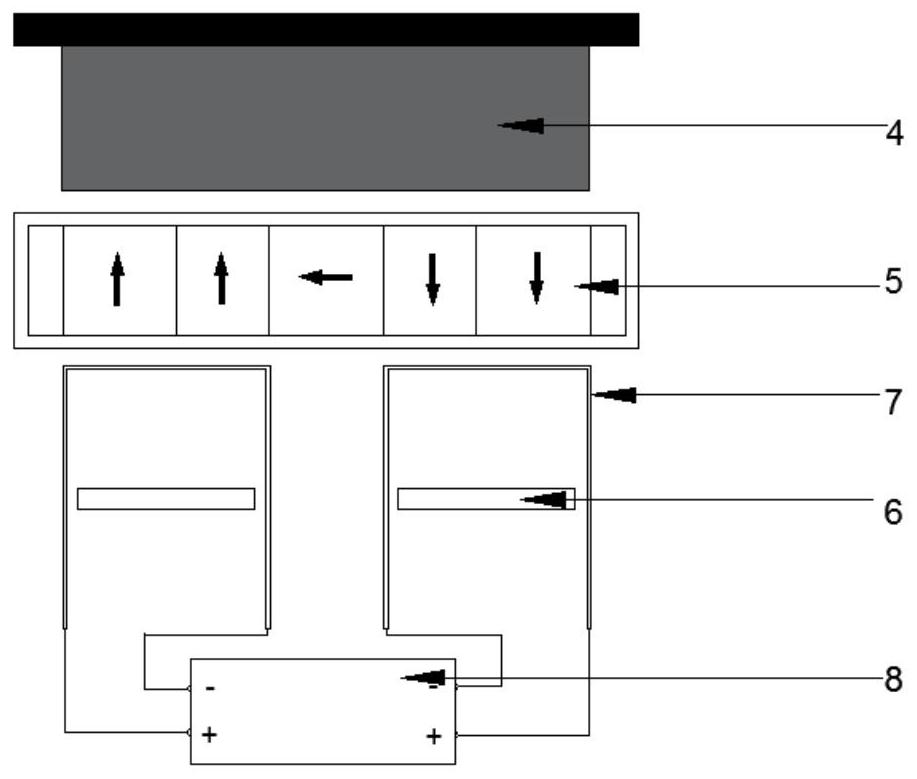

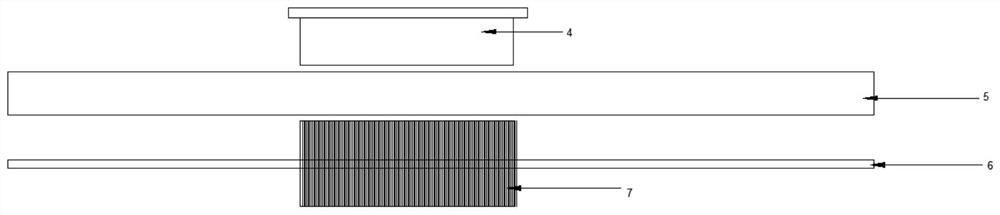

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present embodiment provides a superconducting maglev train, which includes a vehicle frame 1, an arm 3, a Dewar 4, a superconductor, a permanent magnet track 5, an iron core 6, a coil 7 and a power supply 8 . The arm 3 is arranged at the bottom of the frame 1; the Dewar 4 is arranged at the bottom of the frame 1; the superconductor is arranged in the Dewar 4; the permanent magnet track 5 is arranged in the Below the Dewar 4; the iron core 6 is arranged below the permanent magnet track 5; the coil 7 is sleeved on the iron core 6; end connected.

[0023] Compared with the traditional high-temperature superconducting maglev train, this implementation case abandons the traditional stator winding structure laid along the line, and the present invention realizes the levitation-guiding function by utilizing the interaction between the superconductor and the upper surface magnetic field of the permanent ma...

Embodiment 2

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present embodiment provides a superconducting maglev train, which includes a vehicle frame 1, an arm 3, a Dewar 4, a superconductor, a permanent magnet track 5, an iron core 6, a coil 7 and a power supply 8 . The arm 3 is arranged at the bottom of the frame 1; the Dewar 4 is arranged at the bottom of the frame 1; the superconductor is arranged in the Dewar 4; the permanent magnet track 5 is arranged in the Below the Dewar 4; the iron core 6 is arranged below the permanent magnet track 5; the coil 7 is sleeved on the iron core 6; end connected.

[0026] Optionally, the superconducting maglev train further includes a track body 2 on which the permanent magnet track 5 is arranged.

[0027] In this embodiment, the basic technical effect produced by it is the same as that of the foregoing embodiment 1. For a brief description, this embodiment only illustrates different technical effects: the supercondu...

Embodiment 3

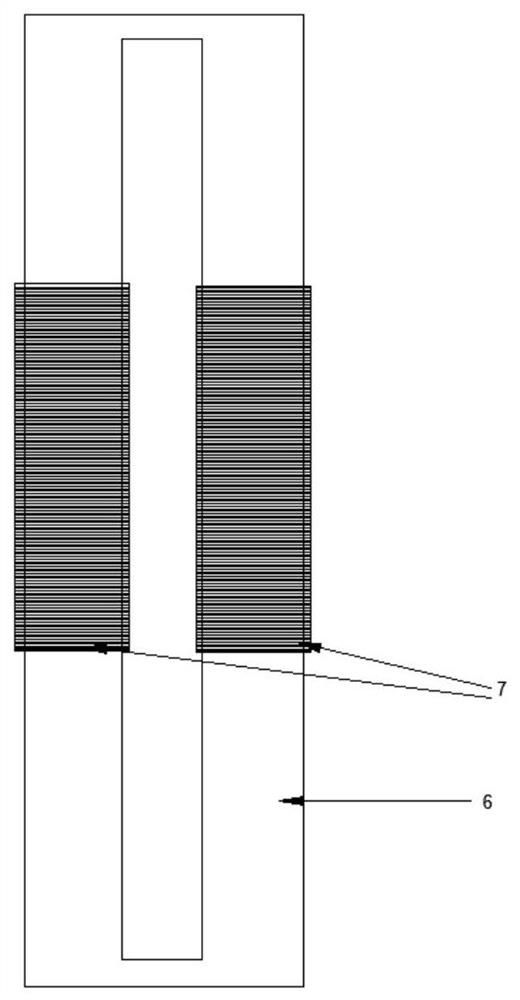

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present embodiment provides a superconducting maglev train, which includes a vehicle frame 1, an arm 3, a Dewar 4, a superconductor, a permanent magnet track 5, an iron core 6, a coil 7 and a power supply 8 . The arm 3 is arranged at the bottom of the frame 1; the Dewar 4 is arranged at the bottom of the frame 1; the superconductor is arranged in the Dewar 4; the permanent magnet track 5 is arranged in the Below the Dewar 4; the iron core 6 is arranged below the permanent magnet track 5; the coil 7 is sleeved on the iron core 6; end connected.

[0030] Optionally, the superconducting maglev train further includes a track body 2 on which the permanent magnet track 5 is arranged.

[0031]Optionally, two permanent magnet tracks 5 are provided, and the two permanent magnet tracks 5 are respectively arranged on both sides of the track body 2, and the two permanent magnet tracks 5 are fixed to the track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com