A kind of plane mask production equipment and production method

A technology for producing equipment and masks, applied in the field of flat mask production equipment, can solve the problems of affecting the welding quality of ear wire welding accuracy, increasing the volume of the flat mask machine, and large manufacturing costs, and achieves good product quality consistency and high yield rate. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

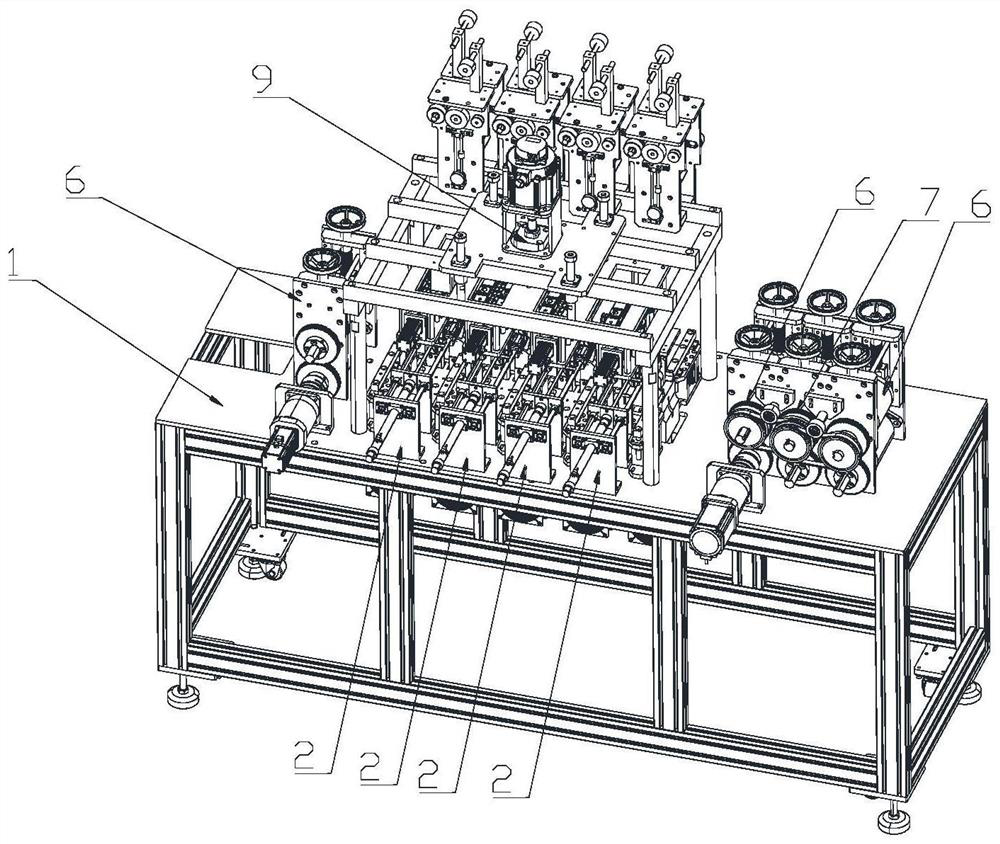

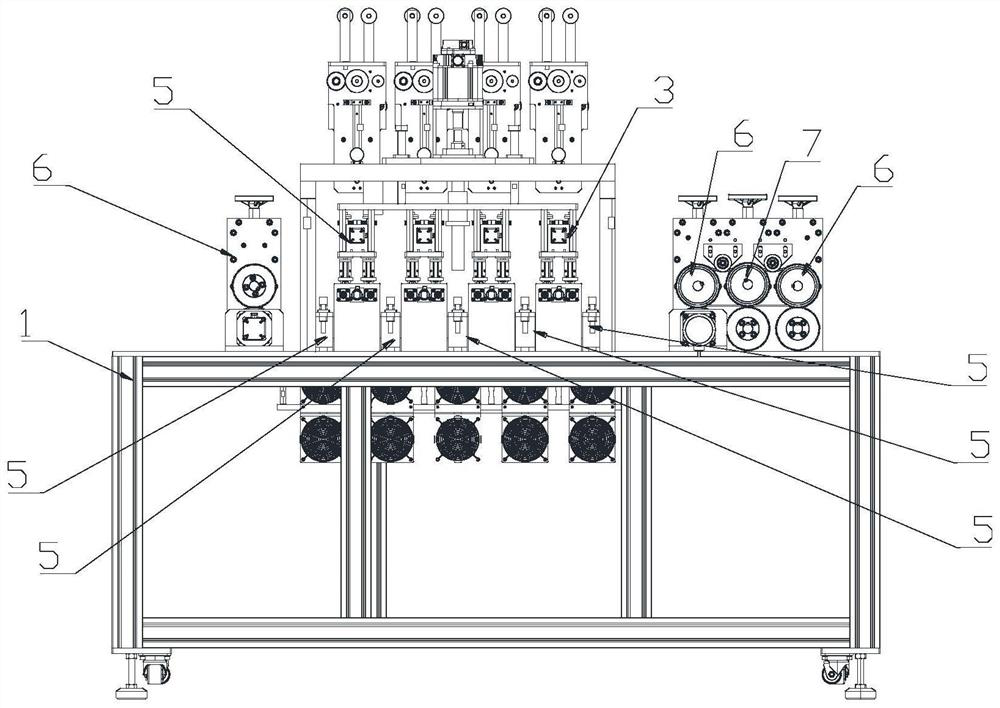

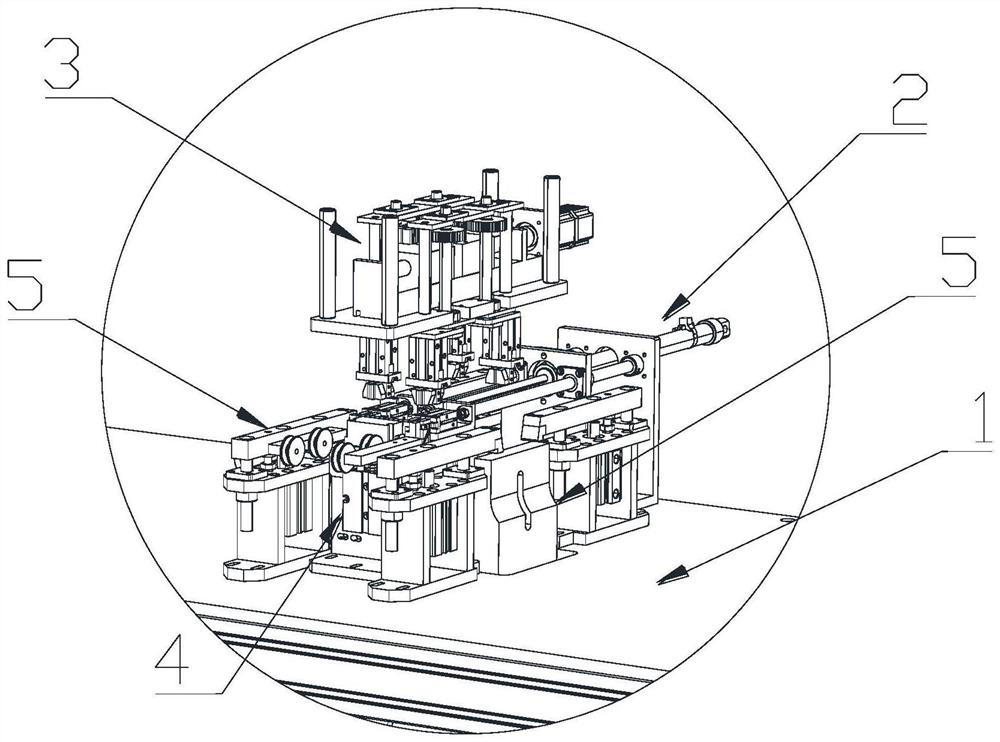

[0044] see Figure 1-Figure 13 , the plane mask production equipment of the present invention comprises frame 1, the mask coil material loading device 8 that is arranged on frame 1, preorder processing device, ear wire welding device 10, mask cutting device 7 and mask substrate conveying device 6 , wherein, the mask roll feeding device 8 is used to store the cloth for making a flat mask; the pre-order processing device is used to make the mask matrix from the cloth that the mask roll feeding device 8 sends; the ear The wire welding device 10 is used to weld the ear wire on the mask base; the mask cutting device 7 is used to cut the mask base that completes the ear wire welding into an independent plane mask; the mask base conveying device 6 is used for traction The clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com