Efficient aluminum profile production line and production process thereof

An aluminum profile and production line technology, applied in the high-efficiency aluminum profile production line and its production process, can solve the problems of large cutting size deviation, low production efficiency, and low air flow rate, and achieve accurate sawing section size without deformation and high production efficiency , The effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

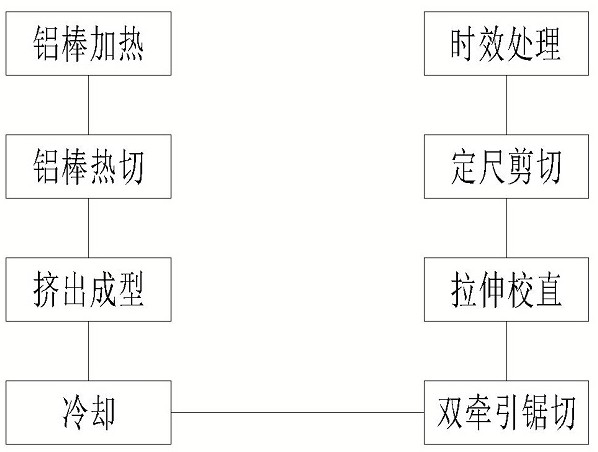

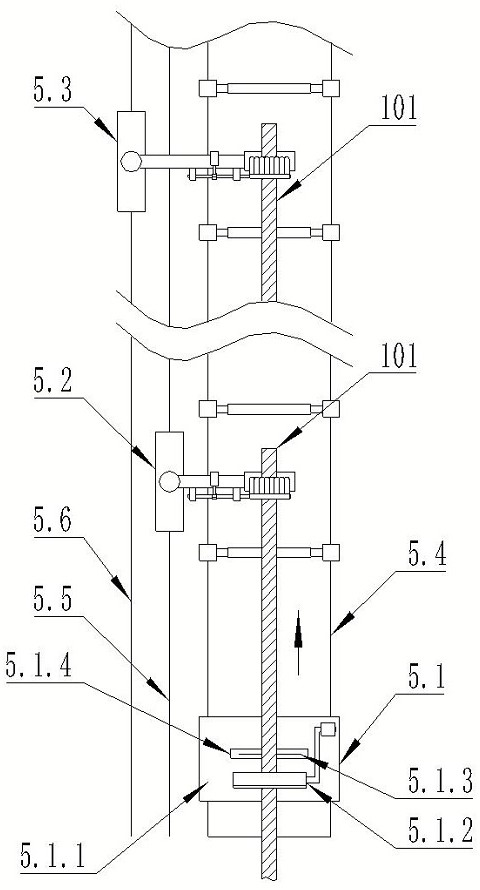

[0040] see Figure 1~7 , the present invention relates to a high-efficiency aluminum profile production line and its production process. The high-efficiency aluminum profile production line is based on a high-efficiency aluminum profile production line. The high-efficiency aluminum profile production line includes heating furnaces 1 arranged in sequence , hot cutting machine 2, extruder 3, air cooling device 4, double traction sawing device 5, straightening mechanism 6, length shearing mechanism 7 and aging treatment furnace 8;

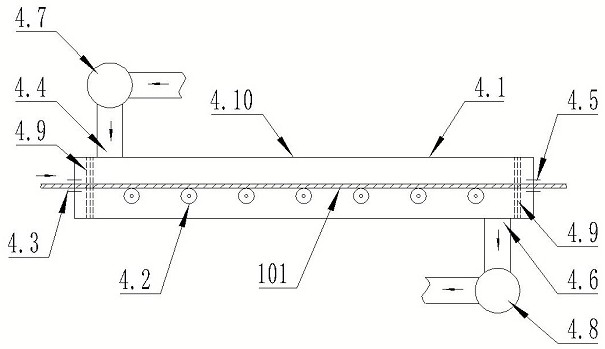

[0041] The air cooling device 4 includes a wind box 4.1 and a plurality of supporting rollers 4.2 arranged in the wind box 4.1; the left end of the wind box 4.1 is provided with a profile inlet 4.3 and an air inlet 4.4, and the right end of the bellows 4.1 is provided with a profile outlet 4.5 and an air outlet 4.6 The air inlet 4.4 is connected with the air inlet fan 4.7, and the air outlet 4.6 is connected with the air outlet fan 4.8; the profile in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com