Oil well pump for oil field

A technology for oil well pumps and oil fields, applied in the direction of pumps, parts of pumping devices for elastic fluids, pump elements, etc., can solve the problem of sticking to the inner wall of the pump barrel 2, reducing the efficiency of the oil well pump, and occupying the negative pressure area Space and other issues, to achieve the effect of increasing the service life, reducing sand concentration, and reducing direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

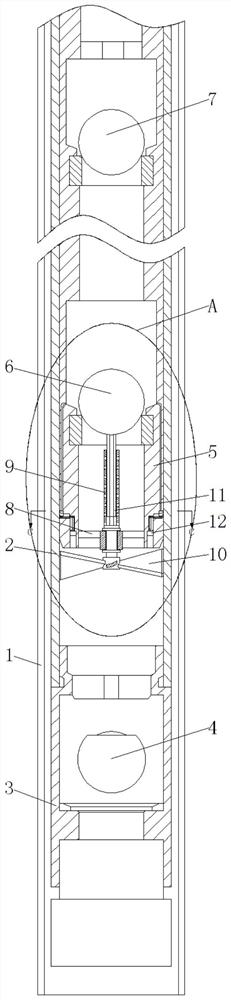

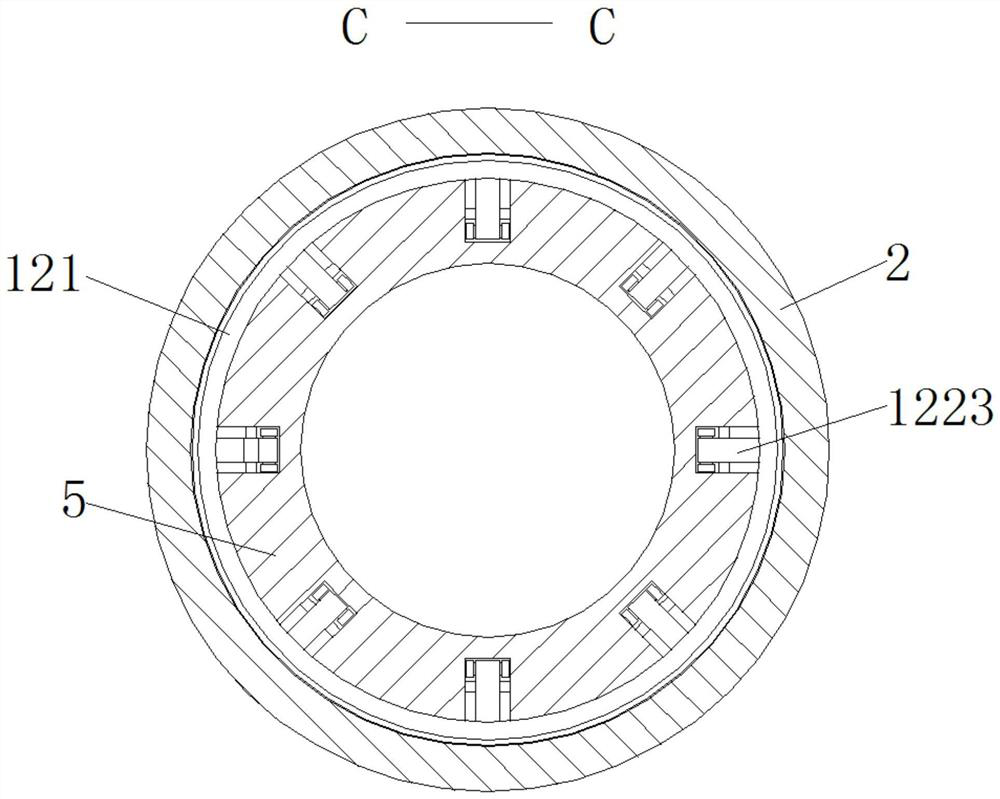

[0024] See Figure 1-7 An oilfield pump, including an oil, pump oil into the cylinder chamber 3 and a bottom end, the pump cylinder 2 and the socket 1 is fixed to the well, into the oil chamber 3 to the top of the pump cylinder 2 is fixedly connected to the 2, into the oil chamber 3 is attached inside the active sealing ball 4, the internal pump cylinder of the plunger 2 activity socket 5, the pump cylinder 2 is fitted with a gap into the oil chamber 3, the piston 5 is mounted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com