Combined drill

A combination drill bit and drill bit technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling, etc., can solve the problems of high resistance, inability to drill, low hole formation rate, poor quality, etc., to solve the problem of collapsed holes and drill sticking, and to facilitate production , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

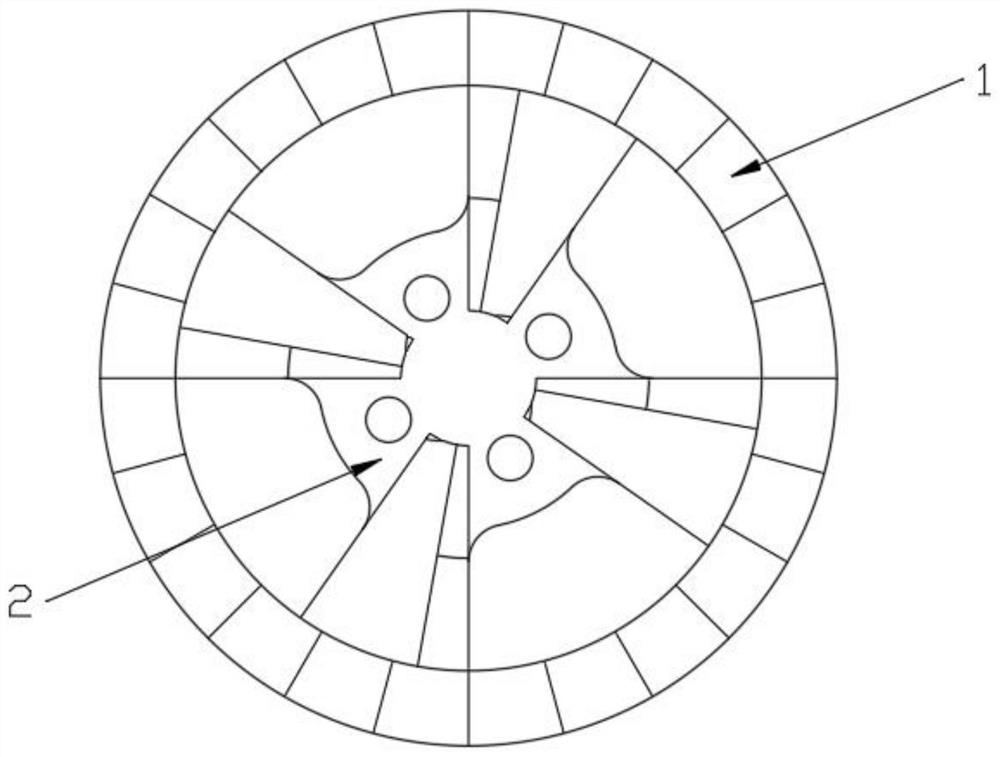

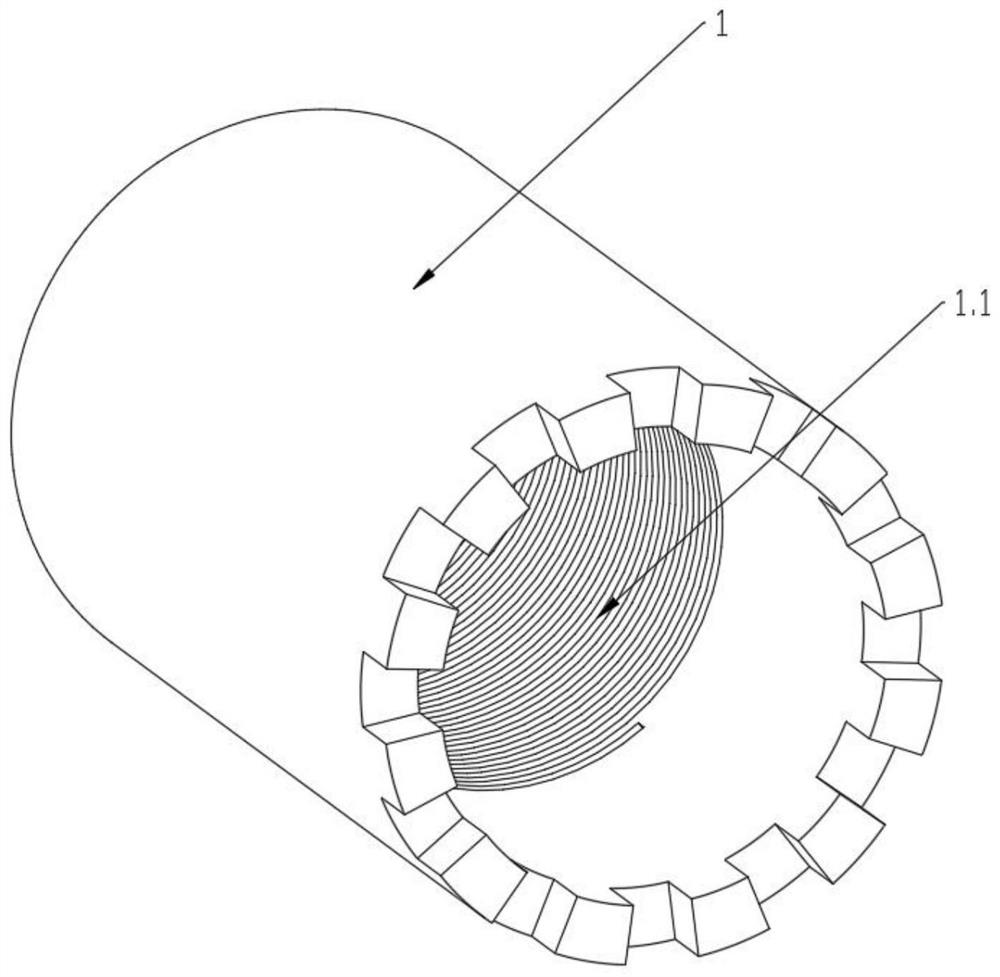

[0019] combined with figure 1 , 3 , 4, a combination drill bit, comprising a first drill bit 1, a second drill bit 2, the first drill bit 1 is cylindrical, its interior is coaxially provided with a second drill bit 2 connected thereto, the first drill bit 1 and A plurality of drainage grooves 2.4 are arranged between the second drill bits 2 for outputting slag flow from the inside of the drill bits, and the drainage grooves 2.4 are evenly arranged on the outer ring of the second drill bit 2 along the axial direction of the second drill bit 2 Above, the middle part of the second drill bit 2 is provided with a through-hole 2.5 for inputting water flow, and the head of the second drill bit 2 is arranged at a certain distance away from the axial end of the head of the first drill bit 1. The first drill bit 1 is flush with the tail of the second drill bit 2, and the second drill bit 2 is connected with the drill rod.

[0020] As a preferred implementation of this embodiment, the ...

Embodiment 2

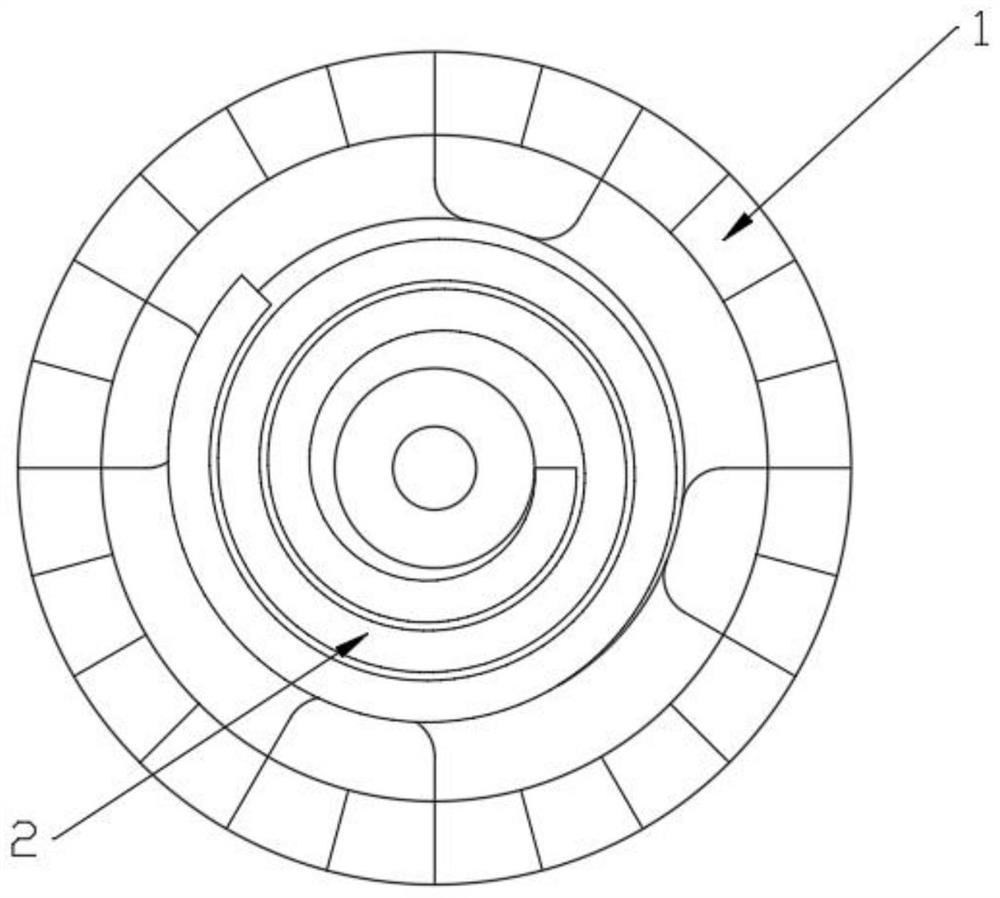

[0023] combined with figure 2 , 3 , 5, a kind of combination drill bit, comprise first drill bit 1, second drill bit 2, described first drill bit 1 is cylindrical shape, and its inside is coaxially provided with and connects second drill bit 2, described first drill bit 1 and A plurality of drainage grooves 2.4 are arranged between the second drill bits 2 for outputting slag flow from the inside of the drill bits, and the drainage grooves 2.4 are evenly arranged on the outer ring of the second drill bit 2 along the axial direction of the second drill bit 2 Above, the middle part of the second drill bit 2 is provided with a through-hole 2.5 for inputting water flow, and the head of the second drill bit 2 is arranged at a certain distance away from the axial end of the head of the first drill bit 1. The first drill bit 1 is flush with the tail of the second drill bit 2, and the second drill bit 2 is connected with the drill rod.

[0024] As a preferred implementation of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com