A self-priming positioning and measuring auxiliary device and its use method

A technology for positioning measurement and auxiliary equipment, which is applied to measuring instruments, measuring devices, measuring inclinations, etc., can solve the problems of poor safety, low operation efficiency, and high labor intensity, so as to prevent safety accidents, improve measurement accuracy and work. Efficiency and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

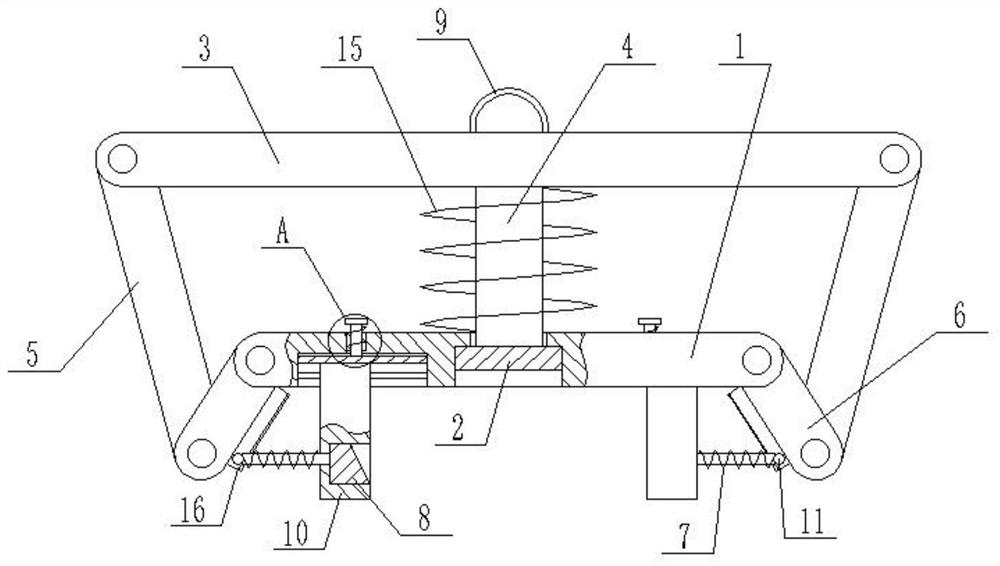

[0029] refer to Figure 1 to Figure 2 As shown, a self-priming positioning and measuring auxiliary equipment includes a fixed plate 1, which is connected with two positioning mechanisms. Connect the adsorption piece 2, a moving plate 3 is arranged above the fixed plate 1, and a connecting piece 4 is fixedly connected to the moving plate 3, and the end of the connecting piece 4 away from the moving plate 3 extends into the stepped hole and is fixedly connected with the absorbing piece 2, moving Both ends of the plate 3 are rotatably connected with a connecting rod 1 5, and the ends of the two connecting rod 1 5 away from the moving plate 3 are rotatably connected with a connecting rod 2 6, and the two connecting rod 2 6 are rotatably connected to the fixed plate 1 respectively. At both ends, two connecting rods 26 are used to drive the corresponding positioning mechanism.

[0030] When the measurement auxiliary equipment is installed, the adsorption part 2 will automatically m...

Embodiment 2

[0045] A method for using a self-priming positioning and measuring auxiliary device, comprising the following steps:

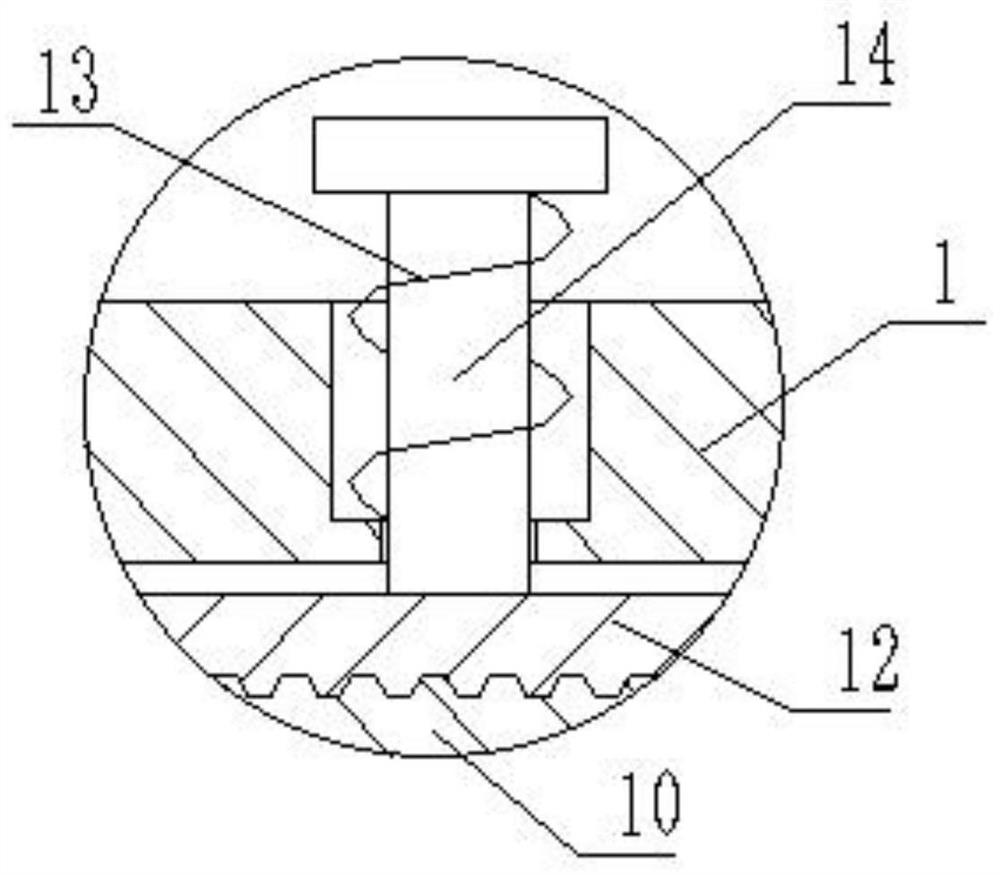

[0046] Step 1: First pull the pull rod 14 upwards, and the pull rod 14 drives the acupressure block 12 to move upward, so that the teeth on the acupressure block 12 and the teeth on the fixed block 10 are separated, and the fixed block 10 is moved to a distance equal to the width of the steel structure ;

[0047] Step 2: Then loosen the pull rod 14, and the pull rod drives the acupressure block 12 to move down under the action of the return spring 2 13, so that the teeth on the acupressure block 12 mesh with the teeth on the fixed block 10, and the fixed block 10 is locked ;

[0048] Step 3: Bolt the connecting rope on the pull ring 9, first place the measurement auxiliary equipment on the steel structure, the adsorption part 2 is fixedly adsorbed on the steel structure, the adsorption part 2 drives the moving plate 3 to move downward, and the moving plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com