Plastic speed reducer, preparation method and mold for molding plastic speed reducer box body

A reducer, injection mold technology, applied in mechanical equipment, electromechanical devices, control mechanical energy and other directions, can solve the problems of increasing gear wear, meshing angle changes, affecting life, etc., to increase service life, good meshing accuracy, and prolong service life. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0049] The first preferred embodiment:

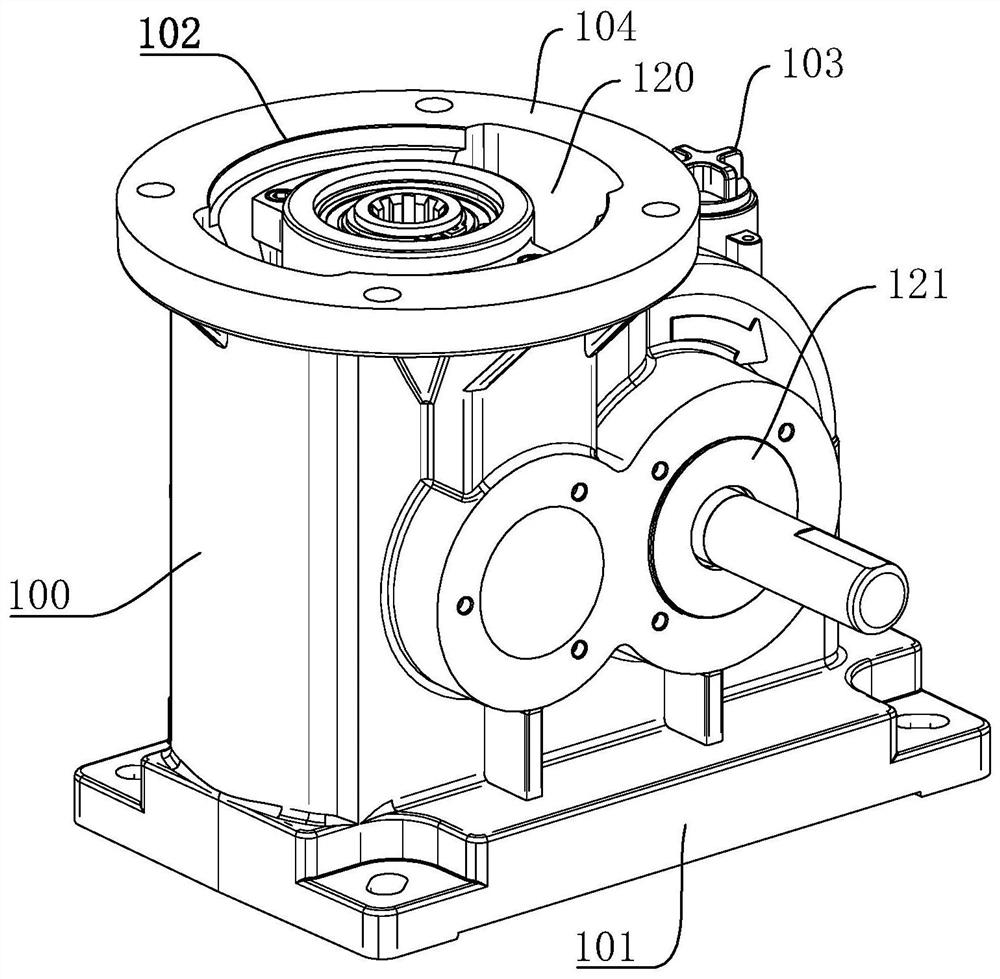

[0050] A plastic reducer, such as figure 1 As shown, a box body 100 is included. The box body 100 has a chamber inside, a base 101 at the bottom, a connection port 102 and an oil seal port 103 at the top, and a flange 104 is provided on the connection port 102 . The plastic reducer is used in the aquaculture industry and needs to be immersed in water. Therefore, considering its own weight, corrosion resistance and aging resistance, the box body 100 is made of plastic, and the molding plastic used is PA66, which is engineering plastic. Compared with cast iron, it reduces its own weight, has better impact resistance, high mechanical strength and corrosion resistance.

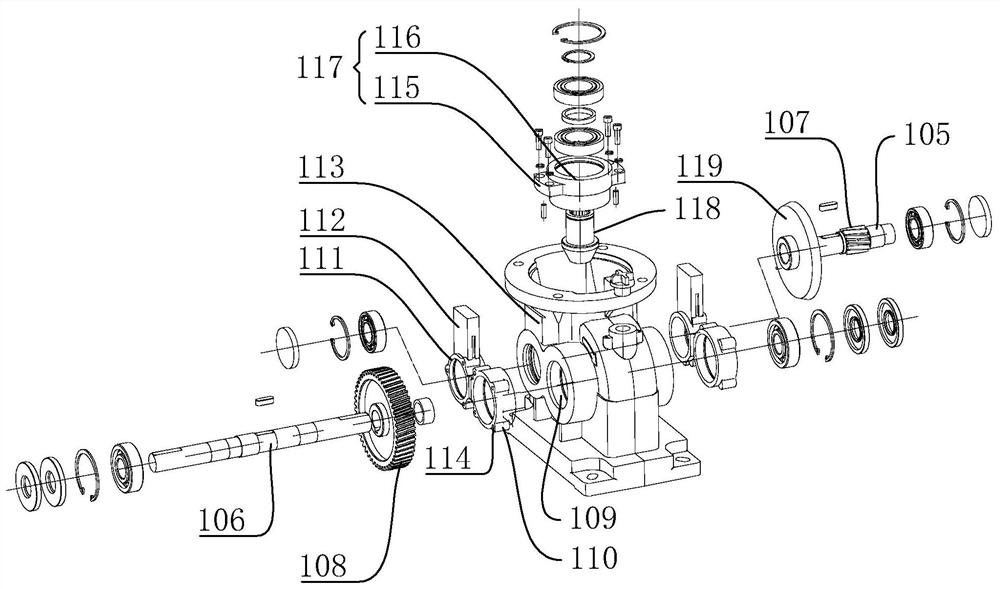

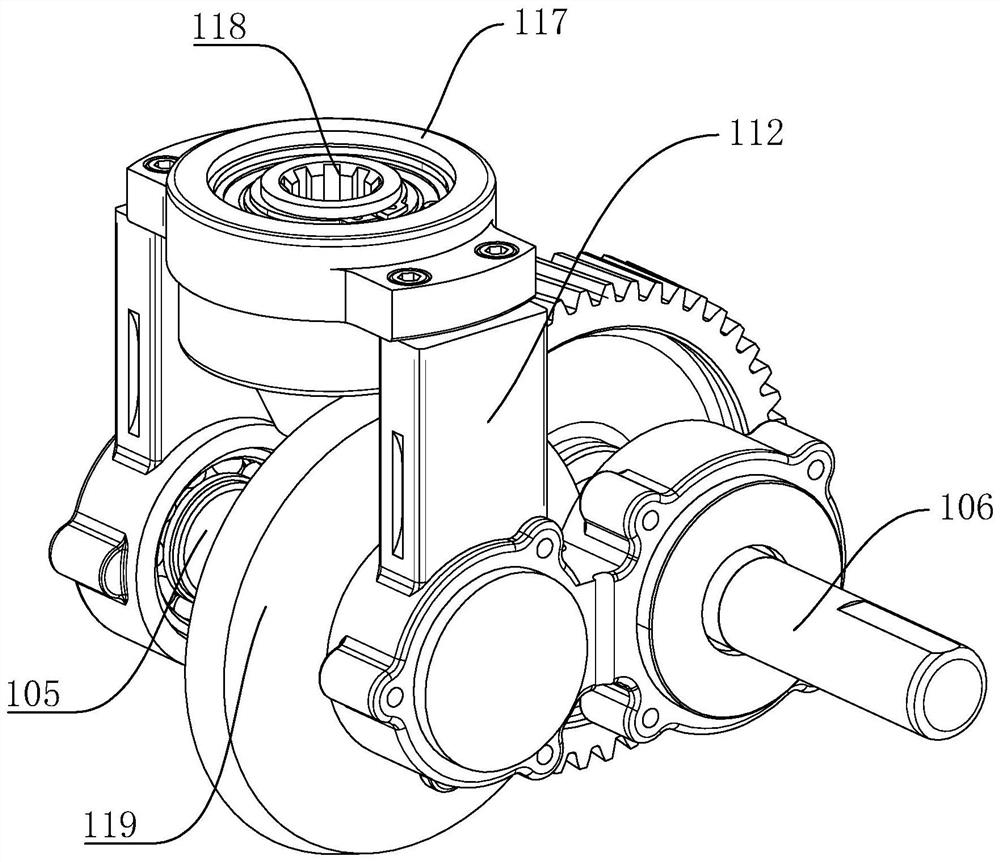

[0051] Such as figure 2 As shown, an input shaft 105 and an output shaft 106 are arranged in the chamber, and a differential gear assembly is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com