Simulation experiment method for determining thickness of rock debris bed based on measurement of fluid speed

A technology for simulating experiments and fluid velocity, applied in the field of simulating experiments, can solve the problems of failure, inaccurate measurement, high measurement cost, etc., and achieve the effect of simple determination method, convenient ground and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

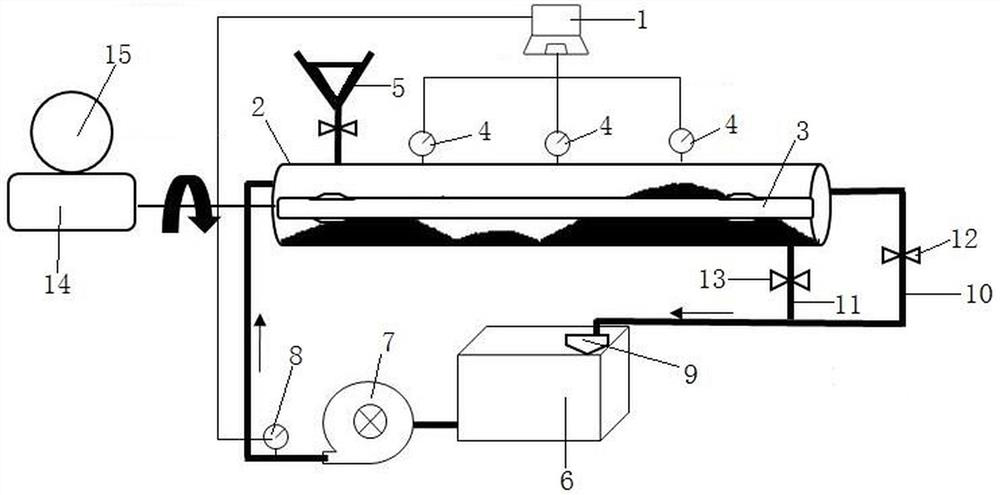

[0036] The invention discloses a simulation experiment method for judging the thickness of a cuttings bed based on measuring fluid velocity, which specifically includes the following steps:

[0037] Step 1: setting a simulated wellbore 2, and setting a simulated drill string 3 controlled by a driving mechanism in the simulated wellbore 2, and setting a flow meter 4 on the simulated wellbore 2. Wherein, the driving mechanism includes a drill string rotating device 14 and a motor 15 , and the motor 15 drives the simulated drill string 3 to rotate through the drill string rotating device 14 . The flow meter 4 is used to measure the flow velocity of the drilling fluid in the simulated wellbore 2 .

[0038] Step 2: first inject drilling fluid into the simulated wellbore 2 through the drilling fluid injection mechanism, and control the rotation of the simulated drill string 3 by the driving mechanism, and then inject cuttings into the simulated wellbore 2 through the cuttings inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com